Personal Fabrication Research in HCI and Graphics: An Overview of Related Work

Webpage maintained by Stefanie Mueller, Parinya Punpongsanon, Dishita Turakhia, M. Doga Dogan, Faraz Faruqi, and Yunyi Zhu. HCI Engineering Group, MIT CSAIL For feedback and changes, please email: stefanie.mueller/at/mit.edu

The goal of this website is to provide a resource for newcomers in the field of computational fabrication so that they can quickly access recent contributions made in the field.

This webpage serves as a related work directory - the creators of this webpage do not hold the rights for these works, please contact the authors directly.

Personal Fabrication

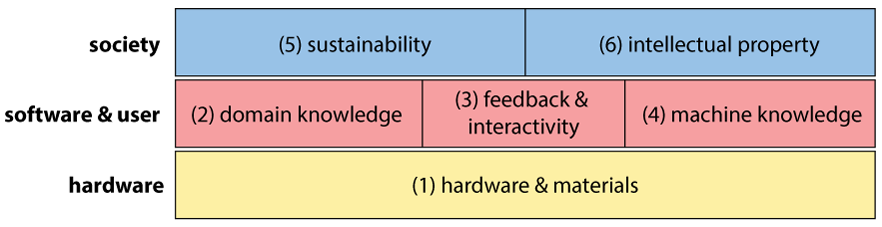

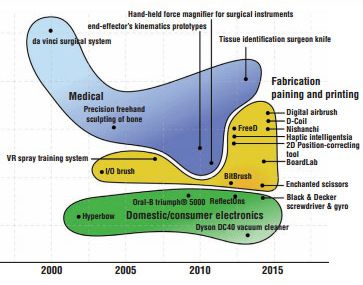

In this journal paper, we survey the related work in HCI and Computer Graphics over the last five years and

provide a roadmap for future research. The question we try to answer is whether the technology will further

progress towards consumers, which would allow the technology to scale from hundreds of thousands of users to

hundreds of millions of users. Our analysis reveals that a transition to consumers first requires a hardware +

software system that embodies the skills and expert knowledge that consumers lack [...]

DOI

PDF

2022

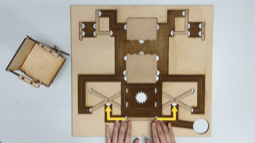

Shape-Haptics: Planar & Passive Force Feedback Mechanisms for Physical Interfaces (ACM CHI 2022)

We present Shape-Haptics, an approach for designers to rapidly design and fabricate passive force feedback mechanisms for physical interfaces. Such mechanisms are used in everyday interfaces and tools, and they are challenging to design. Shape-Haptics abstracts and broadens the haptic expression of this class of force feedback systems through 2D laser cut configurations that are simple to fabricate. They leverage the properties of polyoxymethylene plastic and comprise a compliant spring structure that engages with a sliding profile during tangible interaction. By shaping the sliding profile, designers can easily customize the haptic force feedback delivered by the mechanism. We provide a computational design sandbox to facilitate designers to explore and fabricate Shape-Haptics mechanisms. We also propose a series of applications that demonstrate the utility of Shape-Haptics in creating and customizing haptics for different physical interfaces.

DOI

PDF

Video

Page

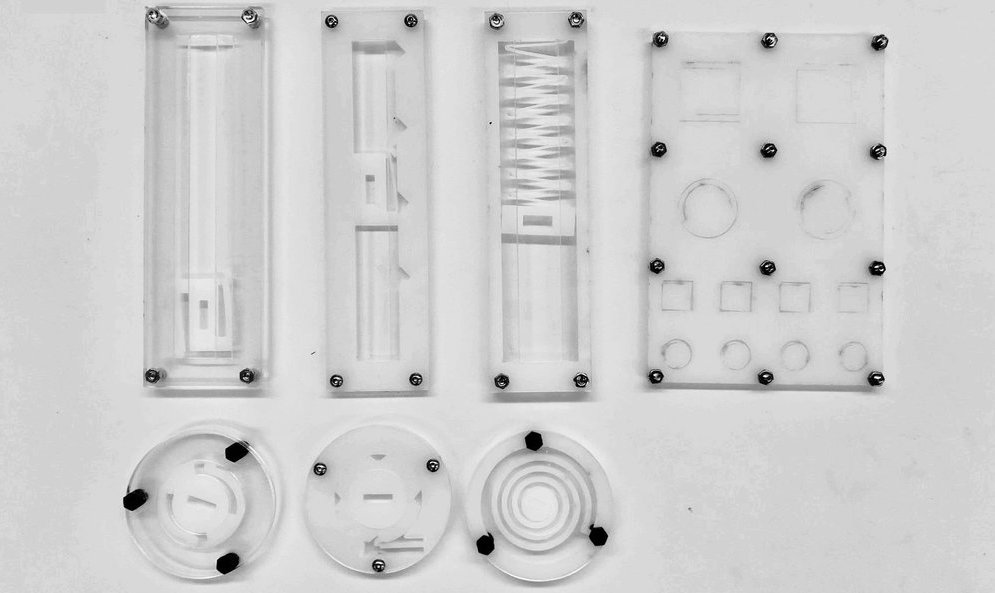

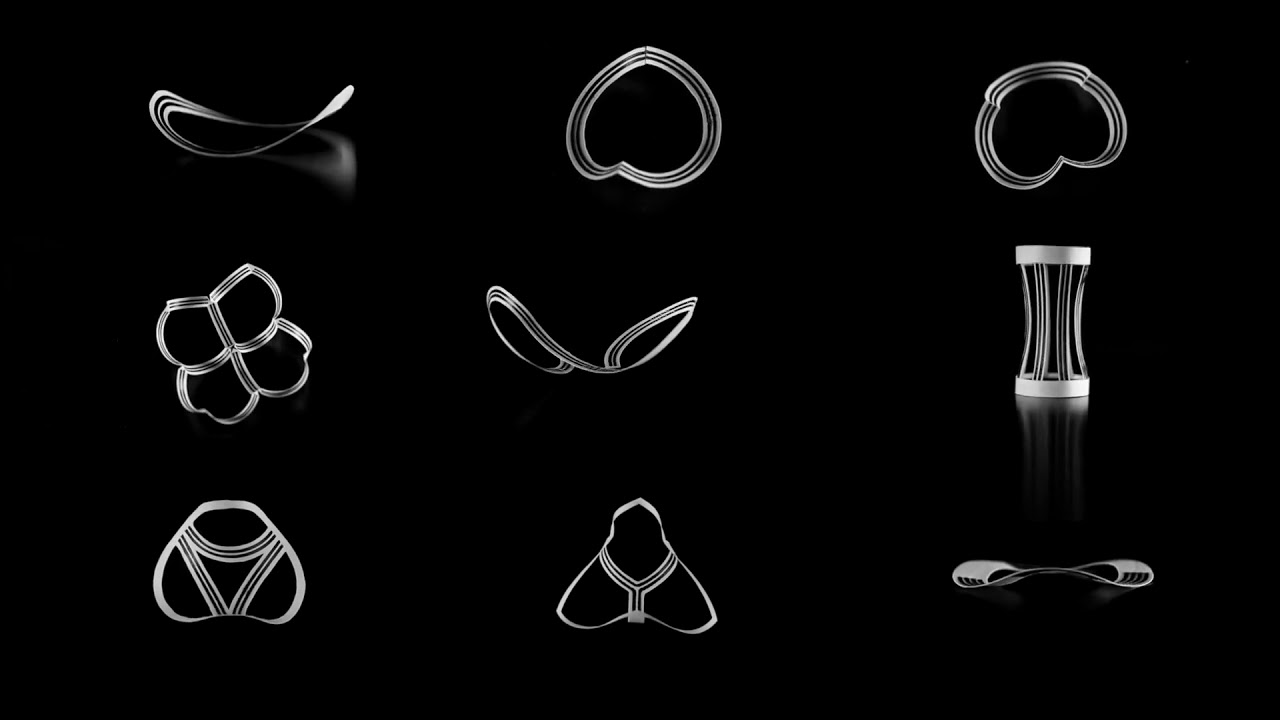

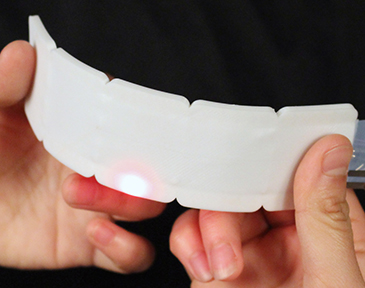

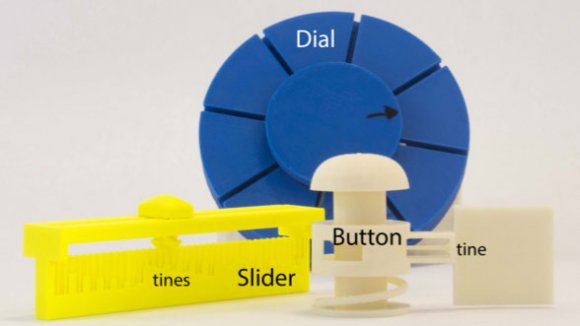

FlexHaptics: A Design Method for Passive Haptic Inputs Using Planar Compliant Structures (ACM CHI 2022)

This paper presents FlexHaptics, a design method for creating custom haptic input interfaces. Our approach leverages planar compliant structures whose force-deformation relationship can be altered by adjusting the geometries. Embedded with such structures, a FlexHaptics module exerts a fine-tunable haptic effect (i.e., resistance, detent, or bounce) along a movement path (i.e., linear, rotary, or ortho-planar). These modules can work separately or combine into an interface with complex movement paths and haptic effects. To enable the parametric design of FlexHaptic modules, we provide a design editor that converts user-specified haptic properties into underlying mechanical structures of haptic modules. We validate our approach and demonstrate the potential of FlexHaptic modules through six application examples, including a slider control for a painting application and a piano keyboard interface on touchscreens, a tactile low vision timer, VR game controllers, and a compound input device of a joystick and a two-step button.

DOI

PDF

Video

Page

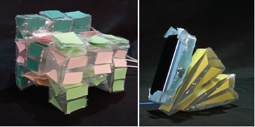

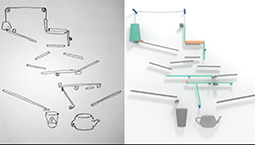

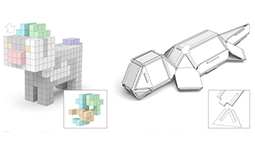

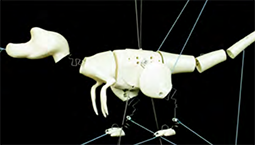

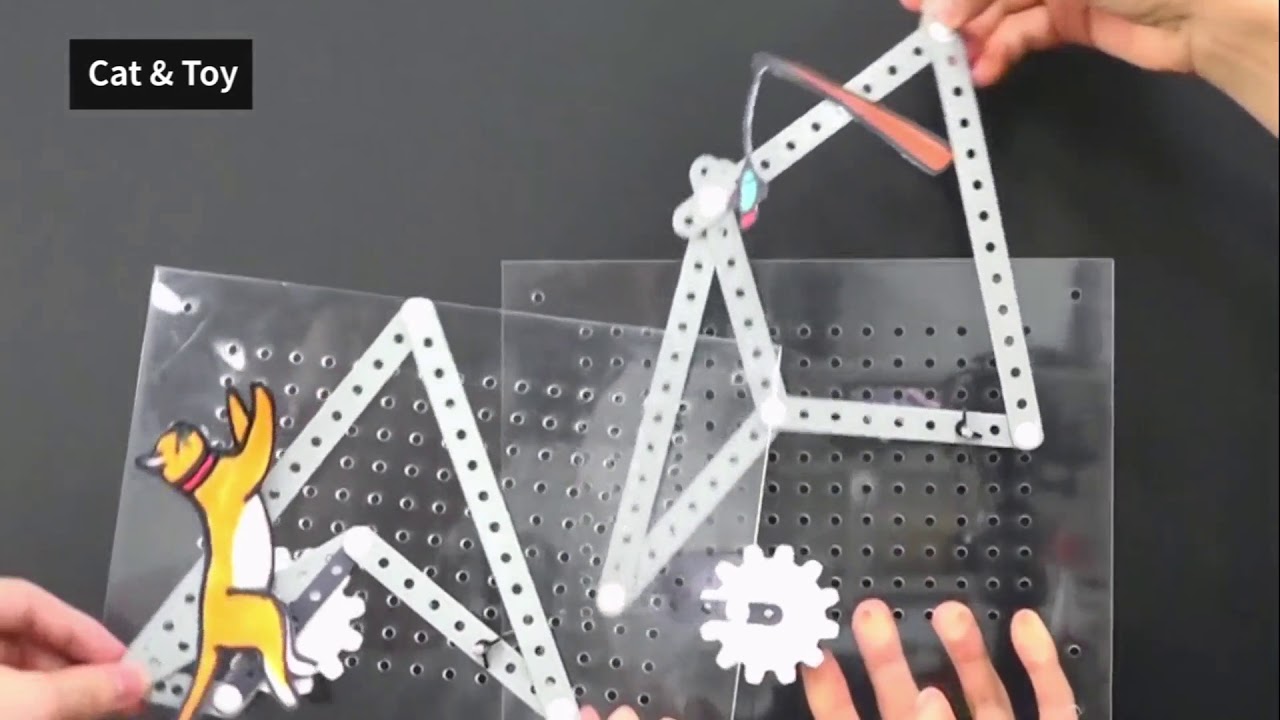

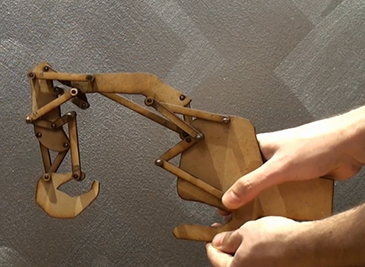

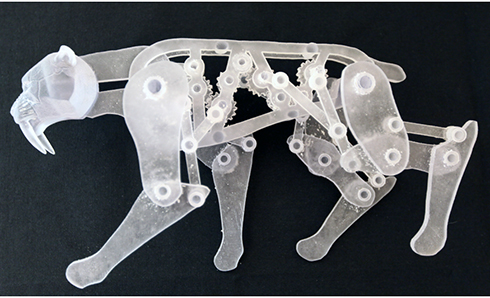

ReCompFig: Designing Dynamically Reconfigurable Kinematic Devices Using Compliant Mechanisms and Tensioning Cables (ACM CHI 2022)

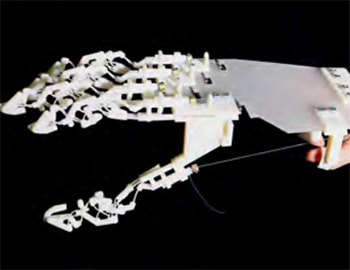

From creating input devices to rendering tangible information, the field of HCI is interested in using kinematic mechanisms to create human-computer interfaces. Yet, due to fabrication and design challenges, it is often difficult to create kinematic devices that are compact and have multiple reconfigurable motional degrees of freedom (DOFs) depending on the interaction scenarios. In this work, we combine compliant mechanisms (CMs) with tensioning cables to create dynamically reconfigurable kinematic mechanisms. The devices’ kinematics (DOFs) is enabled and determined by the layout of bendable rods. The additional cables function as on-demand motion constraints that can dynamically lock or unlock the mechanism's DOFs as they are tightened or loosened. We provide algorithms and a design tool prototype to help users design such kinematic devices. We also demonstrate various HCI use cases including a kinematic haptic display, a haptic proxy, and a multimodal input device.

DOI

PDF

Video

Page

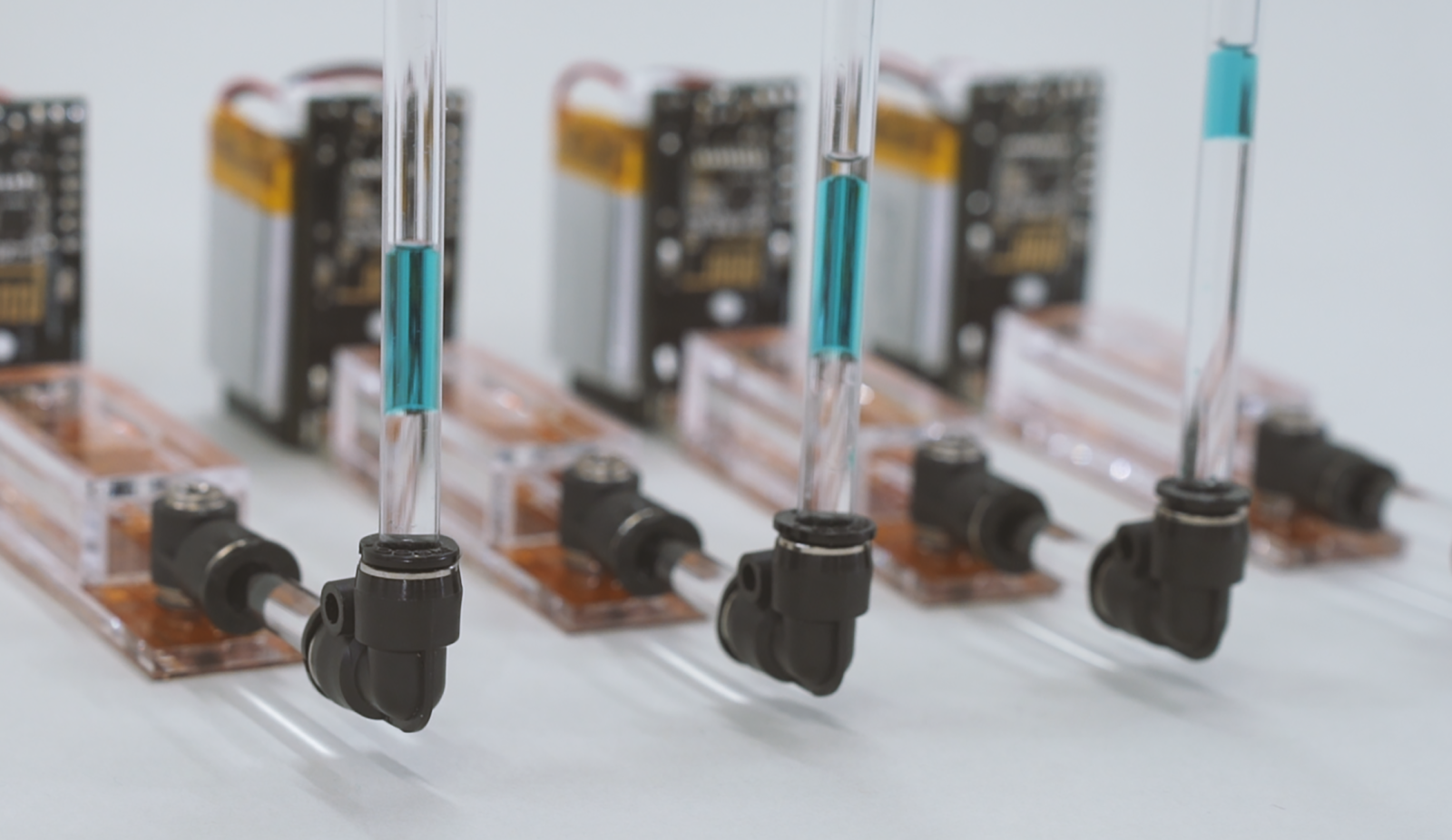

HydroMod : Constructive Modules for Prototyping Hydraulic Physical Interfaces (ACM CHI 2022)

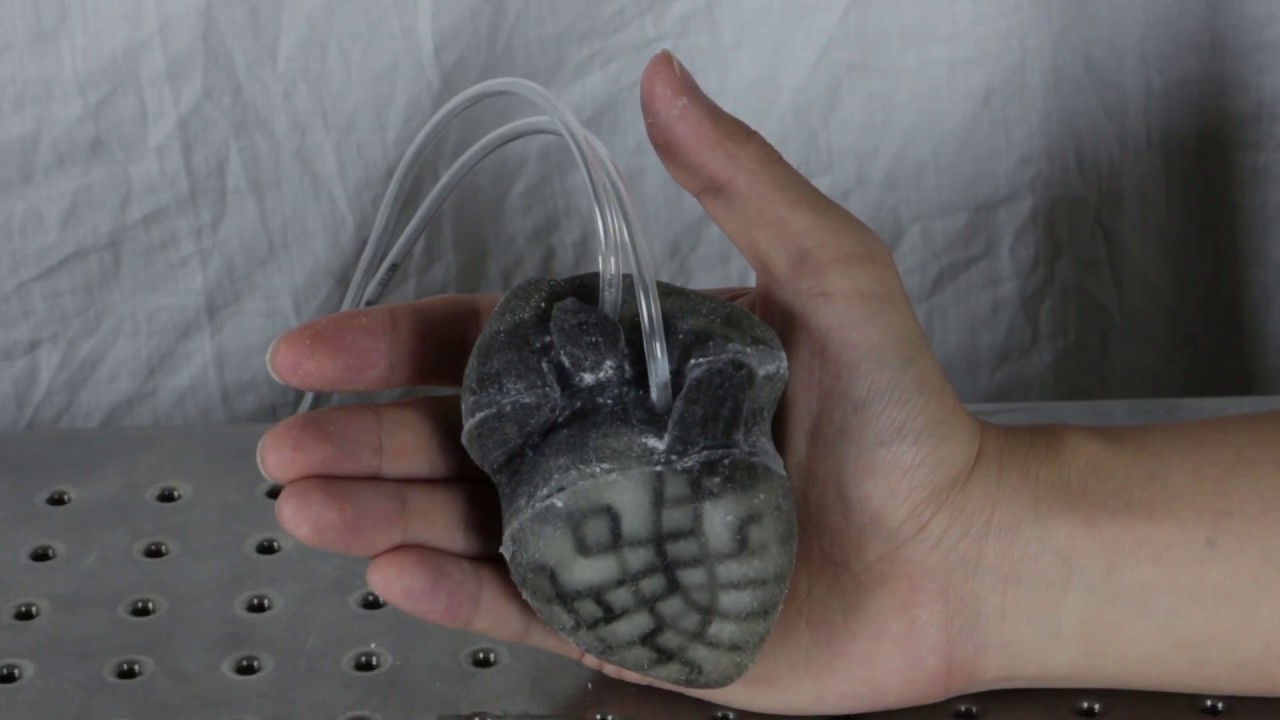

In recent years, actuators that handle fluids such as gases and liquids have been attracting attention for their applications in soft robots and shape-changing interfaces. In the field of HCI, there have been various inflatable prototyping tools that utilize air control, however, very few tools for liquid control have been developed. In this study, we propose HydroMod, new constructive modules that can easily generate liquid flow and programmatically control liquid flow, with the aim of lowering the barrier to entry for prototyping with liquids. HydroMod consists of palm-sized small modules, which can generate liquid flow with the electrohydrodynamics (EHD) phenomenon by simply connecting the modules. Moreover, users can configure and control the flow path by simply recombining the modules. In this paper, we propose the design of the modules, evaluate the performance of HydroMod as a fluid system, and also show the possible application scenarios of fluid prototyping using this system.

DOI

PDF

Video

Page

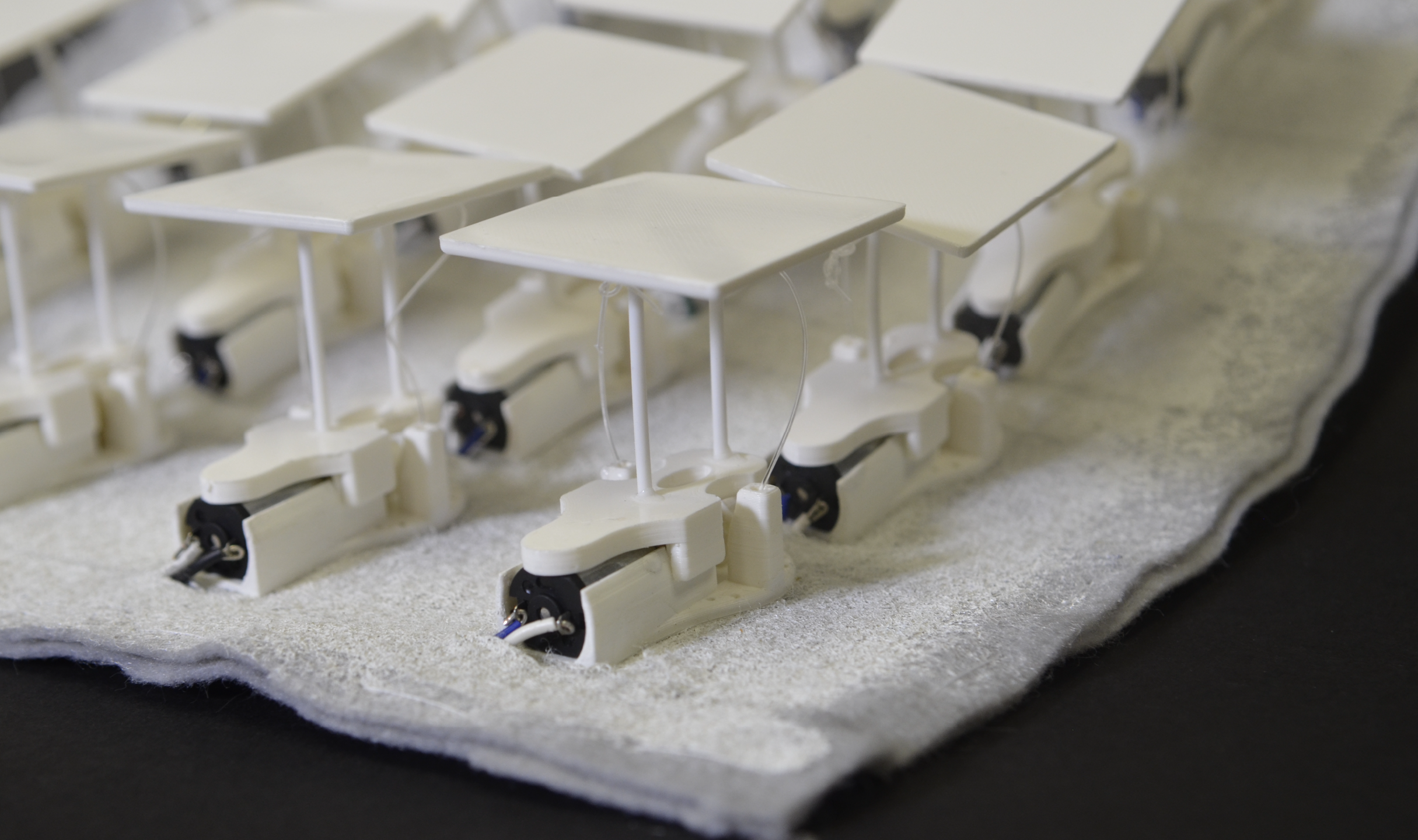

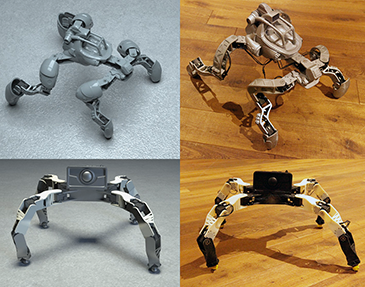

(Dis)Appearables: A Concept and Method for Actuated Tangible UIs to Appear and Disappear based on Stages (ACM CHI 2022)

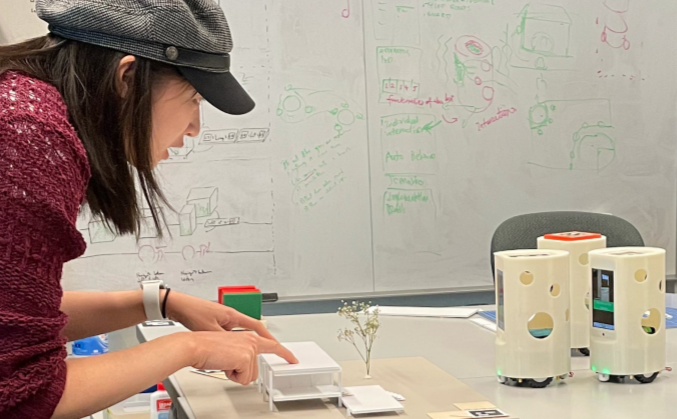

(Dis)Appearables is an approach for actuated Tangible User Interfaces (TUIs) to appear and disappear. This technique is supported by Stages: physical platforms inspired by theatrical stages. Self-propelled TUI’s autonomously move between front and back stage allowing them to dynamically appear and disappear from users’ attention. This platform opens up a novel interaction design space for expressive displays with dynamic physical affordances. We demonstrate and explore this approach based on a proof-of-concept implementation using two-wheeled robots, and multiple stage design examples. We have implemented a stage design pipeline which allows users to plan and design stages that are composed with front and back stages, and transition portals such as trap doors or lifts. The pipeline includes control of the robots, which guides them on and off stage. With this proof-of-concept prototype, we demonstrated a range of applications including interactive mobility simulation, self re-configuring desktops, remote hockey, and storytelling/gaming. Inspired by theatrical stage designs, this is a new take on ‘controlling the existence of matter’ for user experience design.

DOI

PDF

Video

Page

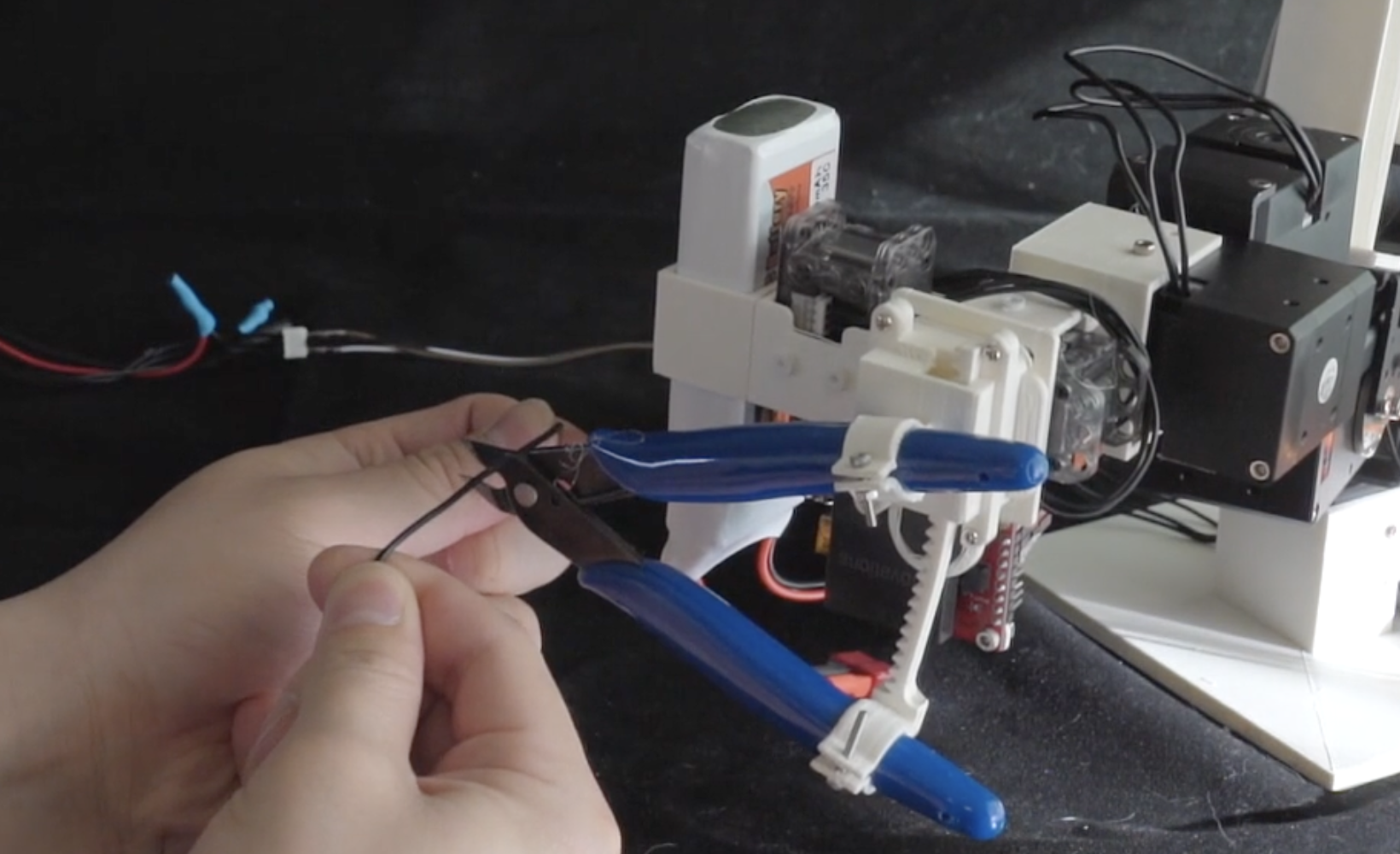

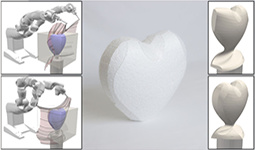

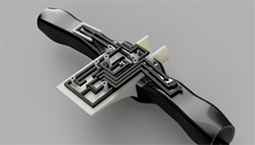

Roman: Making Everyday Objects Robotically Manipulable with 3D-Printable Add-on Mechanisms (ACM CHI 2022)

One important vision of robotics is to provide physical assistance by manipulating different everyday objects, e.g., hand tools, kitchen utensils. However, many objects designed for dexterous hand-control are not easily manipulable by a single robotic arm with a generic parallel gripper. Complementary to existing research on developing grippers and control algorithms, we present Roman, a suite of hardware design and software tool support for robotic engineers to create 3D printable mechanisms attached to everyday handheld objects, making them easier to be manipulated by conventional robotic arms. The Roman hardware comes with a versatile magnetic gripper that can snap on/off handheld objects and drive add-on mechanisms to perform tasks. Roman also provides software support to register and author control programs. To validate our approach, we designed and fabricated Roman mechanisms for 14 everyday objects/tasks presented within a design space and conducted expert interviews with robotic engineers indicating that Roman serves as a practical alternative for enabling robotic manipulation of everyday objects.

DOI

PDF

Video

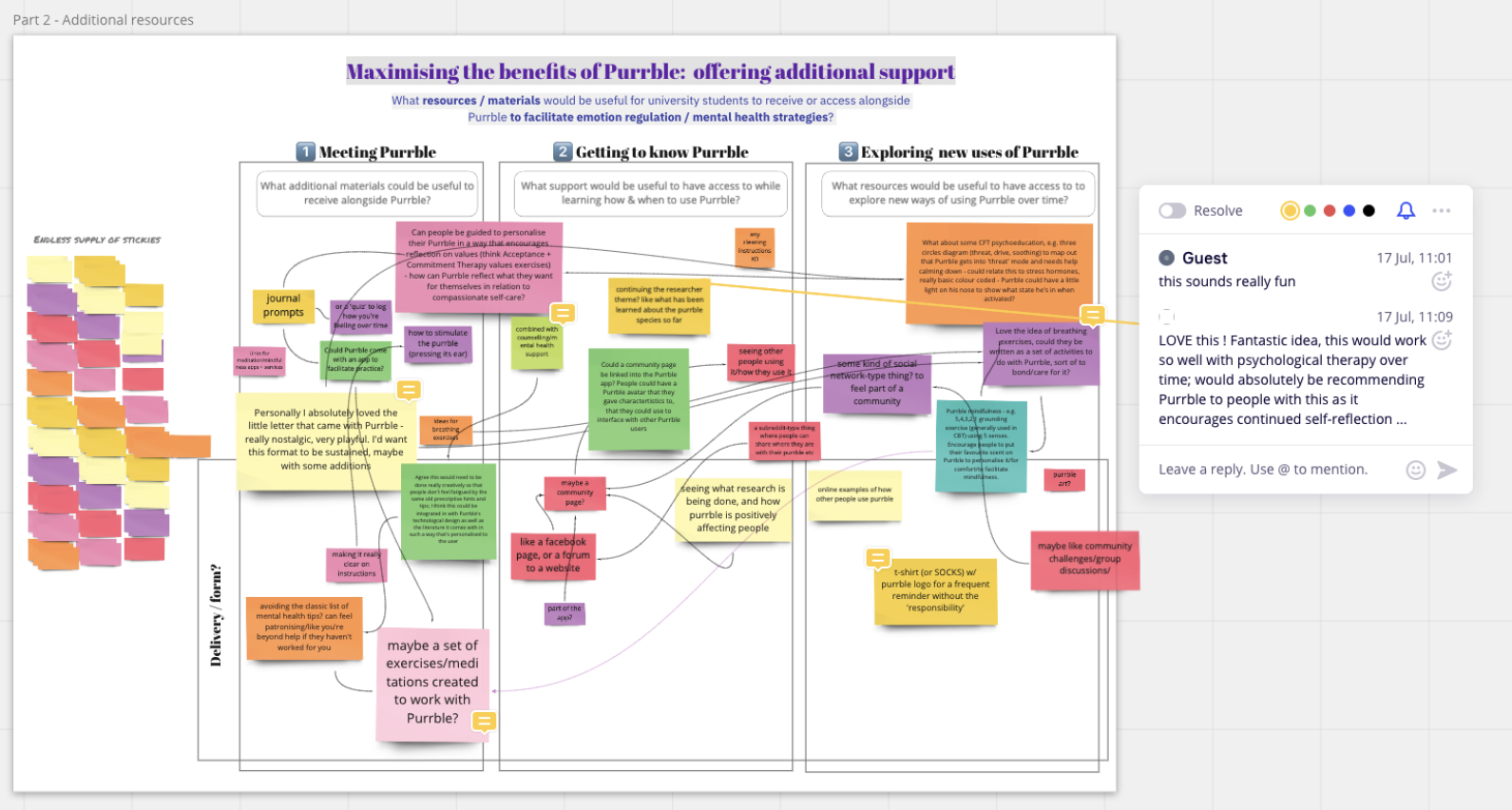

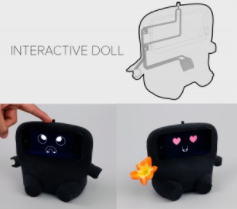

Exploring Situated & Embodied Support for Youth's Mental Health: Design Opportunities for Interactive Tangible Devices (ACM CHI 2022)

The ability to manage emotions effectively is critical to healthy psychological and social development in youth. Prior work has focused on investigating the design of mental health technologies for this population, yet it is still unclear how to help them cope with emotionally difficult situations in-the-moment. In this paper, we aim to explore the appropriation, naturally emerging engagement patterns, and perceived psychological impact of an exemplar interactive tangible device intervention designed to provide in-situ support, when deployed with n=109 youth for 1.5 months. Our findings from semi-structured interviews and co-design workshops with a subset of participants (n=44 and n=25, respectively) suggest the potential of using technology-enabled objects to aid with down-regulation and self-compassion in moments of heightened emotion, to facilitate the practice of cognitive strategies, and to act as emotional companions. Lastly, we discuss design opportunities for integrating situated and embodied support in mental health interventions for youth.

DOI

PDF

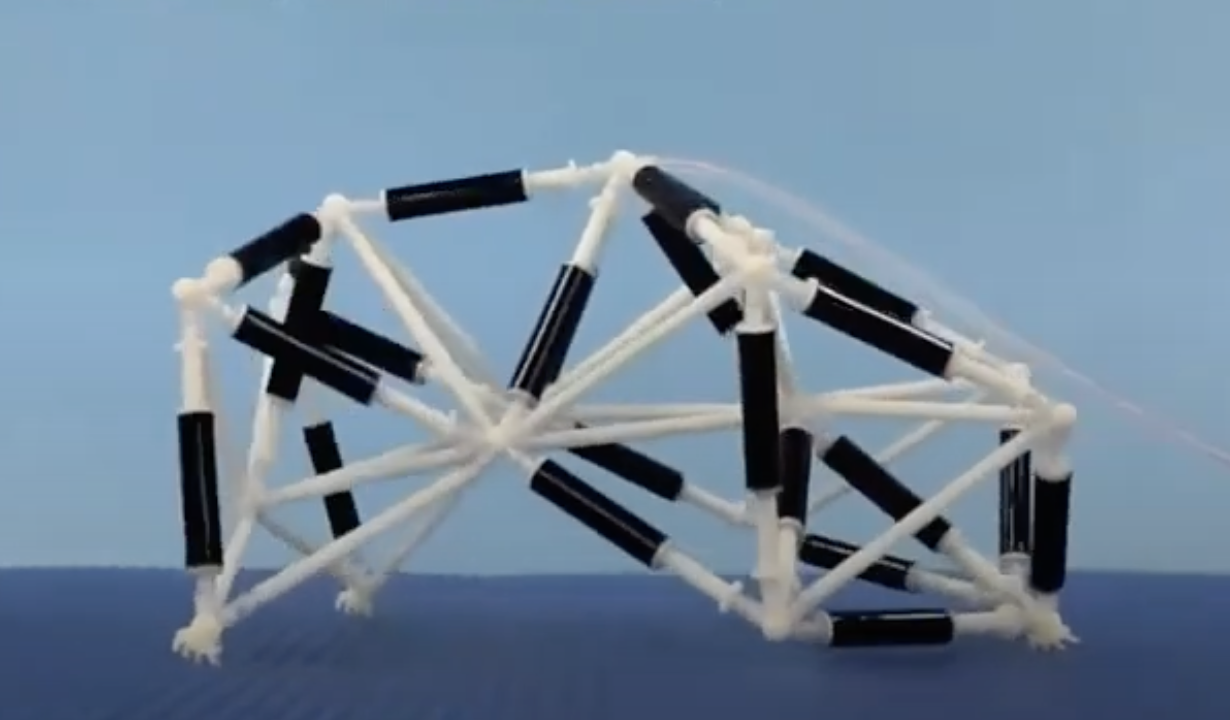

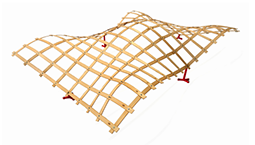

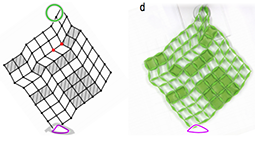

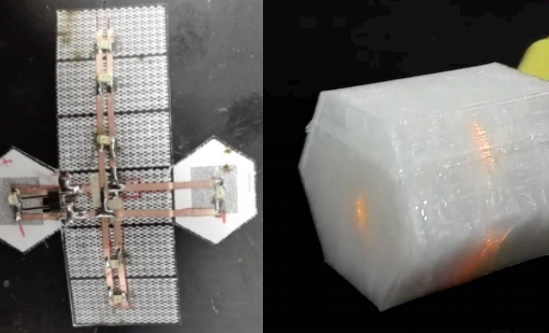

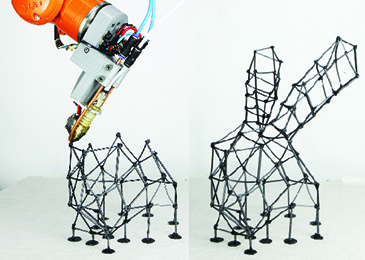

PneuMesh: Pneumatic-driven Truss-based Shape Changing System (ACM CHI 2022)

From transoceanic bridges to large-scale installations, truss structures have been known for their structural stability and shape complexity. In addition to the advantages of static trusses, truss structures have a large degree of freedom to change shape when equipped with rotatable joints and retractable beams. However, it is difficult to design a complex motion and build a control system for large numbers of trusses. In this paper, we present PneuMesh, a novel truss-based shape-changing system that is easy to design and build but still able to achieve a range of tasks. PneuMesh accomplishes this by introducing an air channel connection strategy and reconfigurable constraint design that drastically decreases the number of control units without losing the complexity of shape-changing. We develop a design tool with real-time simulation to assist users in designing the shape and motion of truss-based shape-changing robots and devices. A design session with seven participants demonstrates that PneuMesh empowers users to design and build truss structures with a wide range of shapes and various functional motions.

DOI

PDF

Video

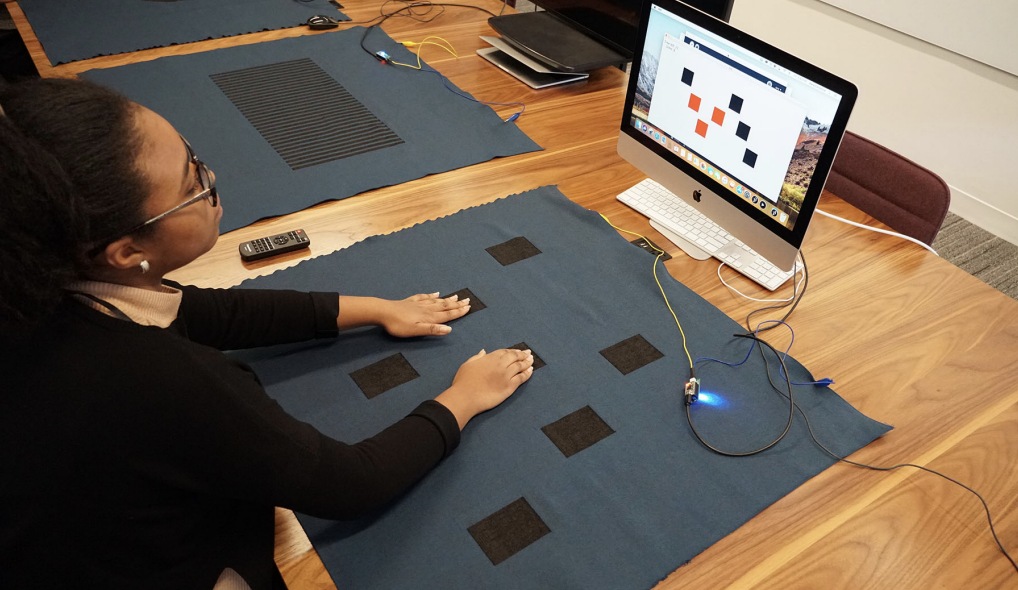

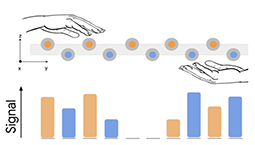

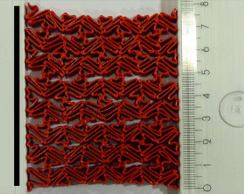

Interaction with Touch-Sensitive Knitted Fabrics: User Perceptions and Everyday Use Experiments (ACM CHI 2022)

Recent work has investigated the construction of touch-sensitive knitted fabrics, capable of being manufactured at scale, and having only two connections to external hardware. Additionally, several sensor design patterns and application prototypes have been introduced. Our aim is to start shaping the future of this technology according to user expectations. Through a formative focus group study, we explore users’ views of using these fabrics in different contexts and discuss potential concerns and application areas. Subsequently, we take steps toward addressing relevant questions, by first providing design guidelines for application designers. Furthermore, in one user study, we demonstrate that it is possible to distinguish different swipe gestures and identify accidental contact with the sensor, a common occurrence in everyday life. We then present experiments investigating the effect of stretching and laundering of the sensors on their resistance, providing insights about considerations necessary to include in computational models.

DOI

PDF

Video

Embr: A Creative Framework for Hand Embroidered Liquid Crystal Textile Displays (ACM CHI 2022)

Conductive thread is a common material in e-textile toolkits that allows practitioners to create connections between electronic components sewn on fabric. When powered, conductive threads are used as resistive heaters to activate thermochromic dyes or pigments on textiles to create interactive, aesthetic, and ambient textile displays. In this work, we introduce Embr, a creative framework for supporting hand-embroidered liquid crystal textile displays (LCTDs). This framework includes a characterization of conductive embroidery stitches, an expanded repertoire of thermal formgiving techniques, and a thread modeling tool used to simulate mechanical, thermal, and electrical behaviors of LCTDs. Through exemplar artifacts, we annotate a morphological design space of LCTDs and discuss the tensions and opportunities of satisfying the wider range of electrical, craft, cultural, aesthetic, and functional concerns inherent to e-textile practices.

DOI

PDF

Video

Page

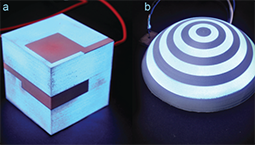

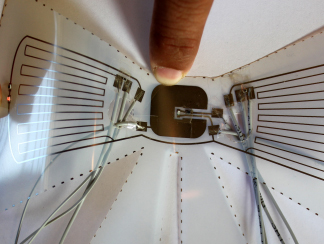

Towards Decomposable Interactive Systems: Design of a Backyard-Degradable Wireless Heating Interface (ACM CHI 2022)

Sustainability is critical to our planet and thus our designs. Within HCI, there is a tension between the desire to create interactive electronic systems and sustainability. In this paper, we present the design of an interactive system comprising components that are entirely decomposable. We leverage the inherent material properties of natural materials, such as paper, leaf skeletons, and chitosan, along with silver nanowires to create a new system capable of being electrically controlled as a portable heater. This new decomposable system, capable of wirelessly heating to >70°C, is flexible, lightweight, low-cost, and reusable, and it maintains its functionality over long periods of heating and multiple power cycles. We detail its design and present a series of use cases, from enabling a novel resealable packaging system to acting as a catalyst for shape-changing designs and beyond. Finally, we highlight the important decomposable property of the interactive system when it meets end-of-life.

DOI

PDF

Video

Page

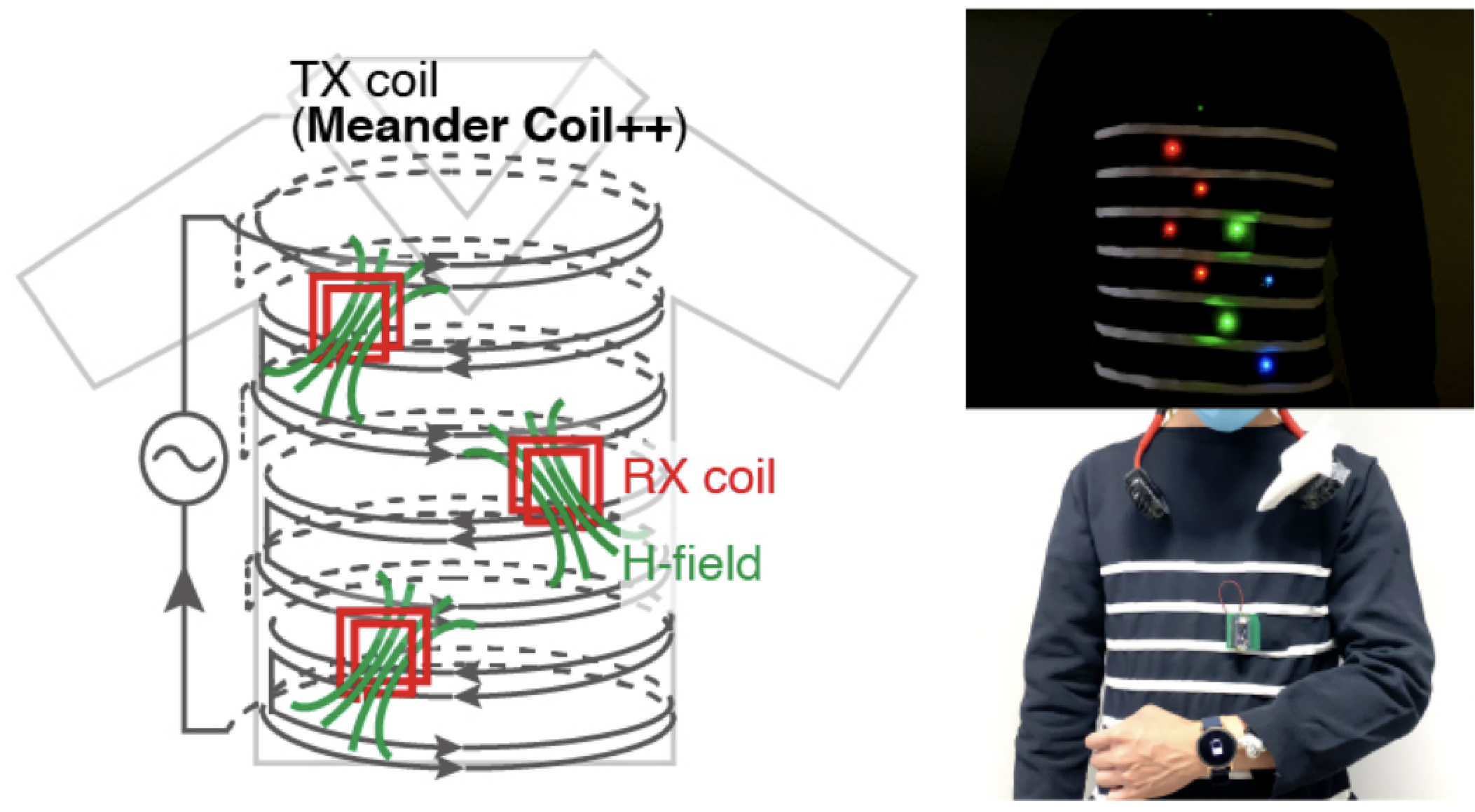

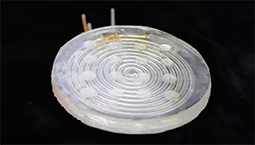

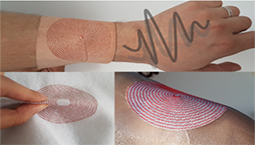

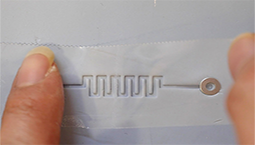

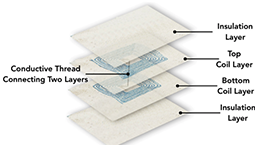

Meander Coil++: A Body-scale Wireless Power Transmission Using Safe-to-body and Energy-efficient Transmitter Coil (ACM CHI 2022)

Wearable devices for life-logging and healthcare have been studied, but the need for frequent charging imposes inconvenience for long-term use. Integrating textile-based wireless chargers (i.e., coil) into clothing enables sustainable wearable computing by charging the on-body devices in use. However, the electromagnetic field generated by conventional coil chargers strongly interferes with human body, and the high resistance of conductive threads leads to inefficient power delivery. This paper presents Meander Coil++, enabling safe, energy-efficient, and body-scale wireless power delivery. Meander Coil++ uses a wiring pattern that suppresses electromagnetic exposure to the human body without compromising power delivery performance and a liquid-metal-based low-loss conductive cord. With these advancements, Meander Coil++ transmits a few watts of power to on-body devices at 25% DC-to-DC efficiency while complying with international safety guidelines regarding electromagnetic exposure. We envision Meander Coil++ can maintain multiple devices on body for weeks beyond the confines of their small battery capacity.

DOI

PDF

Video

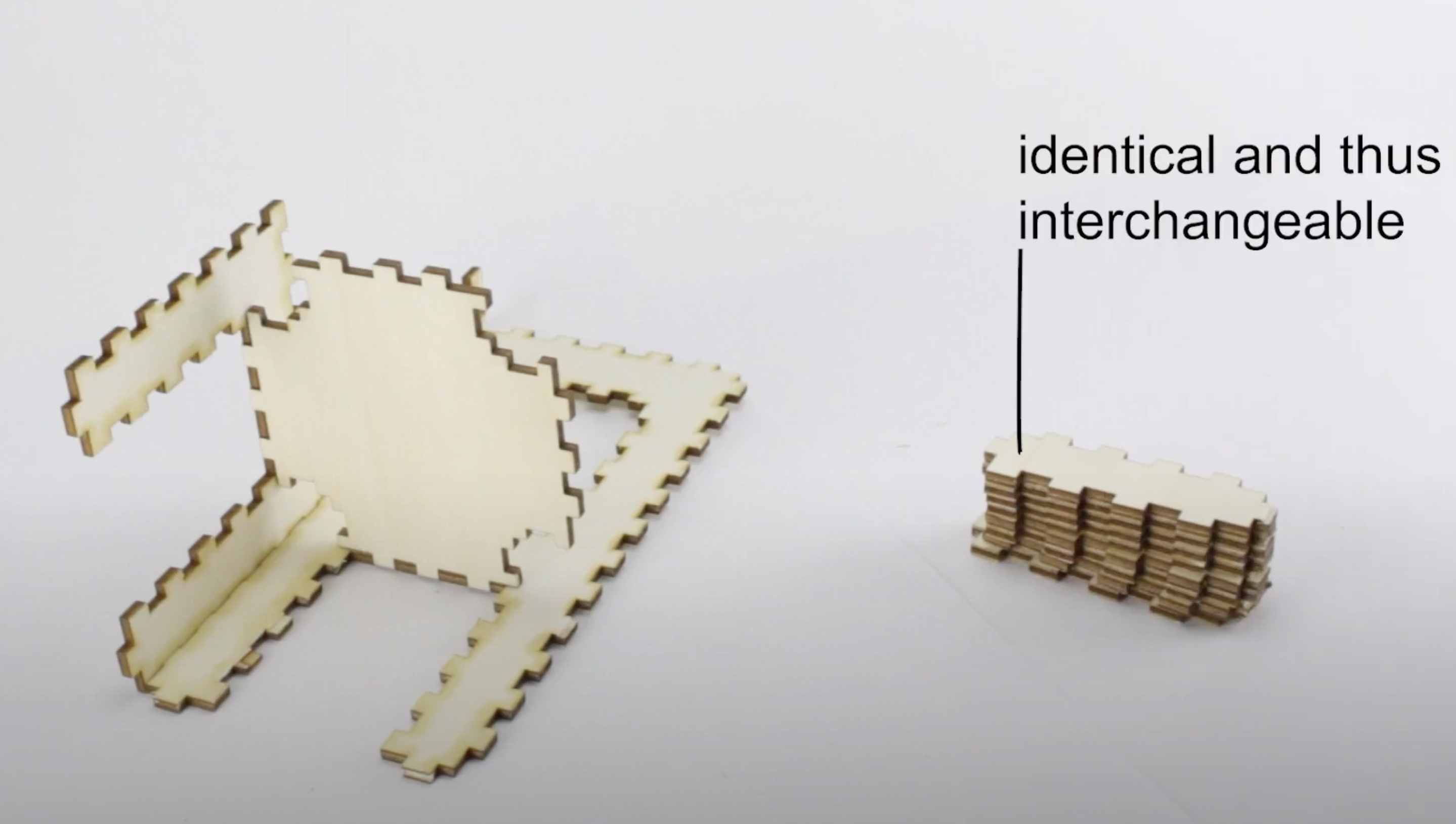

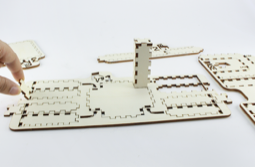

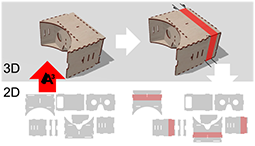

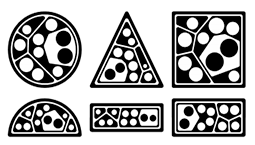

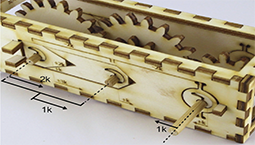

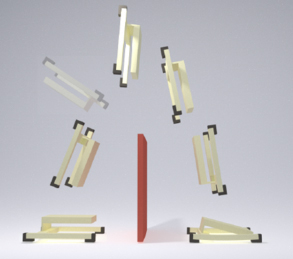

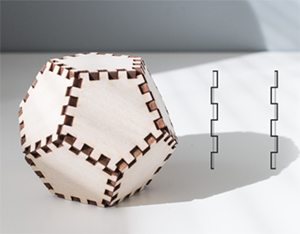

FoolProofJoint: Reducing Assembly Errors of Laser Cut 3D Models by Means of Custom Joint Patterns (ACM CHI 2022)

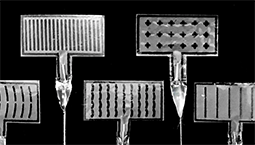

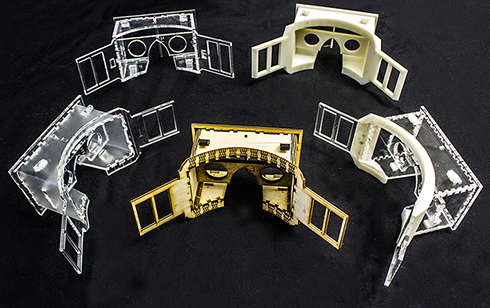

We present FoolProofJoint, a software tool that simplifies the assembly of laser-cut 3D models and reduces the risk of erroneous assembly. FoolProofJoint achieves this by modifying finger joint patterns. Wherever possible, FoolProofJoint makes similar looking pieces fully interchangeable, thereby speeding up the user's visual search for a matching piece. When that is not possible, FoolProofJoint gives finger joints a unique pattern of individual finger placements so as to fit only with the correct piece, thereby preventing erroneous assembly. In our benchmark set of 217 laser-cut 3D models downloaded from kyub.com, FoolProofJoint made groups of similar looking pieces fully interchangeable for 65% of all groups of similar pieces; FoolProofJoint fully prevented assembly mistakes for 97% of all models.

DOI

PDF

Video

Page

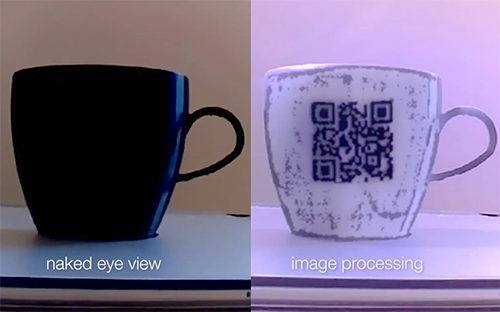

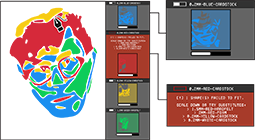

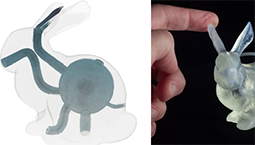

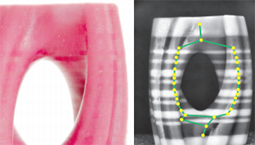

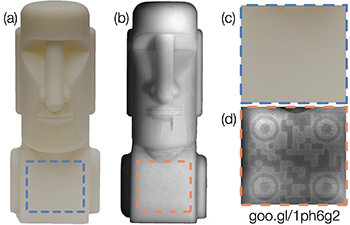

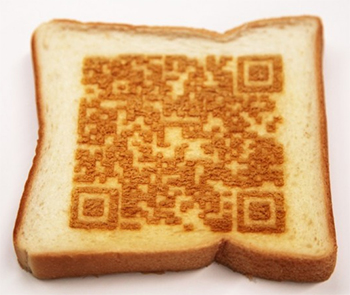

InfraredTags: Embedding Invisible AR Markers and Barcodes Using Low-Cost, Infrared-Based 3D Printing and Imaging Tools (ACM CHI 2022)

Existing approaches for embedding unobtrusive tags inside 3D objects require either complex fabrication or high-cost imaging equipment. We present InfraredTags, which are 2D markers and barcodes imperceptible to the naked eye that can be 3D printed as part of objects, and detected rapidly by low-cost near-infrared cameras. We achieve this by printing objects from an infrared-transmitting filament, which infrared cameras can see through, and by having air gaps inside for the tag’s bits, which appear at a different intensity in the infrared image. We built a user interface that facilitates the integration of common tags (QR codes, ArUco markers) with the object geometry to make them 3D printable as InfraredTags. We also developed a low-cost infrared imaging module that augments existing mobile devices and decodes tags using our image processing pipeline. Our evaluation shows that the tags can be detected with little near-infrared illumination (0.2lux) and from distances as far as 250cm. We demonstrate how our method enables various applications, such as object tracking and embedding metadata for augmented reality and tangible interactions.

DOI

PDF

Video

Page

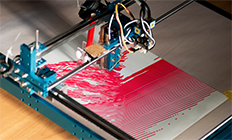

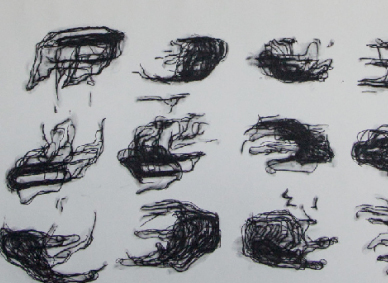

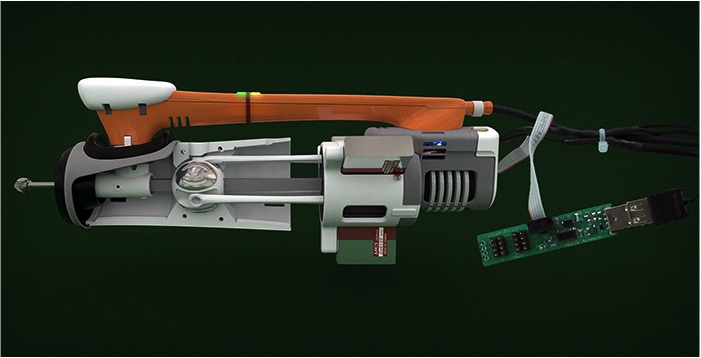

Print-A-Sketch: A Handheld Printer for Physical Sketching of Circuits and Sensors on Everyday Surfaces (ACM CHI 2022)

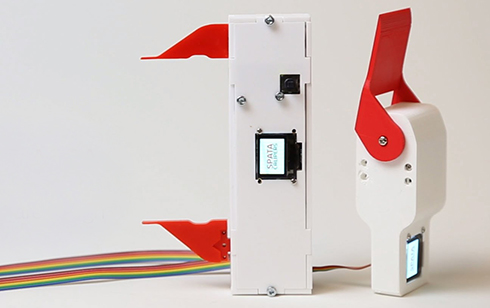

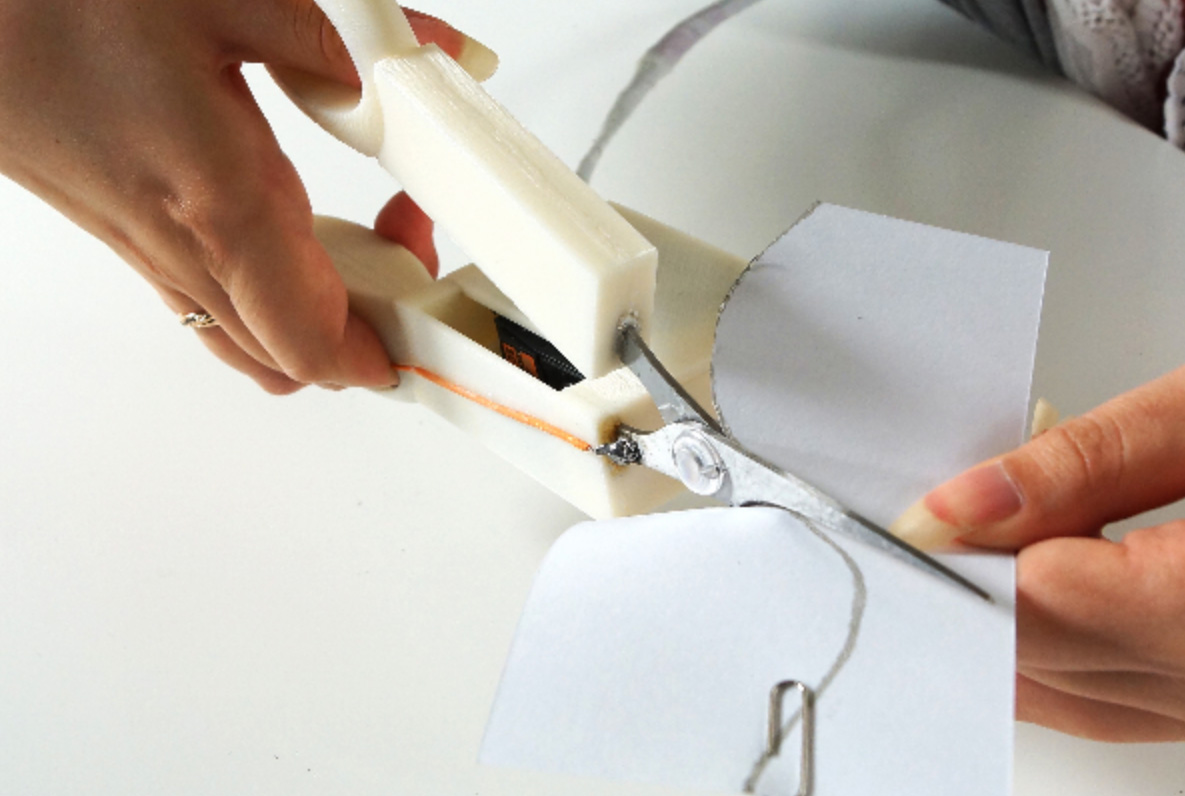

We present Print-A-Sketch, an open-source handheld printer prototype for sketching circuits and sensors. Print-A-Sketch combines desirable properties from free-hand sketching and functional electronic printing. Manual human control of large strokes is augmented with computer control of fine detail. Shared control of Print-A-Sketch supports sketching interactive interfaces on everyday objects – including many objects with materials or sizes which otherwise are difficult to print on. We present an overview of challenges involved in such a system and show how these can be addressed using context-aware, dynamic printing. Continuous sensing ensures quality prints by adjusting inking-rate to hand movement and material properties. Continuous sensing also enables the print to adapt to previously printed traces to support incremental and iterative sketching. Results show good conductivity on many materials and high spatial precision, supporting on-the-fly creation of functional interfaces.

DOI

PDF

Video

Page

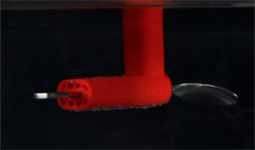

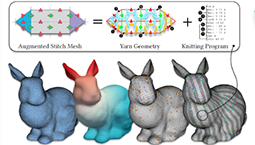

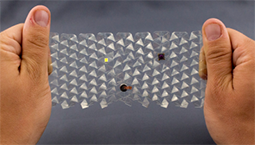

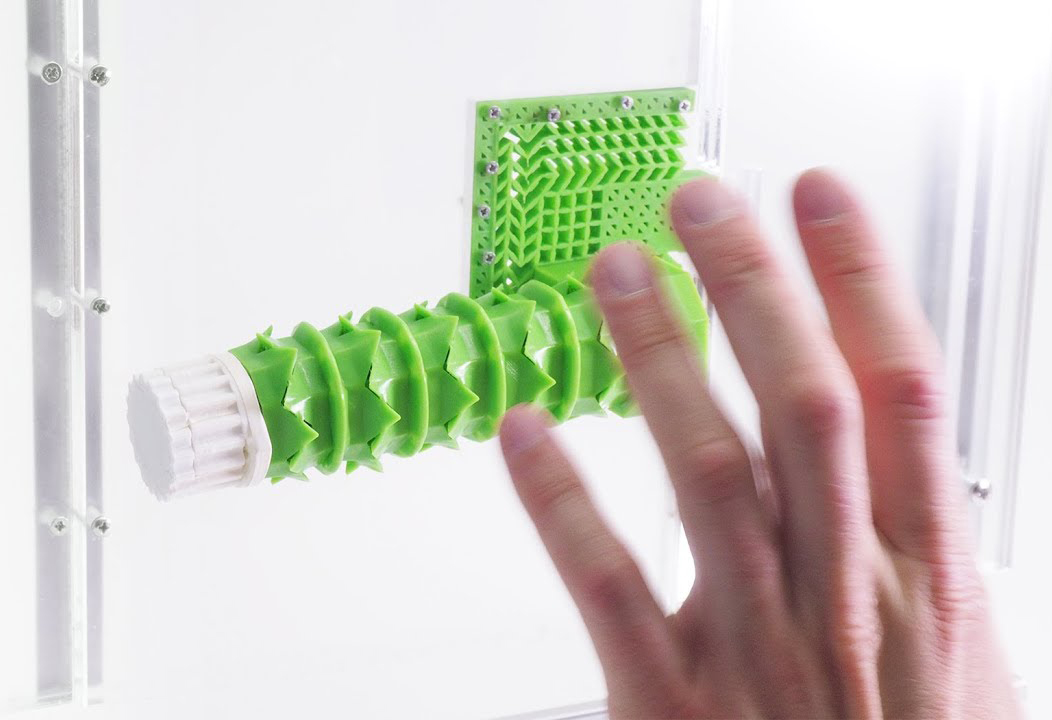

KnitSkin: Machine-Knitted Scaled Skin for Locomotion (ACM CHI 2022)

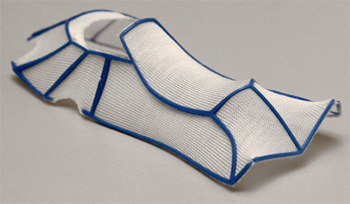

We present KnitSkin, a bio-inspired sleeve that can traverse diverse cylindrical terrains, ranging from a user’s forearm at a wearable scale, to pipes and tree branches at an environmental scale. Fabricated with a machine knitted substrate, the sleeve configures a stepped array of knitted scales that exhibit anisotropic friction. Coupled with the extension of actuators enclosed in the sleeve, the scales enable effective directional locomotion on cylindrical surfaces with varying slopes, textures, and curvatures. KnitSkin’s substrates are characterized by scales whose geometries and materials can be fine-tuned and channels that can accommodate diverse actuators. We introduce the design elements of KnitSkin in which we characterize a series of substrate parameters and their resulting anisotropic behaviors. In evaluating the locomotion, we examine the variables associated with the surface and actuator characteristics. KnitSkin obtains diverse applications across different scales, including wearable interfaces, industrial pipe-monitoring, to agricultural robots.

DOI

PDF

Video

Page

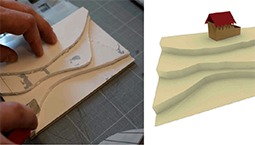

ASTEROIDS: Exploring Swarms of Mini-Telepresence Robots for Physical Skill Demonstration (ACM CHI 2022)

Online synchronous tutoring allows for immediate engagement between instructors and audiences over distance. However, tutoring physical skills remains challenging because current telepresence approaches may not allow for adequate spatial awareness, viewpoint control of the demonstration activities scattered across an entire work area, and the instructor’s sufficient awareness of the audience. We present Asteroids, a novel approach for tangible robotic telepresence, to enable workbench-scale physical embodiments of remote people and tangible interactions by the instructor. With Asteroids, the audience can actively control a swarm of mini-telepresence robots, change camera positions, and switch to other robots’ viewpoints. Demonstrators can perceive the audiences’ physical presence while using tangible manipulations to control the audience’s viewpoints and presentation flow. We conducted an exploratory evaluation for Asteroids with 12 remote participants in a model-making tutorial scenario with an architectural expert demonstrator. Results suggest our unique features benefitted participants’ engagement, sense of presence, and understanding.

DOI

PDF

Video

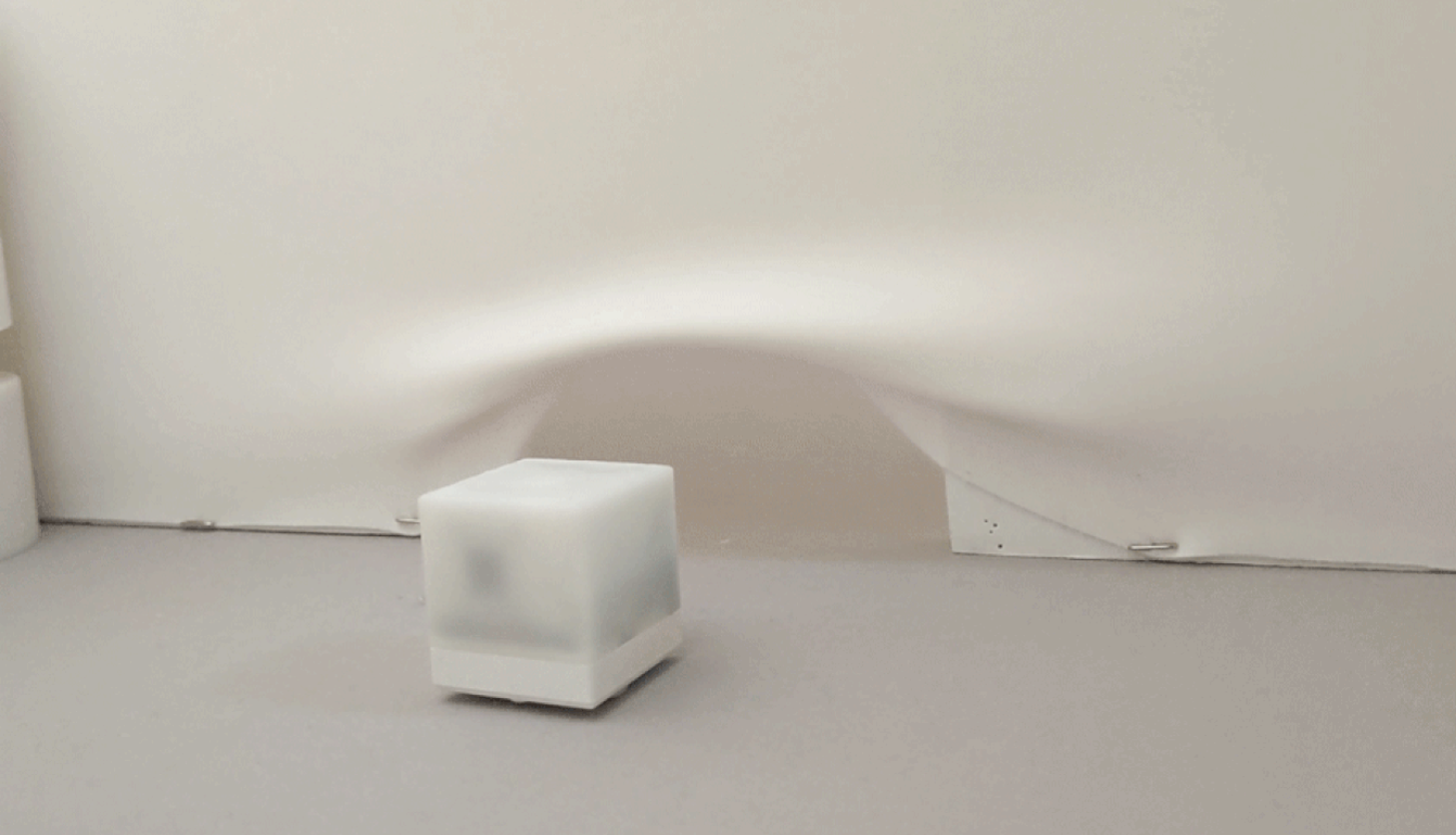

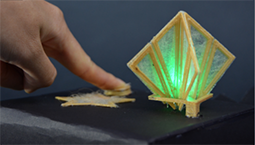

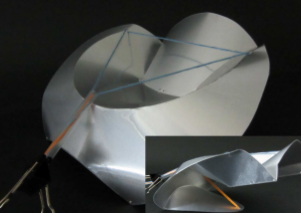

ElectriPop: Low-Cost, Shape-Changing Displays Using Electrostatically Inflated Mylar Sheets (ACM CHI 2022)

We describe how sheets of metalized mylar can be cut and then “inflated” into complex 3D forms with electrostatic charge for use in digitally-controlled, shape-changing displays. This is achieved by placing and nesting various cuts, slits and holes such that mylar elements repel from one another to reach an equilibrium state. Importantly, our technique is compatible with industrial and hobbyist cutting processes, from die and laser cutting to handheld exacto-knives and scissors. Given that mylar film costs <$1 per m2, we can create self-actuating 3D objects for just a few cents, opening new uses in low-cost consumer goods. We describe a design vocabulary, interactive simulation tool, fabrication guide, and proof-of-concept electrostatic actuation hardware. We detail our technique’s performance metrics along with qualitative feedback from a design study. We present numerous examples generated using our pipeline to illustrate the rich creative potential of our method.

DOI

PDF

Video

Page

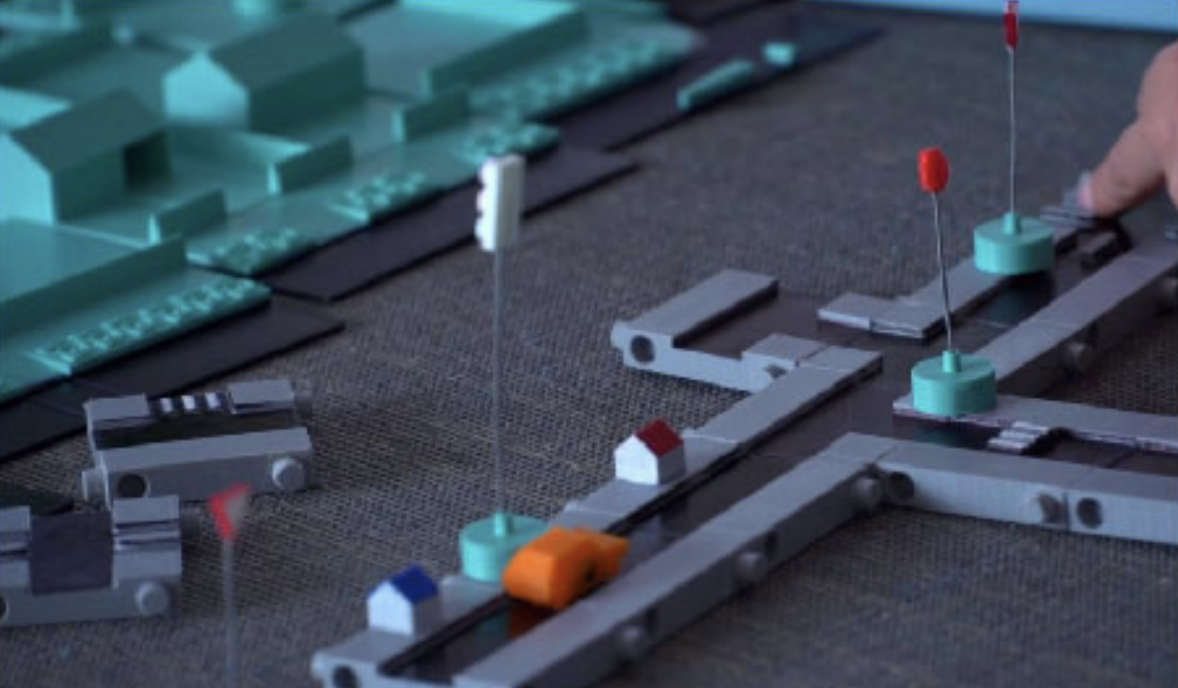

3D Printed Street Crossings: Supporting Orientation and Mobility Training with People who are Blind or have Low Vision (ACM CHI 2022)

The ability to cross the street at intersections is an essential skill, often taught to people who are blind or have low vision (BLV) with the aid of tactile maps and kits or toys. However, each of the existing mapping tools has shortcomings. We investigated whether co-designed 3D printed components can offer benefits. Guided by consultation with 11 Orientation and Mobility (O&M) professionals, we co-designed a series of 3D printed kits that they then used in their practice with BLV children who showed high levels of engagement and learning. The 3D materials were found to demonstrate the key concepts for street crossings in a portable, engaging and professional manner. They will be released for free download, enabling O&M professionals to access or modify the materials as required. We hope that use of our co-designed 3D printed tools will contribute to the safety, independence and inclusion of BLV people.

DOI

PDF

Video

O&O: A DIY toolkit for designing and rapid prototyping olfactory interfaces (ACM CHI 2022)

Constructing olfactory interfaces on demand requires significant design proficiency and engineering effort. The absence of powerful and convenient tools that reduced innovation complexity posed obstacles for future research in the area. To address this problem, we proposed O&O, a modular olfactory interface DIY toolkit. The toolkit consists of: (1) a scent generation kit, a set of electronics and accessories that supported three common scent vaporization techniques; (2) a module construction kit, a set of primitive cardboard modules for assembling permutable functional structures; (3) a design manual, a step-by-step design thinking framework that directs the decision-making and prototyping process. We organized a formal workshop with 19 participants and four solo DIY trials to evaluate the capability of the toolkit, the overall user engagement, the creations in both sessions, and the iterative suggestions. Finally, design implications and future opportunities were discussed for further research.

DOI

PDF

Video

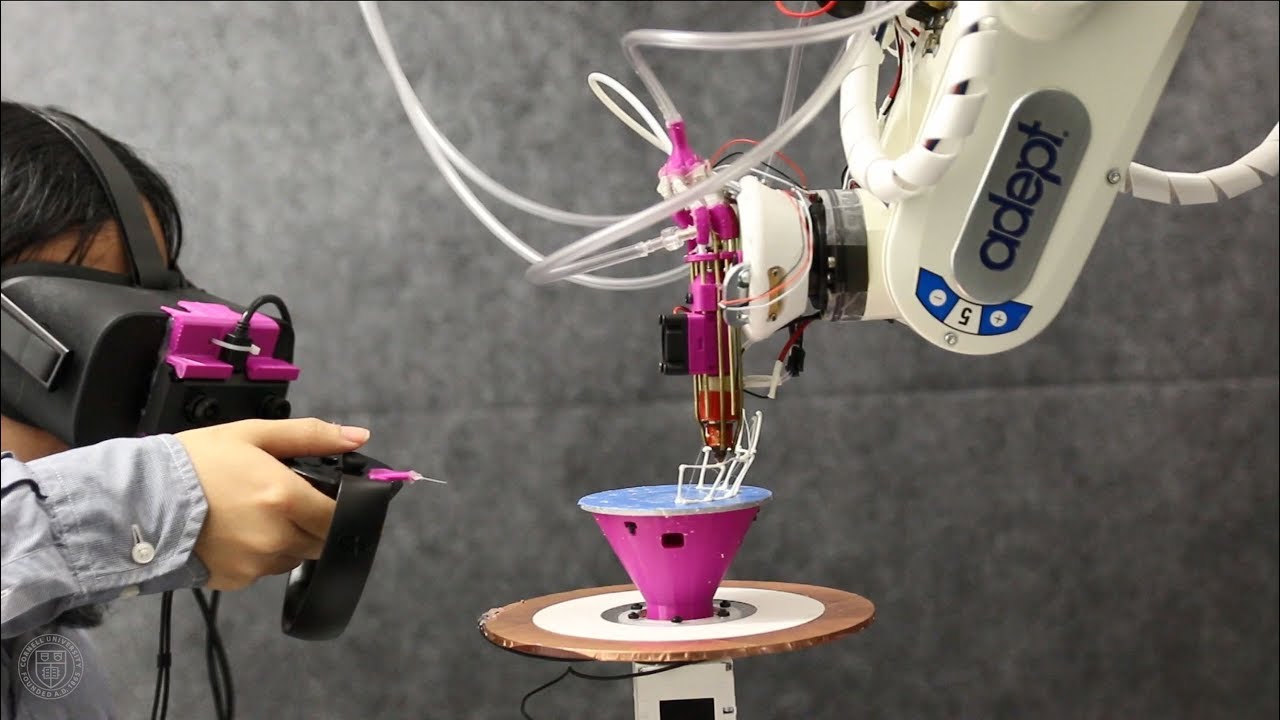

Interactive Robotic Plastering: Augmented Interactive Design and Fabrication for On-site Robotic Plasteri (ACM CHI 2022)

This paper presents Interactive Robotic Plastering (IRoP), a system enabling designers and skilled workers to engage intuitively with an in-situ robotic plastering process. The research combines three elements: interactive design tools, an augmented reality interface, and a robotic spraying system. Plastering is a complex process relying on tacit knowledge and craftsmanship, making it difficult to simulate and automate. However, our system utilizes a controller-based interaction system to enable diverse users to interactively create articulated plasterwork in-situ. A customizable computational toolset converts human intentions into robotic motions while respecting robotic and material constraints. To accomplish this, we developed both an interactive computational model to translate the data from a motion-tracking system into robotic trajectories using design and editing tools as well as an audio-visual guidance system for in-situ projection. We then conducted two user-studies of designers and skilled workers who used IRoP to design and fabricate a full-scale demonstrator.

DOI

PDF

Video

First Steps Towards Designing Electrotactons: Investigating Intensity and Pulse Frequency as Parameters for Electrotactile Cues. (ACM CHI 2022)

Electrotactile stimulation is a novel form of haptic feedback. There is little work investigating its basic design parameters and how they create effective tactile cues. This paper describes two experiments that extend our knowledge of two key parameters. The first investigated the combination of pulse width and amplitude (Intensity) on sensations of urgency, annoyance, valence and arousal. Results showed significant effects: increasing Intensity caused higher ratings of urgency, annoyance and arousal but reduced valence. We established clear levels for differentiating each sensation. A second study then investigated Intensity and Pulse Frequency to find out how many distinguishable levels could be perceived. Results showed that both Intensity and Pulse Frequency significantly affected perception, with four distinguishable levels of Intensity and two of Pulse Frequency. These results add significant new knowledge about the parameter space of electrotactile cue design and help designers select suitable properties to use when creating electrotactile cues.

DOI

PDF

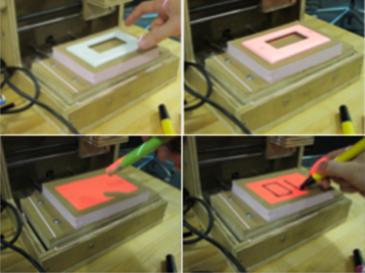

FabricatINK: Personal Fabrication of Bespoke Displays Using Electronic Ink from Upcycled E Readers (ACM CHI 2022)

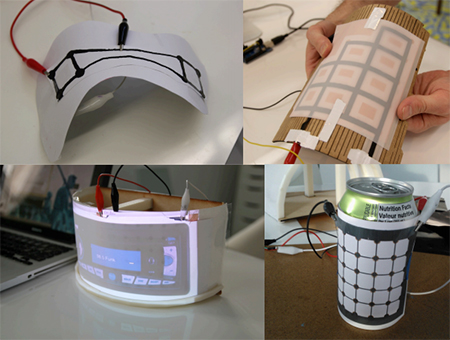

Abstract: FabricatINK explores the personal fabrication of irregularly-shaped low-power displays using electronic ink (E ink). E ink is a programmable bicolour material used in traditional form-factors such as E readers. It has potential for more versatile use within the scope of personal fabrication of custom-shaped displays, and it has the promise to be the pre-eminent material choice for this purpose. We appraise technical literature to identify properties of E ink, suited to fabrication. We identify a key roadblock, universal access to E ink as a material, and we deliver a method to circumvent this by upcycling broken electronics. We subsequently present a novel fabrication method for irregularly-shaped E ink displays. We demonstrate our fabrication process and E ink’s versatility through ten prototypes showing different applications and use cases. By addressing E ink as a material for display fabrication, we uncover the potential for users to create custom-shaped truly bistable displays.

DOI

PDF

Video

2021

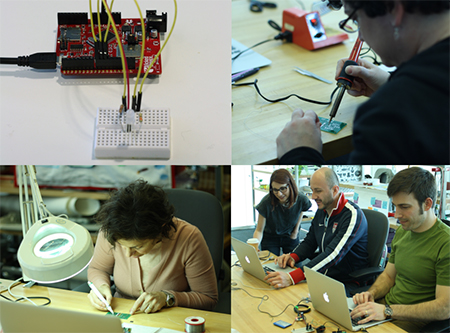

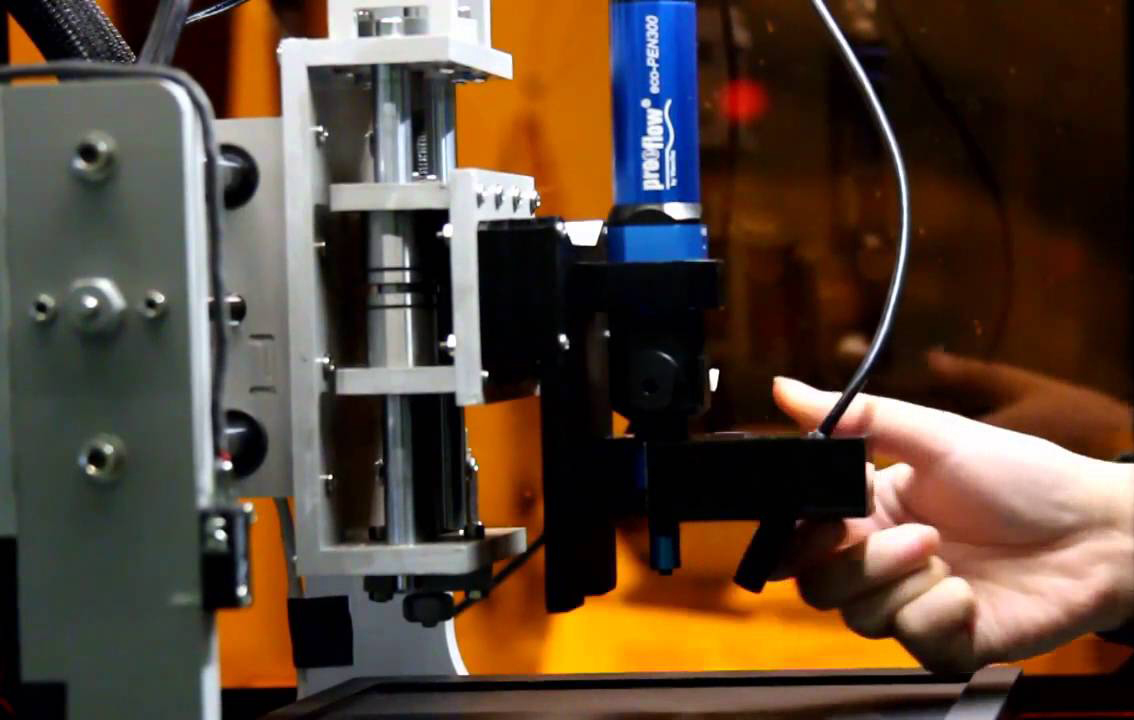

Adroid: Augmenting Hands-on Making with a Collaborative Robot (ACM UIST 2021)

Adroid1 enables users to borrow precision and accuracy from a robotic arm when using hand-held tools. When a tool is mounted to the robot, the user can hold and move the tool directly—Adroid measures the user’s applied forces and commands the robot to move in response. Depending on the tool and scenario, Adroid can selectively restrict certain motions. In the resulting interaction, the robot acts like a virtual “jig” which constrains the tool’s motion, augmenting the user’s accuracy, technique, and strength, while not diminishing their agency during open-ended fabrication tasks. We complement these hands-on interactions with projected augmented reality for visual feedback about the state of the system. We show how tools augmented by Adroid can support hands-on making and discuss how it can be configured to support other tasks within and beyond fabrication.

DOI

PDF

Video

Page

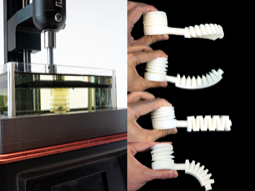

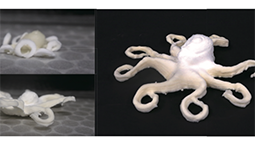

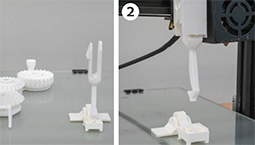

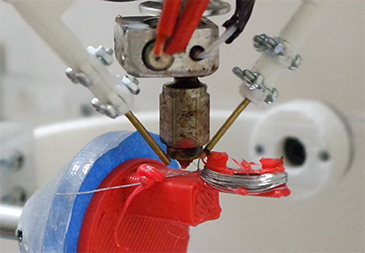

FabHydro: Printing Interactive Hydraulic Devices with an Affordable SLA 3D Printer (ACM UIST 2021)

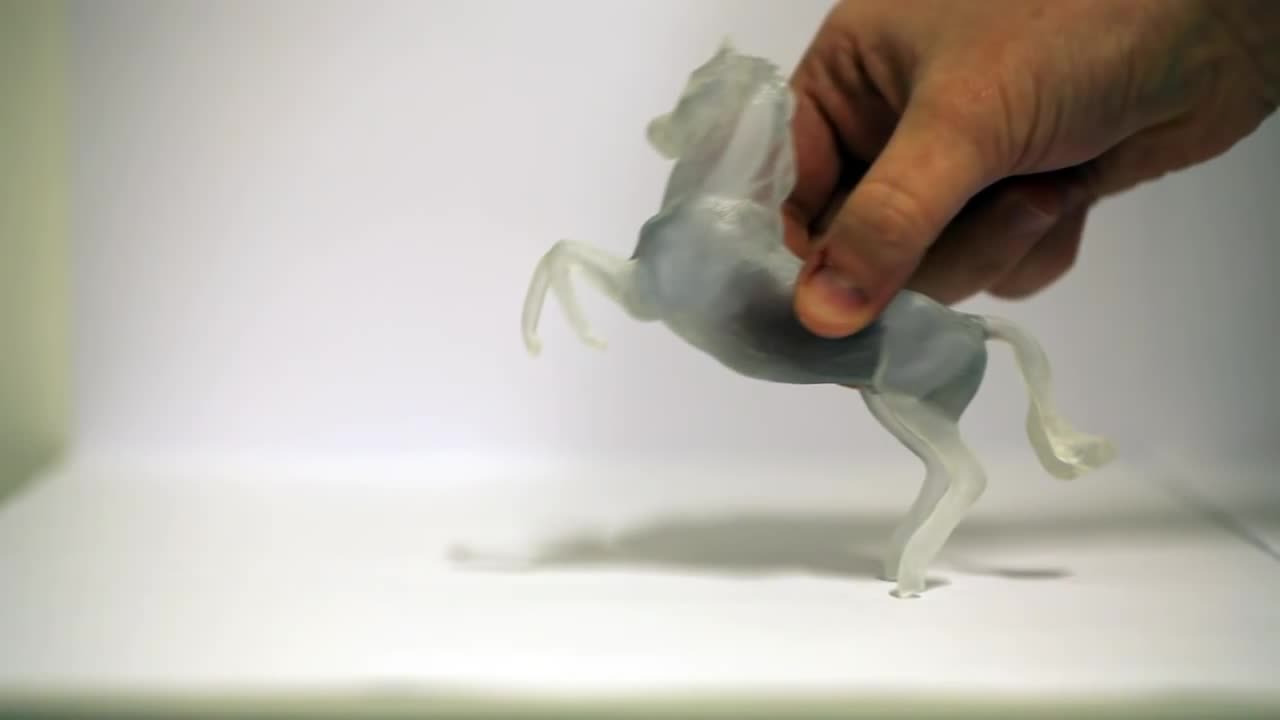

We introduce FabHydro, a set of rapid and low-cost methods to prototype interactive hydraulic devices based on an off-the-shelf 3D printer and flexible photosensitive resin. We first present printer settings and custom support structures to warrant the successful print of flexible and deformable objects. We then demonstrate two printing methods to seal the transmission fluid inside these deformable structures: the Submerged Printing process that seals the liquid resin without manual assembly, and the Printing with Plugs method that allows the use of different transmission fluids without modification to the printer. Following the printing methods, we report a design space with a range of 3D printable primitives, including the hydraulic generator, transmitter, and actuator. To demonstrate the feasibility of our approaches and the breadth of new designs that they enable, we showcase a set of examples from a printed robotic gripper that can be operated at a distance to a mobile phone stand that serves as a status reminder by repositioning the user’s phone. We conclude with a discussion of our approach’s limitations and possible future improvements.

DOI

PDF

Video

Page

Daedalus in the Dark: Designing for Non-Visual Accessible Construction of Laser-Cut Architecture (ACM UIST 2021)

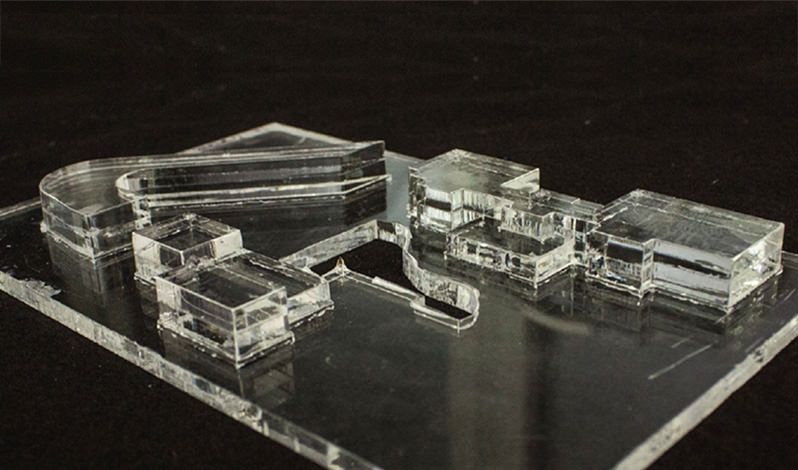

Design tools and research regarding laser-cut architectures have been widely explored in the past decade. However, such discussion has mostly revolved around technical and structural design questions instead of another essential element of laser-cut models — assembly — a process that relies heavily on components’ visual affordance, therefore less accessible to blind or low vision (BLV) people. To narrow the gap in this area, we co-designed with 7 BLV people to examine their assembly experience with different laser-cut architectures. From their feedback, we proposed several design heuristics and guidelines for Daedalus, a generative design tool that can produce tactile aids for laser-cut assembly given a few high-level manual inputs. We validate the proposed aids in a user study with 8 new BLV participants. Our results revealed that BLV users can manage laser-cut assembly more efficiently with Daedalus. Going forth from this design iteration, we discuss implications for future research on accessible laser-cut assembly.

DOI

PDF

Video

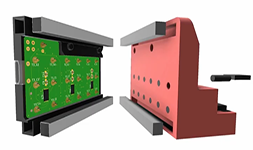

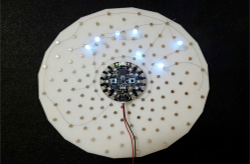

EIT-kit: An Electrical Impedance Tomography Toolkit for Health and Motion Sensing (ACM UIST 2021)

In this paper, we propose EIT-kit, an electrical impedance tomography toolkit for designing and fabricating health and motion sensing devices. EIT-kit contains (1) an extension to a 3D editor for personalizing the form factor of electrode arrays and electrode distribution, (2) a customized EIT sensing motherboard for performing the measurements, (3) a microcontroller library that automates signal calibration and facilitates data collection, and (4) an image reconstruction library for mobile devices for interpolating and visualizing the measured data. Together, these EIT-kit components allow for applications that require 2- or 4-terminal setups, up to 64 electrodes, and single or multiple (up to four) electrode arrays simultaneously. We motivate the design of each component of EIT-kit with a formative study, and conduct a technical evaluation of the data fidelity of our EIT measurements. We demonstrate the design space that EIT-kit enables by showing various applications in health as well as motion sensing and control.

DOI

PDF

Video

Page

PneuSeries: 3D Shape Forming with Modularized Serial-Connected Inflatables (ACM UIST 2021)

We present PneuSeries, a series of modularized inflatables where their inflation and deflation are propagated in-between stage by stage to form various shapes. The key component of PneuSeries is the bidirectional check valve that passively regulates the air flowing in/out from/to adjacent inflatables, allowing each of the inflatables to be inflated/deflated one by one through serial propagation. The form of the inflatable series thus is programmed by the sequential operations of a pump that push/pull the air in/out. In this paper, we explored the design of PneuSeries and implemented working prototypes as a proof of concept. In particular, we built PneuSeries with (1) modularized cubical, cuboidal, tetrahedral, prismatic, and custom inflatables to examine their shape forming, (2) fast assembly connectors to allow quick reconfiguration of the series, and (3) folding mechanism to reduce irregularity of the shrunken inflatables. We also evaluated the inflating and deflating time and the flow rate of the valve for simulating the inflating and deflating process and display the steps and time required to transform in our software. Finally, we demonstrate example objects that show the capability of PneuSeries and its potential applications.

DOI

PDF

Video

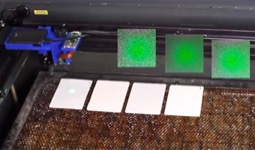

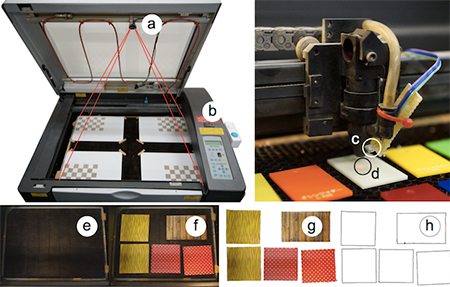

SensiCut: Material-Aware Laser Cutting Using Speckle Sensing and Deep Learning (ACM UIST 2021)

Laser cutter users face difficulties distinguishing between visually similar materials. This can lead to problems, such as using the wrong power/speed settings or accidentally cutting hazardous materials. To support users, we present SensiCut, an integrated material sensing platform for laser cutters. SensiCut enables material awareness beyond what users are able to see and reliably differentiates among similar-looking types. It achieves this by detecting materials’ surface structures using speckle sensing and deep learning. SensiCut consists of a compact hardware add-on for laser cutters and a user interface that integrates material sensing into the laser cutting workflow. In addition to improving the traditional workflow and its safety1, SensiCut enables new applications, such as automatically partitioning designs when engraving on multi-material objects or adjusting their geometry based on the kerf of the identified material. We evaluate SensiCut’s accuracy for different types of materials under different sheet orientations and illumination conditions.

DOI

PDF

Video

Page

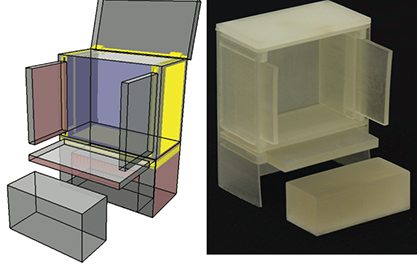

autoAssembler: Automatic Reconstruction of Laser-Cut 3D Models (ACM UIST 2021)

Recent research showed how to import laser cut 3D models encoded in the form of 2D cutting plans into a 3D editor (assembler3), which allows users to perform parametric manipulations on such models. In contrast to assembler3 , which requires users to perform this process manually, we present autoAssembler, which performs this process automatically. AutoAssembler uses a beam search algorithm to search possible ways of assembling plates. It uses joints on these plates to combine them into assembly candidates. It thereby preferably pursues candidates (1) that have no intersecting plates, (2) that fit into a small bounding box, (3) that use plates whose joints fit together well, (4) that do not add many unpaired joints, (5) that make use of constraints posed by other plates, and (6) that conform to symmetry axes of the plates. This works for models that have at least one edge joint (finger or t-joint). In our technical evaluation, we imported 66 models using autoAssembler. AutoAssembler assembled 79% of those models fully automatically; another 18% of models required on average 2.7 clicks of post-processing, for an overall success rate of 97%.

DOI

PDF

Video

Page

Taxon: a Language for Formal Reasoning with Digital Fabrication Machines (ACM UIST 2021)

Digital fabrication machines for makers have expanded access to manufacturing processes such as 3D printing, laser cutting, and milling. While digital models encode the data necessary for a machine to manufacture an object, understanding the trade-offs and limitations of the machines themselves is crucial for successful production. Yet, this knowledge is not codified and must be gained through experience, which limits both adoption of and creative exploration with digital fabrication tools. To formally represent machines, we present Taxon, a language that encodes a machine’s high-level characteristics, physical composition, and performable actions. With this programmatic foundation, makers can develop rules of thumb that filter for appropriate machines for a given job and verify that actions are feasible and safe. We integrate the language with a browser-based system for simulating and experimenting with machine workflows. The system lets makers engage with rules of thumb and enrich their understanding of machines. We evaluate Taxon by representing several machines from both common practice and digital fabrication research. We find that while Taxon does not exhaustively describe all machines, it provides a starting point for makers and HCI researchers to develop tools for reasoning about and making decisions with machines.

DOI

PDF

Video

Page

Roadkill: Nesting Laser-Cut Objects for Fast Assembly (ACM UIST 2021)

We present Roadkill, a software tool that converts 3D models to 2D cutting plans for laser cutting—such that the resulting layouts allow for fast assembly. Roadkill achieves this by putting all relevant information into the cutting plan: (1) Thumbnails indicate which area of the model a set of parts belongs to. (2) Parts with exposed finger joints are easy to access, thereby suggesting to start assembly here. (3) Openings in the sheet act as jigs, affording assembly within the sheet. (4) Users continue assembly by inserting what has already been assembled into parts that are immediately adjacent or are pointed to by arrows. Roadkill maximizes the number of joints rendered in immediate adjacency by breaking down models into “subassemblies.” Within a subassembly, Roadkill holds the parts together using break-away tabs. (5) Users complete subassemblies according to their labels 1, 2, 3…, following 1 -> 1 links to insert subassemblies into other subassemblies, until all parts come together. In our user study, Roadkill allowed participants to assemble layouts 2.4 times faster than layouts generated by a traditional pair-wise labeling of plates.

DOI

PDF

Video

Page

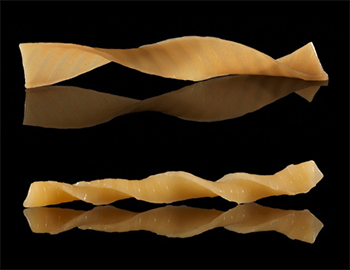

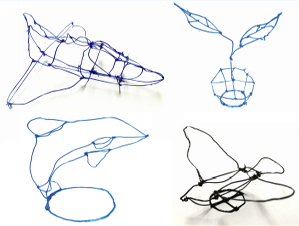

OmniFiber: Integrated Fluidic Fiber Actuators for Weaving Movement based Interactions into the ‘Fabric of Everyday Life’ (ACM UIST 2021)

Fiber – a primitive yet ubiquitous form of material – intertwines with our bodies and surroundings, from constructing our fibrous muscles that enable our movement, to forming fabrics that intimately interface with our skin. In soft robotics and advanced materials science research, actuated fibers are gaining interest as thin, flexible materials that can morph in response to external stimuli. In this paper, we build on fluidic artificial muscles research to develop OmniFiber - a soft, line-based material system for designing movement-based interactions. We devised actuated thin (øouter < 1.8 mm) fluidic fibers with integrated soft sensors that exhibit perceivably strong forces, up to 19 N at 0.5 MPa, and a high speed of linear actuation peaking at 150mm/s. These allow to flexibly weave them into everyday tangible interactions; including on-body haptic devices for embodied learning, synchronized tangible interfaces for remote communication, and robotic crafting for expressivity. The design of such interactive capabilities is supported by OmniFiber’s design space, accessible fabrication pipeline, and a fluidic I/O control system to bring omni-functional fluidic fibers to the HCI toolbox of interactive morphing materials.

DOI

PDF

Video

Page

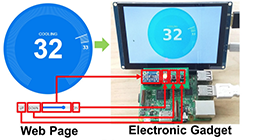

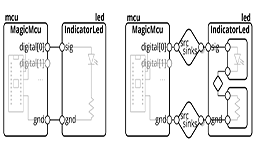

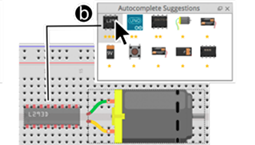

Weaving Schematics and Code: Interactive Visual Editing for Hardware Description Languages (ACM UIST 2021)

In many engineering disciplines such as circuit board, chip, and mechanical design, a hardware description language (HDL) approach provides important benefits over direct manipulation interfaces by supporting concepts like abstraction and generator meta-programming. While several such HDLs have emerged recently and promised power and flexibility, they also present challenges – especially to designers familiar with current graphical workflows. In this work, we investigate an IDE approach to provide a graphical editor for a board-level circuit design HDL. Unlike GUI builders which convert an entire diagram to code, we instead propose generating equivalent HDL from individual graphical edit actions. By keeping code as the primary design input, we preserve the full power of the underlying HDL, while remaining useful even to advanced users. We discuss our concept, design considerations such as performance, system implementation, and report on the results of an exploratory remote user study with four experienced hardware designers.

DOI

PDF

Video

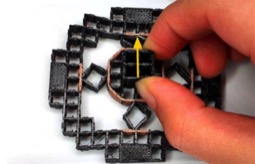

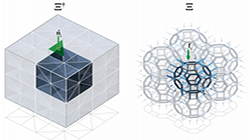

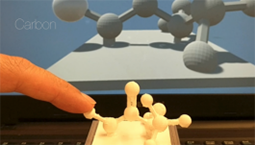

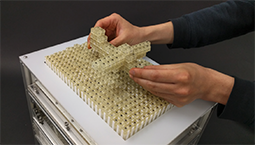

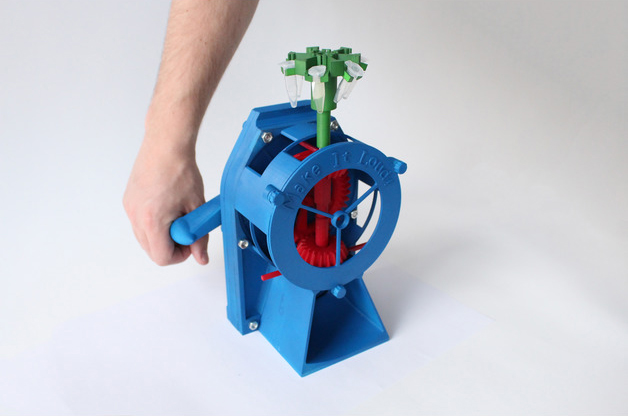

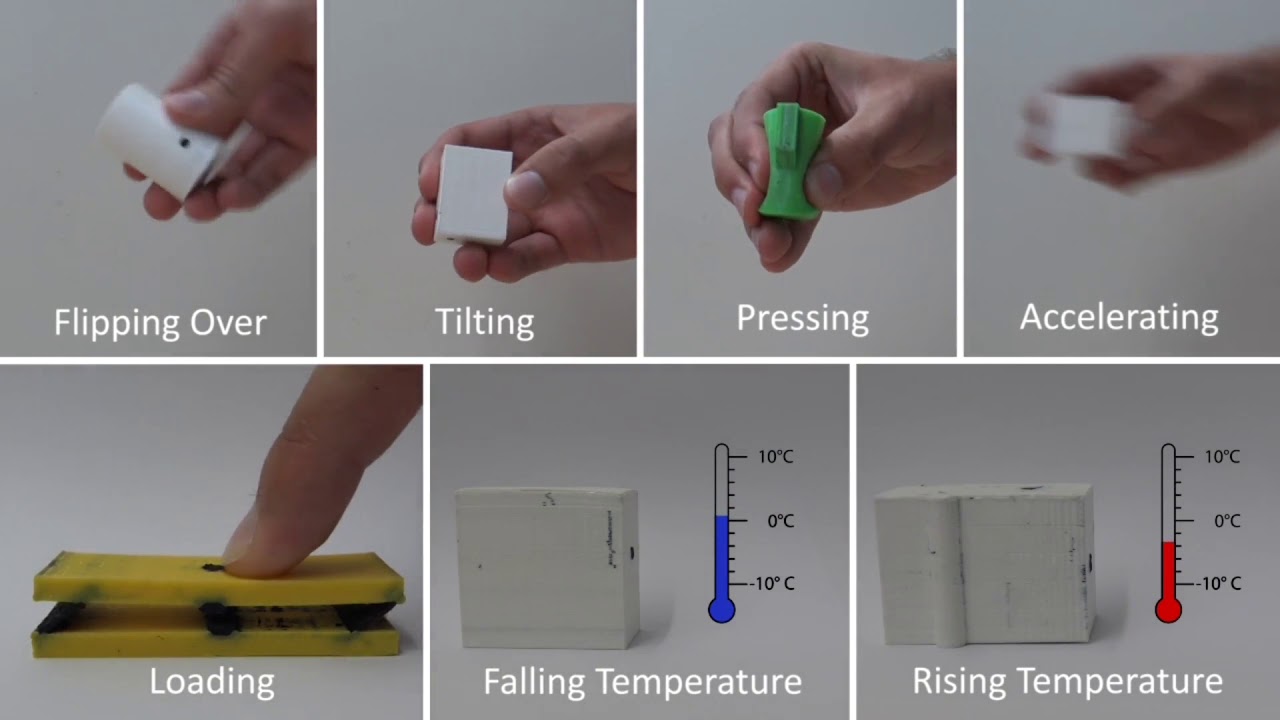

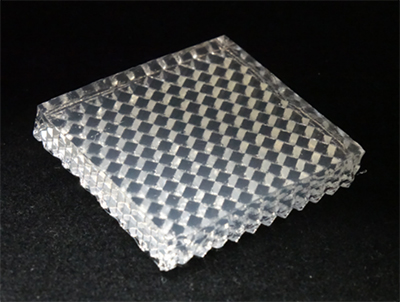

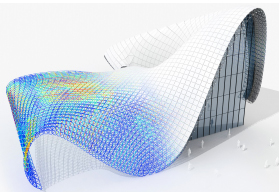

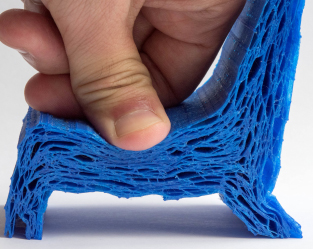

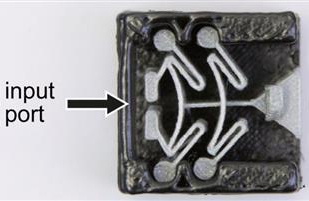

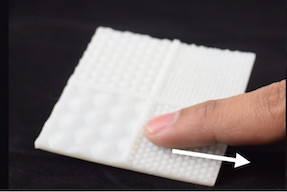

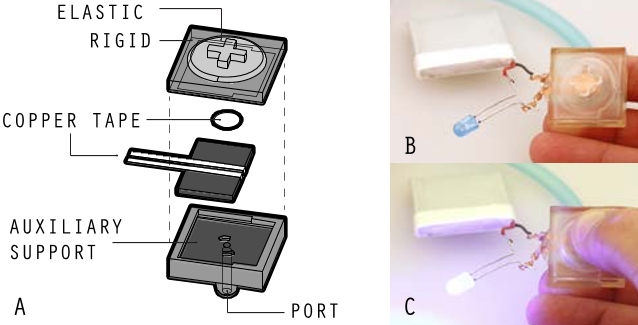

MetaSense: Integrating Sensing Capabilities into Mechanical Metamaterial (ACM UIST 2021)

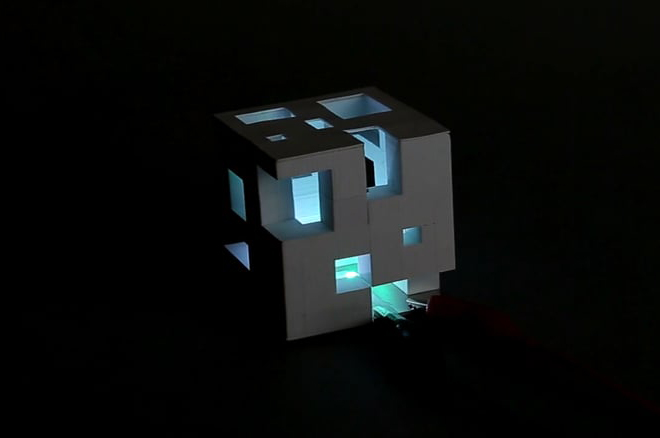

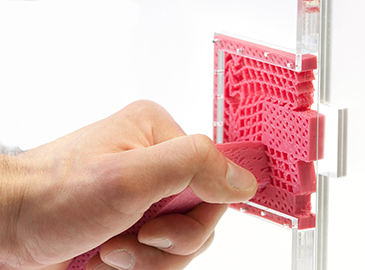

In this paper, we present a method to integrate sensing capabilities into 3D printable metamaterial structures comprised of cells, which enables the creation of monolithic input devices for HCI. We accomplish this by converting select opposing cell walls within the metamaterial device into electrodes, thereby creating capacitive sensors. When a user interacts with the object and applies a force, the distance and overlapping area between opposing cell walls change, resulting in a measurable capacitance variation.

To help designers create interactive metamaterial devices, we contribute a design and fabrication pipeline based on multi-material 3D printing. Our 3D editor automatically places conductive cells in locations that are most affected by deformation during interaction and thus are most suitable as sensors. On export, our editor creates two files, one for conductive and one for non-conductive cell walls, which designers can fabricate on a multi-material 3D printer. Our applications show that designers can create metamaterial devices that sense various interactions, including sensing acceleration, binary state, shear, and magnitude and direction of applied force.

DOI

PDF

Video

Page

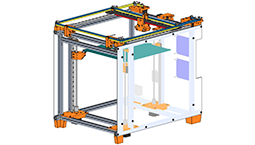

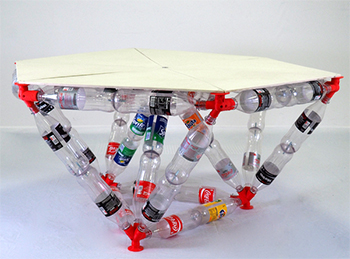

Trusscillator: a System for Fabricating Human-Scale Human-Powered Oscillating Devices

Trusscillator is an end-to-end system that allows non-engineers to create human-scale human-powered devices that perform oscillatory movements, such as playground equipment, workout devices, and interactive kinetic installations. While recent research has been focusing on generating mechanisms that produce specific movement-path, without considering the required energy for the motion (kinematic approach), Trusscillator supports users in designing mechanisms that recycle energy in the system in the form of oscillating mechanisms (dynamic approach), specifically with the help of coil-springs. The presented system features a novel set of tools tailored for designing the dynamic experience of the motion. These tools allow designers to focus on user experience-specific aspects, such as motion range, tempo, and effort while abstracting away the underlying technicalities of eigenfrequencies, spring constants, and energy. Since the forces involved in the resulting devices can be high, Trusscillator helps users to fabricate from steel by picking out appropriate steal springs, generating part lists, and producing stencils and welding jigs that help weld with precision. To validate our system, we designed, built, and tested a series of unique playground equipment featuring 2-4 degrees of movement.

DOI

PDF

Video

Page

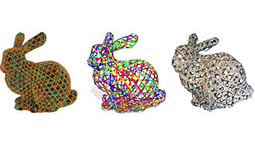

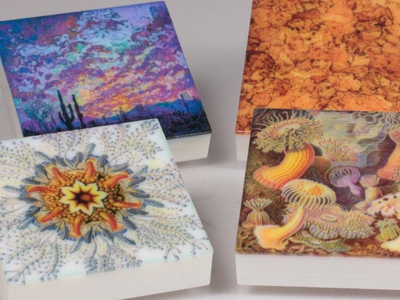

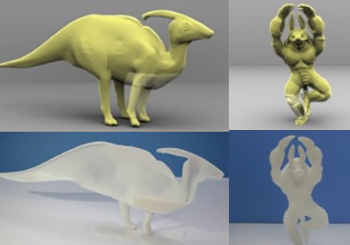

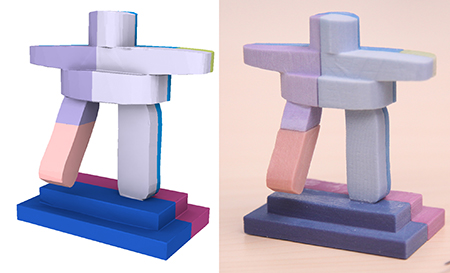

Lenticular Objects: 3D Printed Objects with Lenticular Lens Surfaces That Can Change their Appearance Depending on the Viewpoint

In this paper, we present a method that makes 3D objects appear differently under different viewpoints. We accomplish this by 3D printing lenticular lenses across the curved surface of objects. By calculating the lens distribution and the corresponding surface color patterns, we can determine which appearance is shown to the user at each viewpoint. We built a 3D editor that takes as input the 3D model, and the visual appearances, i.e. images, to show at different viewpoints. Our 3D editor then calculates the corresponding lens placements and underlying color pattern. On export, the user can use ray tracing to live preview the resulting appearance from each angle. The 3D model, color pattern, and lenses are then 3D printed in one pass on a multi-material 3D printer to create the final 3D object. To determine the best fabrication parameters for 3D printing lenses, we printed lenses of different sizes and tested various post-processing techniques. To support a large number of different appearances, we compute the lens geometry that has the best trade-off between the number of viewpoints and the protrusion from the object geometry. Finally, we demonstrate our system in practice with a range of use cases for which we show the simulated and physical results side by side.

DOI

PDF

Video

Page

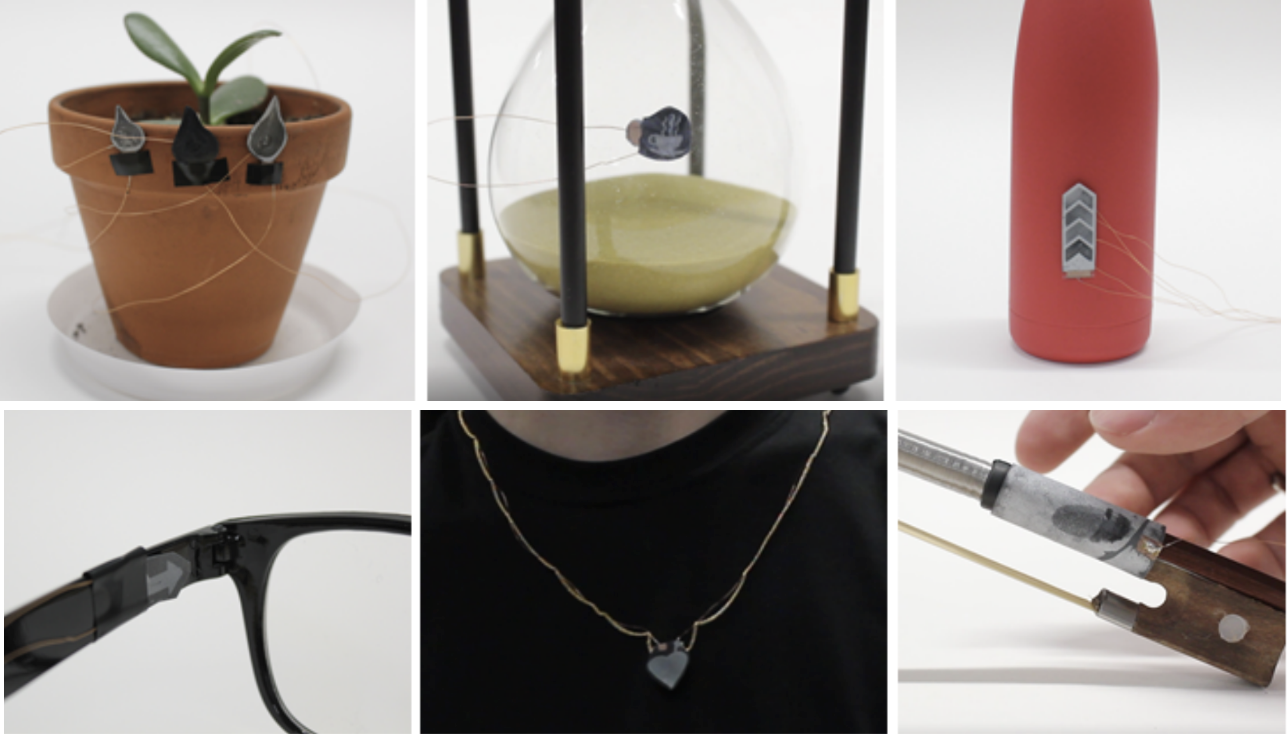

MARS: Nano-Power Battery-free Wireless Interfaces for Touch, Swipe and Speech Input

Augmenting everyday surfaces with interaction sensing capability that is maintenance-free, low-cost (∼ $1), and in an appropriate form factor is a challenge with current technologies. MARS (Multi-channel Ambiently-powered Realtime Sensing) enables battery-free sensing and wireless communication of touch, swipe, and speech interactions by combining a nanowatt programmable oscillator with frequency-shifted analog backscatter communication. A zero-threshold voltage field-effect transistor (FET) is used to create an oscillator with a low startup voltage (∼ 500 mV) and current (< 2uA), whose frequency can be affected through changes in inductance or capacitance from the user interactions. Multiple MARS systems can operate in the same environment by tuning each oscillator circuit to a different frequency range. The nanowatt power budget allows the system to be powered directly through ambient energy sources like photodiodes or thermoelectric generators. We differentiate MARS from previous systems based on power requirements, cost, and part count and explore different interaction and activity sensing scenarios suitable for indoor environments.

DOI

PDF

Video

Page

PocketView: Through-Fabric Information Displays

People often have to remove their phone from an inaccessible location like a pocket to view things like notifications and directions. We explore the idea of viewing such information through the fabric of a pocket using low resolution bright LED matrix displays. A survey confirms viewing information on inaccessible phones is desirable, and establishes types of pockets in garments worn by respondents and what objects are typically put in pockets. A technical evaluation validates that LED light can shine through many common garment fabrics. Based on these results, functional hardware prototypes are constructed to demonstrate different form factors of through-fabric display devices, such as a phone, wallet, a key fob, a pen, and earbud headphone case. A simple interaction vocabulary for viewing key information on these devices is described, and the social and technical aspects of the approach are discussed.

DOI

PDF

Video

Page

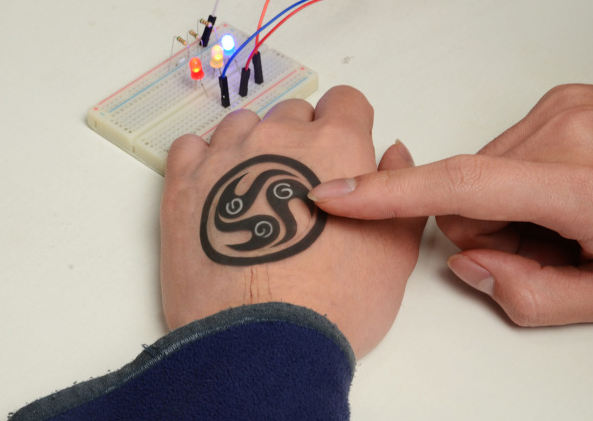

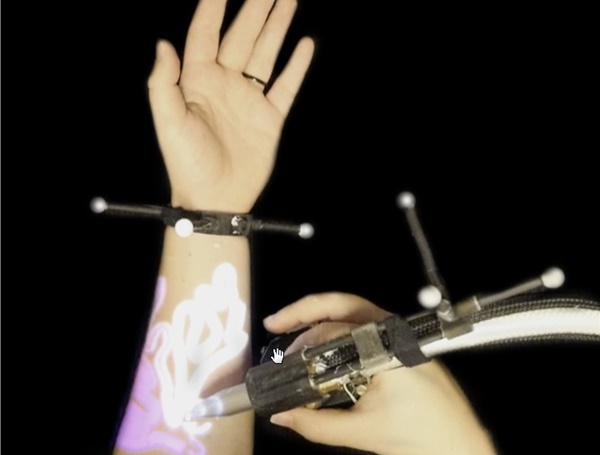

BodyStylus: Freehand On-Body Design and Fabrication of Epidermal Interfaces (ACM CHI 2021)

In traditional body-art, designs are adjusted to the body as they are applied, enabling creative improvisation and exploration. Conventional design and fabrication methods of epidermal interfaces, however, separate these steps. With BodyStylus we present the first computer-assisted approach for on-body design and fabrication of epidermal interfaces. Inspired by traditional techniques, we propose a hand-held tool that augments freehand inking with digital support: projected in-situ guidance assists creating valid on-body circuits and aesthetic ornaments that align with the human bodyscape, while pro-active switching between inking and non-inking creates error preventing constraints. We contribute BodyStylus’s design rationale and interaction concept along with an interactive prototype that uses self-sintering conductive ink. Results of two focus group explorations showed that guidance was more appreciated by artists, while constraints appeared more useful to engineers, and that working on the body inspired critical reflection on the relationship between bodyscape, interaction, and designs.

DOI

PDF

Video

Page

CapContact: Reconstructing High-Resolution Contact Areas on Capacitive Sensors (ACM CHI 2021)

Touch input is dominantly detected using mutual-capacitance sensing, which measures the proximity of close-by objects that change the electric field between the sensor lines. The exponential drop-off in intensities with growing distance enables software to detect touch events, but does not reveal true contact areas. In this paper, we introduce CapContact, a novel method to precisely infer the contact area between the user’s finger and the surface from a single capacitive image. At 8 × super-resolution, our convolutional neural network generates refined touch masks from 16-bit capacitive images as input, which can even discriminate adjacent touches that are not distinguishable with existing methods. We trained and evaluated our method using supervised learning on data from 10 participants who performed touch gestures. Our capture apparatus integrates optical touch sensing to obtain ground-truth contact through high-resolution frustrated total internal reflection. We compare our method with a baseline using bicubic upsampling as well as the ground truth from FTIR images. We separately evaluate our method’s performance in discriminating adjacent touches. CapContact successfully separated closely adjacent touch contacts in 494 of 570 cases (87%) compared to the baseline’s 43 of 570 cases (8%). Importantly, we demonstrate that our method accurately performs even at half of the sensing resolution at twice the grid-line pitch across the same surface area, challenging the current industry-wide standard of a ∼ 4 mm sensing pitch. We conclude this paper with implications for capacitive touch sensing in general and for touch-input accuracy in particular.

DOI

PDF

Video

Page

MagnetIO: Passive yet Interactive Soft Haptic Patches Anywhere (ACM CHI 2021)

We propose a new type of haptic actuator, which we call MagnetIO, that is comprised of two parts: one battery-powered voice-coil worn on the user's fingernail and any number of interactive soft patches that can be attached onto any surface (everyday objects, user's body, appliances, etc.). When the user's finger wearing our voice-coil contacts any of the interactive patches it detects its magnetic signature via magnetometer and vibrates the patch, adding haptic feedback to otherwise input-only interactions. To allow these passive patches to vibrate, we make them from silicone with regions doped with polarized neodymium powder, resulting in soft and stretchable magnets. This stretchable form-factor allows them to be wrapped to the user's body or everyday objects of various shapes. We demonstrate how these add haptic output to many situations, such as adding haptic buttons to the walls of one's home. In our technical evaluation, we demonstrate that our interactive patches can be excited across a wide range of frequencies (0-500 Hz) and can be tuned to resonate at specific frequencies based on the patch's geometry. Furthermore, we demonstrate that MagnetIO's vibration intensity is as powerful as a typical linear resonant actuator (LRA); yet, unlike these rigid actuators, our passive patches operate as springs with multiple modes of vibration, which enables a wider band around its resonant frequency than an equivalent LRA.

DOI

PDF

Video

Documented: Embedding Information onto and Retrieving Information from 3D Printed Objects (ACM CHI 2021)

Documentation for DIY tasks serve as codified project knowledge and help makers reach new understandings and appreciations for the artifact. Engaging in reflective processes using the documentation can be challenging when it comes to physical objects as the documentation and the artifact exist separately. We hypothesize that spatially associating the documentation information with the artifact can provide richer contextualization to reflect upon the artifact and design process. We implemented and evaluated Documented, a web application that helps makers associate documentation to 3D printed objects. Information can be embedded using printed tags spatially placed on the model and accessed using mobile AR. Our study highlights the different strategies participants had for organizing, embedding, and retrieving information. Informed by our results, we discuss how the coupling of the documentation and the artifact can support reflection and identify potential barriers that need further investigation.

DOI

PDF

Video

Page

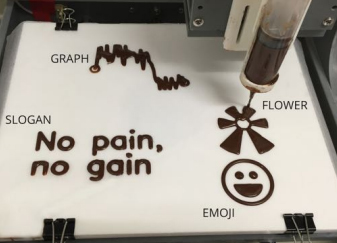

Flower Jelly Printer: Slit Injection Printing for Parametrically Designed Flower Jelly (ACM CHI 2021)

Flower jellies, a delicate dessert in which a flower-shaped jelly floats inside another clear jelly, fascinate people with both their beauty and elaborate construction. In efforts to simplify the challenging fabrication and enrich the design space of this dessert, we present Flower Jelly Printer: a printing device and design software for digitally fabricating flower jellies. Our design software lets users play with parameters and preview the resulting forms until achieving their desired shapes. We also developed slit injection printing that directly injects colored jelly into a base jelly, and shared several design examples to show the breadth of design possibilities. Finally, the user study with novice and experienced users demonstrates that our system benefits creators of all experience levels by iterative design and precise fabrication. We hope to enable more people to design and create their own flower jellies while expanding access and the design space for digitally fabricated foods.

DOI

PDF

Video

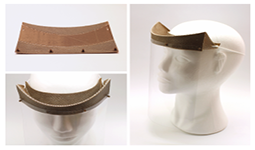

Medical Maker Response to COVID-19: Distributed Manufacturing Infrastructure for Stop Gap Protective Equipment (ACM CHI 2021)

Unprecedented maker efforts arose in response to COVID-19 medical supply gaps worldwide. Makers in the U.S., participated in peer-production activities to manufacture personal protective equipment (PPE). Whereas, medical makers, who innovate exclusively for points of care, pivoted towards safer, reliable PPE. What were their efforts to pivot medical maker infrastructure towards reliable production of safe equipment at higher volumes? We interviewed 13 medical makers as links between institutions, maker communities, and wider regional industry networks. These medical makers organized stopgap manufacturing in institutional spaces to resolve acute shortages (March–May) and chronic shortages (May–July). They act as intermediaries in efforts to prototype and produce devices under regulatory, material, and human constraints of a pandemic. We re-frame their making efforts as repair work to offer an alternate critical view of optimism around making for crisis. We contribute an understanding of these efforts to inform infrastructure design for making with purpose and safety leading to opportunities for community production of safe devices at scale.

DOI

PDF

Video

Unmaking: Enabling and Celebrating the Creative Material of Failure, Destruction, Decay, and Deformation (ACM CHI 2021)

The access and growing ubiquity of digital fabrication has ushered in a celebration of creativity and “making.” However, the focus is often on the resulting static artifact or the creative process and tools to design it. We envision a post-making process that extends past these final static objects — not just in their making but in their “unmaking.” By drawing from artistic movements such as Auto-Destructive Art, intentionally inverting well-established engineering principles of structurally sound designs, and safely misusing unstable materials, we demonstrate an important extension to making — unmaking. In this paper, we provide designers with a new vocabulary of unmaking operations within standard 3D modeling tools. We demonstrate how such designs can be realized using a novel multi-material 3D printing process. Finally, we detail how unmaking allows designs to change over time, is an ally to sustainability and re-usability, and captures themes of “aura,” emotionality, and personalization.

DOI

PDF

Video

Page

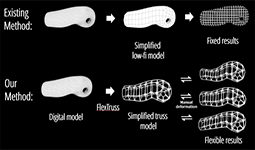

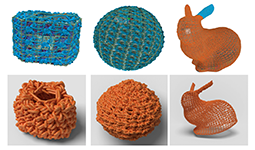

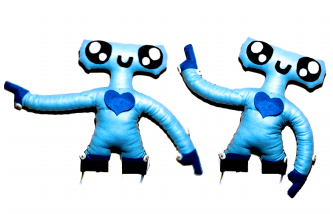

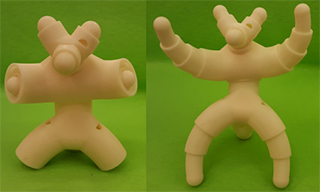

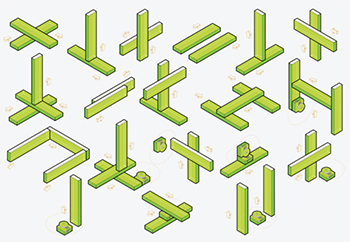

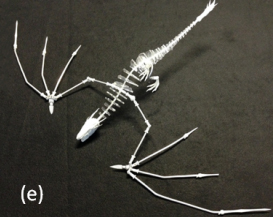

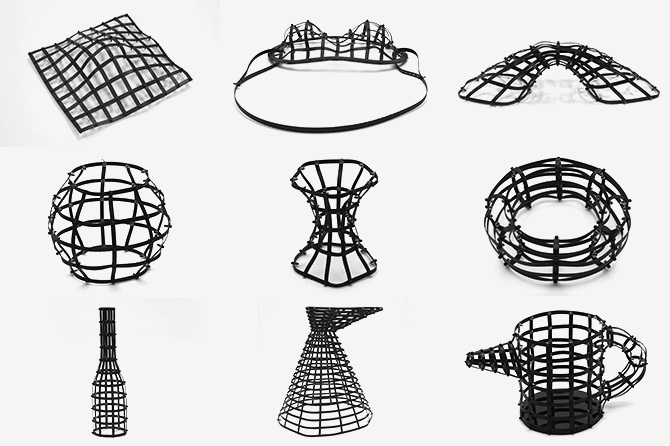

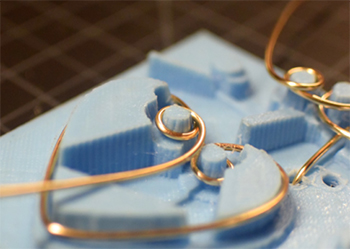

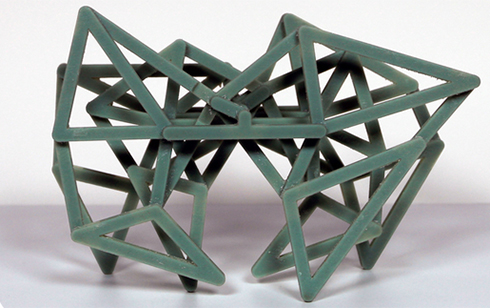

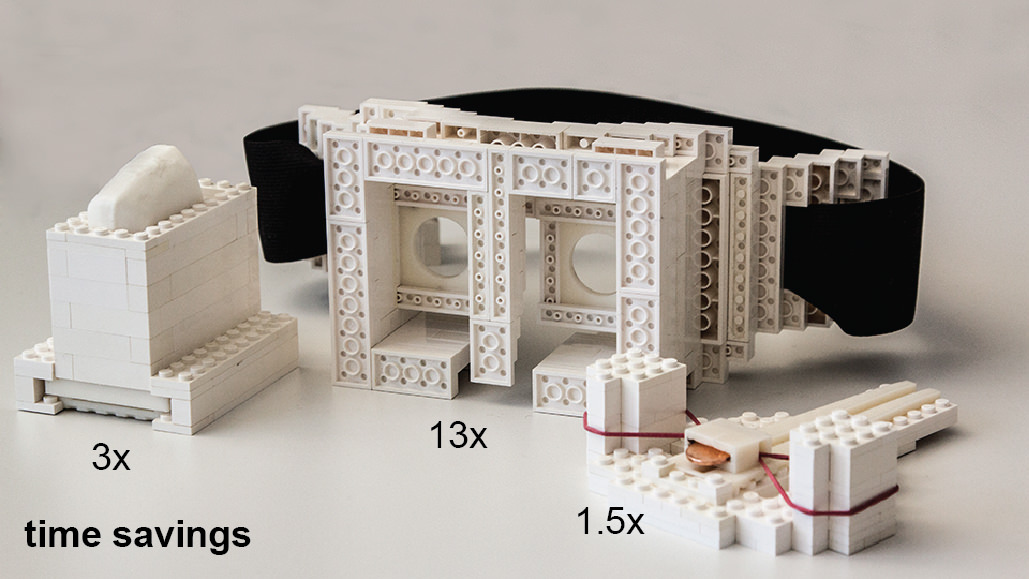

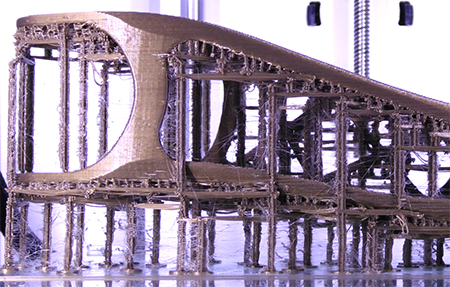

FlexTruss: A Computational Threading Method for Multi-material, Multi-form and Multi-use Prototyping (ACM CHI 2021)

3D printing, as a rapid prototyping technique, usually fabricates objects that are difficult to modify physically. This paper presents FlexTruss, a design and construction pipeline based on the assembly of modularized truss-shaped objects fabricated with conventional 3D printers and assembled by threading. To create an end-to-end system, a parametric design tool with an optimal Euler path calculation method is developed, which can support both inverse and forward design workflow and multi-material construction of modular parts. In addition, the assembly of truss modules by threading is evaluated with a series of application cases to demonstrate the affordance of FlexTruss. We believe that FlexTruss extends the design space of 3D printing beyond typically hard and fixed forms, and it will provide new capabilities for designers and researchers to explore the use of such flexible truss structures in human-object interaction.

DOI

PDF

Video

ShrinCage: 4D Printing Accessories that Self-Adapt (ACM CHI 2021)

3D printing technology makes Do-It-Yourself and reforming everyday objects a reality. However, designing and fabricating attachments that can seamlessly adapt existing objects to extended functionality is a laborious process, which requires accurate measuring, modeling, manufacturing, and assembly. This paper presents ShrinCage, a 4D printing system that allows novices to easily create shrinkable adaptations to fit and fasten existing objects. Specifically, the design tool presented in this work aid in the design of attachment that adapts to irregular morphologies, which accommodates the variations in measurements and fabrication, subsequently simplifying the modeling and assembly processes. We further conduct mechanical tests and user studies to evaluate the availability and feasibility of this method. Numerous application examples created by ShrinCage prove that it can be adopted by aesthetic modification, assistive technology, repair, upcycling, and augmented 3D printing.

DOI

PDF

Video

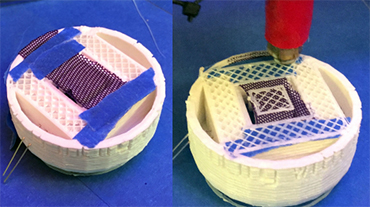

Exquisite Fabrication: Exploring Turn-taking between Designers and Digital Fabrication Machines (ACM CHI 2021)

Digital fabrication and craftsmanship is entering into a new phase with increasing levels of complexity and a renewed desire for composites and cross-material experimentation. However, allowing work to travel from machine to machine, remains a challenge in terms of workflow, communication, orientation and material. Based on an exploration to combine embroidery and 3D printing in the pursuit of inflatable solutions, we propose the metaphor of the drawing game Exquisite Corpse to outline the three emerging concerns: turn taking, orientation and trade-offs. We propose a set of guidelines that suggest ways in which, we may allow different digital fabrication machines to be used in sequence, as a method for adding complexity to the things we make and the ways our machines may talk to one another.

DOI

PDF

Video

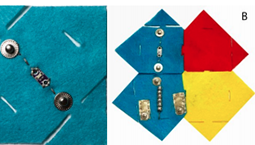

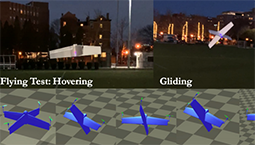

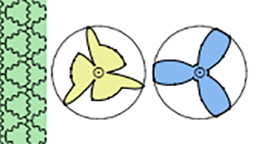

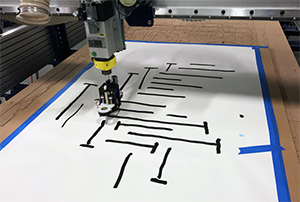

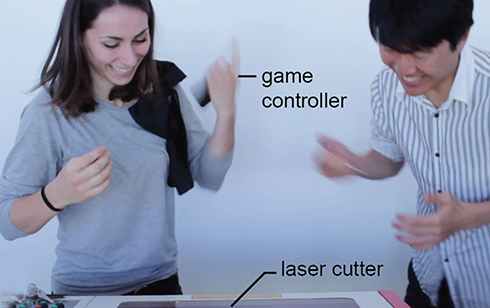

LaserFactory: A Laser Cutter-based Electromechanical Assembly and Fabrication Platform to Make Functional Devices & Robots (ACM CHI 2021)

LaserFactory is an integrated fabrication process that augments a commercially available fabrication machine to support the manufacture of fully functioning devices without human intervention. In addition to creating 2D and 3D mechanical structures, LaserFactory creates conductive circuit traces with arbitrary geometries, picks-and-places electronic and electromechanical components, and solders them in place. To enable this functionality, we make four contributions. First, we build a hardware add-on to the laser cutter head that can deposit silver circuit traces and assemble components. Second, we develop a new method to cure dispensed silver using a CO2 laser. Third, we build a motion-based signaling method that allows our system to be readily integrated with commercial laser cutters. Finally, we provide a design and visualization tool for making functional devices with LaserFactory. Having described the LaserFactory system, we demonstrate how it is used to fabricate devices such as a fully functioning quadcopter and a sensor-equipped wristband. Our evaluation shows that LaserFactory can assemble a variety of differently sized components (up to 65g), that these can be connected by narrow traces (down to 0.75mm) that become highly conductive after laser soldering (3.2Ω/m), and that our acceleration-based sensing scheme works reliably (to 99.5% accuracy).

DOI

PDF

Video

Page

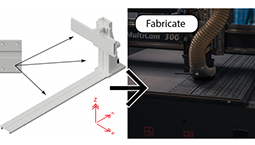

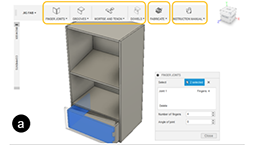

Fabricaide: Fabrication-Aware Design for 2D Cutting Machines (ACM CHI 2021)

Designers of machine-cut objects must often consider whether and how their design can be fabricated with their available materials. In contrast to tools that support preparing finished designs for fabrication, we investigate shortening the feedback loop between design creation and fabrication preparation. To this end, we present Fabricaide, a fabrication-aware tool that interleaves the processes of creating and preparing designs for fabrication. By providing live feedback on how parts should be placed onto material sheets, analyzing how much material is consumed, and alerting users when designs are infeasible, Fabricaide enables users to proactively tailor their design to their available material. Fabricaide achieves this with a custom packing algorithm that arranges parts onto material sheets at interactive speeds. Our qualitative user study shows how Fabricaide can support different workflows, encourage material-conscious design practices, and provide insights on how to further improve similar interfaces in the future.

DOI

PDF

Video

Page

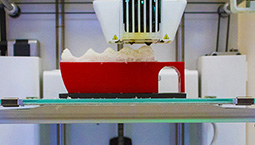

Scrappy: Using Scrap Material as Infill to Make Fabrication More Sustainable (ACM CHI 2021)

We present a software system for fused deposition modelling 3D printing that replaces infill material with scrap to reduce material and energy consumption. Example scrap objects include unused 3D prints from prototyping and calibration, household waste like coffee cups, and off-cuts from other fabrication projects. To achieve this, our system integrates into an existing CAD workflow and manages a database of common items, previous prints, and manually entered objects. While modelling in a standard CAD application, the system suggests objects to insert, ranked by how much infill material they could replace. This computation extends an existing nesting algorithm to determine which objects fit, optimize their alignment, and adjust the enclosing mesh geometry. While printing, the system uses custom tool-paths and animated instructions to enable anyone nearby to manually insert the scrap material.

DOI

PDF

Video

Page

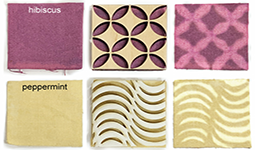

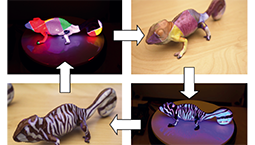

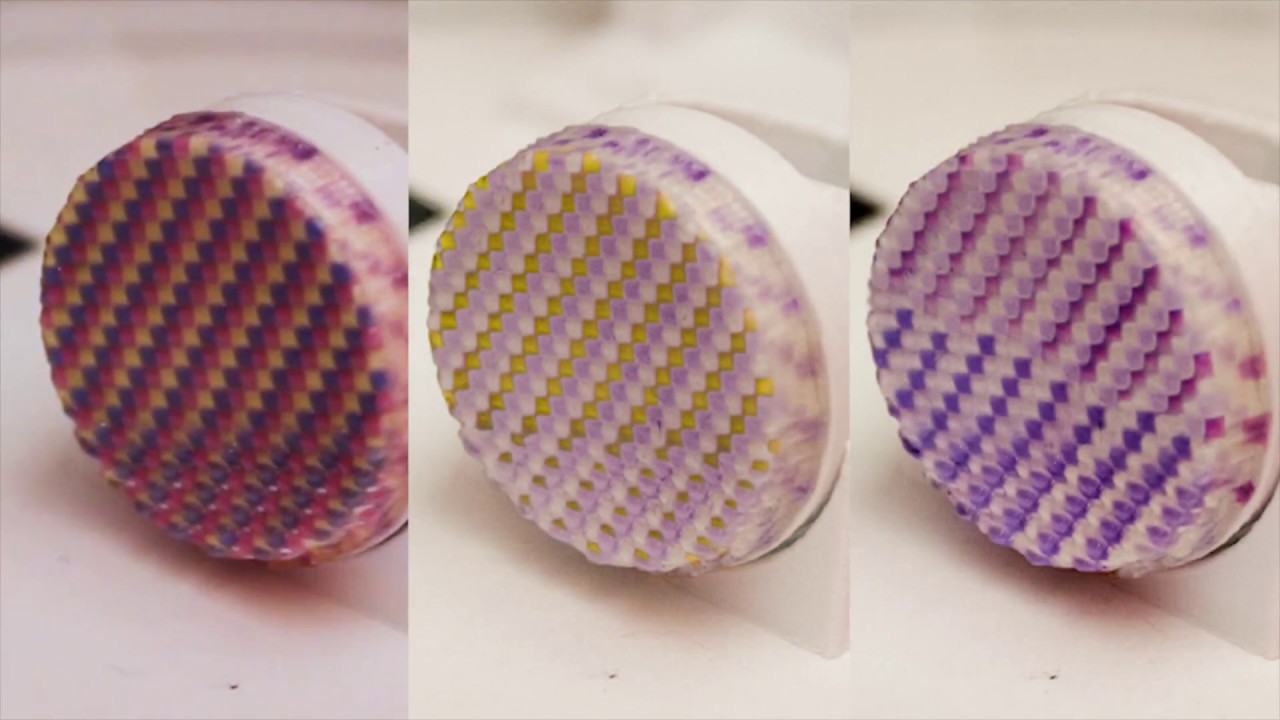

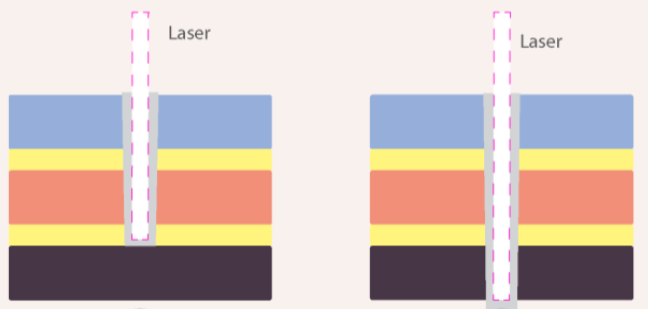

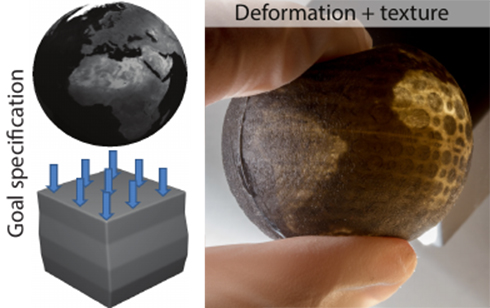

ChromoUpdate: Fast Design Iteration of Photochromic Color Textures Using Grayscale Previews and Local Color Updates (ACM CHI 2021)

ChromoUpdate is a texture transfer system for fast design iteration. For the early stages of design, ChromoUpdate provides a fast grayscale preview that enables a texture to be transferred in under one minute. Once designers are satisfied with the grayscale texture, ChromoUpdate supports designers in coloring the texture by transitioning individual pixels directly to a desired target color. Finally, if designers need to make a change to the color texture already transferred, ChromoUpdate can quickly transition individual pixels from one color to a new target color. ChromoUpdate accomplishes this by (1) using a UV projector rather than a UV LED, which enables pixels to be saturated individually rather than resetting the entire texture to black, and (2) providing two new texture transfer algorithms that allow for fast grayscale previews and color-to-color transitions. Our evaluation shows a significant increase in texture transfer speed for both the grayscale preview (89%) and color-to-color updates (11%).

DOI

PDF

Video

Page

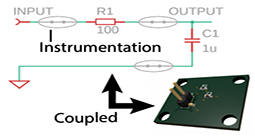

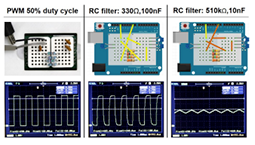

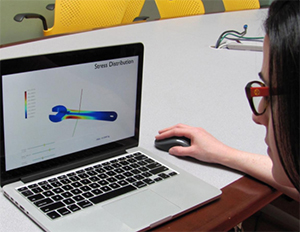

Coupling Simulation and Hardware for Interactive Circuit Debugging (ACM CHI 2021)

Simulation offers many advantages when designing analog circuits. Designers can explore alternatives quickly, without added cost or risk of hardware faults. However, it is challenging to use simulation as an aid during interactive debugging of physical circuits, due to difficulties in comparing simulated analyses with hardware measurements. Designers must continually configure simulations to match the state of the physical circuit (e.g. capturing sensor inputs), and must manually rework the hardware to replicate changes or analyses performed in simulation. We propose techniques leveraging instrumentation and programmable test hardware to create a tight coupling between a physical circuit and its simulated model. Bridging these representations helps designers to compare simulated and measured behaviors, and to quickly perform analytical techniques on hardware (e.g. parameter-response analysis) that are typically cumbersome outside of simulation. We implement these techniques in a prototype and show how it aids in efficiently debugging a variety of analog circuits.

DOI

PDF

Video

Page

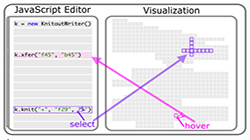

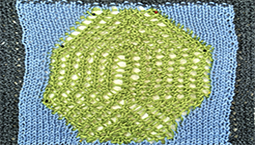

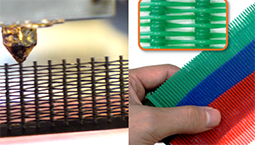

KnitUI: Fabricating Textile Sensor and User Interface with Machine Knitting (ACM CHI 2021)

With the recent interest in wearable electronics and smart garments, digital fabrication of sensing and interactive textiles is in increasing demand. Recently, advances in digital machine knitting offer opportunities for the programmable, rapid fabrication of soft, breathable textiles. In this paper, we present KnitUI, a novel, accessible machine-knitted user interface based on resistive pressure sensing. Employing conductive yarns and various machine knitting techniques, we computationally design and automatically fabricate the double-layered resistive sensing structures as well as the coupled conductive connection traces with minimal manual post-processing. We present an interactive design interface for users to customize KnitUI’s colors, sizes, positions, and shapes. After investigating design parameters for the optimized sensing and interactive performance, we demonstrate KnitUI as a portable, deformable, washable, and customizable interactive and sensing platform. It obtains diverse applications, including wearable user interfaces, tactile sensing wearables, and artificial robot skin.

DOI

PDF

Video

Page

Thermoformed Circuit Boards: Fabrication of highly conductive freeform 3D printed circuit boards with heat bending (ACM CHI 2021)

Fabricating 3D printed electronics using desktop printers has become more accessible with recent developments in conductive thermoplastic filaments. Because of their high resistance and difficulties in printing traces in vertical directions, most applications are restricted to capacitive sensing. In this paper, we introduce Thermoformed Circuit Board (TCB), a novel approach that employs the thermoformability of the 3D printed plastics to construct various double-sided, rigid and highly conductive freeform circuit boards that can withstand high current applications through copper electroplating. To illustrate the capability of the TCB, we showcase a range of examples with various shapes, electrical characteristics and interaction mechanisms. We also demonstrate a new design tool extension to an existing CAD environment that allows users to parametrically draw the substrate and conductive trace, and export 3D printable files. TCB is an inexpensive and highly accessible fabrication technique intended to broaden HCI researcher participation.

DOI

PDF

Video

Page

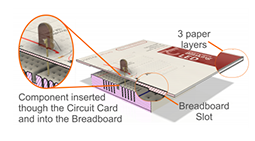

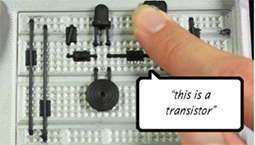

AccessibleCircuits: Adaptive Add-On Circuit Components for People with Blindness or Low Vision (ACM CHI 2021)

In this paper, we propose the designs for low cost and 3D-printable add-on components to adapt existing breadboards, circuit components and electronics tools for blind or low vision (BLV) users. Through an initial user study, we identified several barriers to entry for beginners with BLV in electronics and circuit prototyping. These barriers guided the design and development of our add-on components. We focused on developing adaptations that provide additional information about the specific component pins and breadboard holes, modify tools to make them easier to use for users with BLV, and expand non-visual feedback (e.g., audio, tactile) for tasks that require vision. Through a second user study, we demonstrated that our adaptations can effectively overcome the accessibility barriers in breadboard circuit prototyping for users with BLV.

DOI

PDF

Video

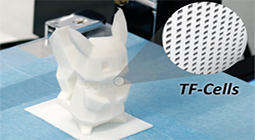

Designing Metamaterial Cells to Enrich Thermoforming 3D Printed Object for Post-Print Modification (ACM CHI 2021)

In this paper, we present a metamaterial structure called thermoformable cells, TF-Cells, to enrich thermoforming for post-print modification. So far, thermoforming is limitedly applied for modifying a 3D printed object due to its low thermal conductivity. TF-Cells consists of beam arrays that affluently pass hot air and have high heat transference. Through heating the embedded TF-Cells of the printed object, users can modify not only the deeper area of the object surface but also its form factor. With a series of technical experiments, we investigated TF-Cells’ thermoformability, depending on their structure’s parameters, orientations, and heating conditions. Next, we present a series of compound cells consisting of TF-Cells and solid structure to adjust stiffness or reduce undesirable shape deformation. Adapting the results from the experiments, we built a simple tool for embedding TF-Cells into a 3D model. Using the tool, we implemented examples under contexts of mechanical fitting, ergonomic fitting, and aesthetic tuning.

DOI

PDF

Video

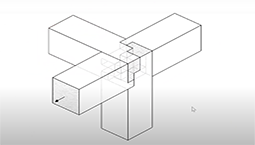

Assembler3: 3D Reconstruction of Laser-Cut Models (ACM CHI 2021)

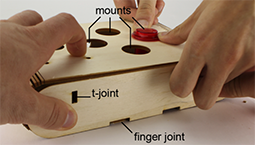

We present Assembler3 a software tool that allows users to perform 3D parametric manipulations on 2D laser cutting plans. Assembler3 achieves this by semi-automatically converting 2D laser cutting plans to 3D, where users modify their models using available 3D tools (kyub), before converting them back to 2D. In our user study, this workflow allowed users to modify models 10x faster than using the traditional approach of editing 2D cutting plans directly. Assembler3 converts models to 3D in 5 steps: (1) plate detection, (2) joint detection, (3) material thickness detection, (4) joint matching based on hashed joint "signatures", and (5) interactive reconstruction. In our technical evaluation, Assembler3 was able to reconstruct 100 of 105 models. Once 3D-reconstructed, we expect users to store and share their models in 3D, which can simplify collaboration and thereby empower the laser cutting community to create models of higher complexity.

DOI

PDF

Video

Page

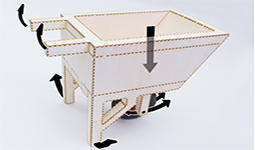

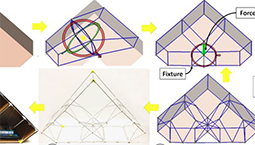

FastForce: Real-Time Reinforcement of Laser-Cut Structures (ACM CHI 2021)

We present fastForce, a software tool that detects structural flaws in laser cut 3D models and fixes them by introducing additional plates into the model, thereby making models up to 52x stronger. By focusing on a specific type of structural issue, i.e., poorly connected sub-structures in closed box structures, fastForce achieves real-time performance (106x faster than finite element analysis, in the specific case of the wheelbarrow from Figure 1). This allows fastForce to fix structural issues continuously in the background, while users stay focused on editing their models and without ever becoming aware of any structural issues. In our study, six of seven participants inadvertently introduced severe structural flaws into the guitar stands they designed. Similarly, we found 286 of 402 relevant models in the kyub [1] model library to contain such flaws. We integrated fastForce into a 3D editor for lasercutting (kyub) and found that even with high plate counts fastForce achieves real-time performance.

DOI

PDF

Video

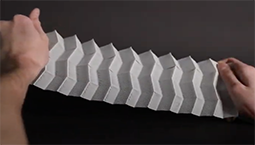

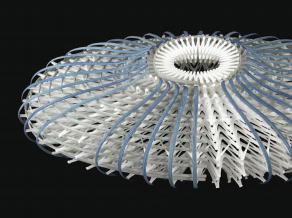

Developable Metamaterials: Mass-fabricable Metamaterials by Laser-Cutting Elastic Structures (ACM CHI 2021)

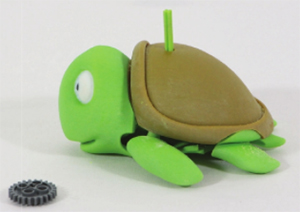

We propose a novel design of engineered, structured materials that leverages fast fabrication technologies, pushing them towards mass-fabrication. Specifically, our metamaterial is designed to be laser cut, to approximate the volumetric shape and allow for locally varying compliance. Traditional mechanical metamaterials consist of intricate cells arranged on a 3-dimensional grid, limiting them to 3D printing—which is slow. Our metamaterial is designed for laser cutting, which is drastically faster. Our structures are best described as ruffled strips of thin sheet material, such as paper, plastics, metals, etc. Users can interactively define the ruffles’ anisotropic stiffness directions and local density. Our computational design tool assists users by automatically optimizing the ruffle to fill the shape’s volume, and exporting the flat ruffle design ready for cutting. We demonstrate how such ruffled metamaterials can be utilized for, e.g., custom toys with locally varying compliance, custom packaging material, or lightweight formwork for architectural shells.

DOI

PDF

Video

Page

TapeBlocks: A Making Toolkit for People Living with Intellectual Disabilities (ACM CHI 2021)

The accessibility and affordability of tangible electronic toolkits are significant barriers to their uptake by people with disabilities. We present the design and evaluation of TapeBlocks, a low-cost, low-fidelity toolkit intended to be accessible for people with intellectual disabilities while promoting creativity and engagement. We evaluated TapeBlocks by interviewing makers, special educational needs teachers and support coaches. Analysis of these interviews informed the design of a series of maker workshops using TapeBlocks with young adults living with intellectual disabilities, led by support coaches with support from the research team. Participants were able to engage with TapeBlocks and making, eventually building their own TapeBlocks to make personal creations. Our evaluation reveals how TapeBlocks supports accessible making and playful discovery of electronics for people living with disabilities, and addresses a gap in existing toolkits by being tinkerable, affordable and having a low threshold for engagement.

DOI

PDF

Video

Page

"Beyond 3D printers”: Understanding Long-Term Digital Fabrication Practices for the Education of Visually Impaired or Blind Youth (ACM CHI 2021)

Disability professionals could use digital fabrication tools to provide customised assistive technologies or accessible media beneficial to the education of Blind or visually impaired youth. However, there is little documentation of long-term practices with these tools by professionals in this field, limiting our ability to support their work. We report on such practices in a French organisation, providing disability educational services and using digital fabrication since 2013, for six years. We trace how professionals defined how digital fabrication could and should be used through a range of projects, based on pedagogical uses and the constraints in creation, production and maintenance. We outline new research perspectives going beyond 3D printers and its promises of automation to embrace hybrid approaches currently supported by laser cutters, the learning and documentation process, and the production of accessible tactile media at a regional or national scale.

DOI

PDF

Video

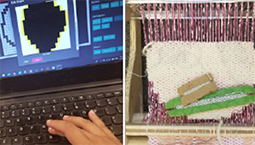

Enabling Personal Computational Handweaving with a Low-Cost Jacquard Loom (ACM CHI 2021)

We present an inexpensive tabletop loom that offers fully computational patterning while maintaining the flexibility of handweaving. Our loom can be assembled for under US$200 with 3D printed parts, and it can be controlled straightforwardly over USB. Our loom is explicitly a hand loom: that is, a weaver is required to operate the weaving process and may mediate row-by-row patterning and material specifics like yarn tension. Our approach combines the flexibility of fully analog handweaving with the computational affordances of digital fabrication: it enables the incorporation of special techniques and materials, as well as allowing for the possibility of computational and creative interventions in the weaving process itself. In taking this approach, we aim to serve a range of end users including artisans and researchers, whether for skill-building, for rapid prototyping, or for creative reflection. We describe the mechanical and electronic implementation of our loom and show examples of its use for personal fabrication.

DOI

PDF

Video

Page

Engineering Multifunctional Spacer Fabrics Through Machine Knitting (ACM CHI 2021)