Publication

Martin Nisser, Christina Chen Liao, Yuchen Chai, Aradhana Adhikari, Steve Hodges, Stefanie Mueller.

LaserFactory: An Electromechanical Assembly and Fabrication Platform Integrated with a Laser Cutter to make Functional Devices and Robots

In Proceedings of

CHI ’21.

DOI

PDF

Video

Press video

Conference Talk

Slides

Press

- BBC News

- MIT News

- Yahoo! News

- IEEE Spectrum

- Venture Beat

- Techcrunch

- Engadget

- Hackaday

- Hackster.io

- 3Dprint.com

- Designboom

- Adafruit blog

LaserFactory:

An Electromechanical Assembly and Fabrication Platform

Integrated with a Laser Cutter

to make Functional Devices and Robots.

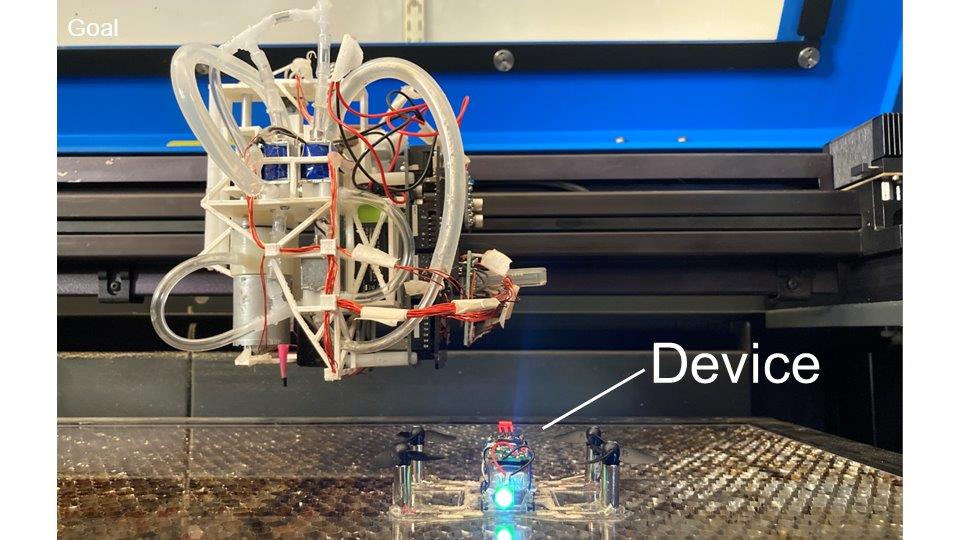

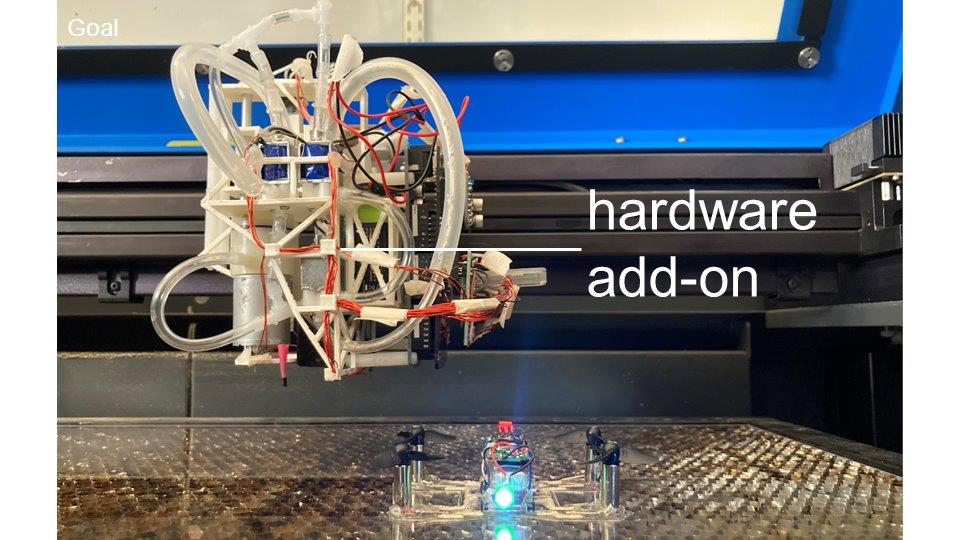

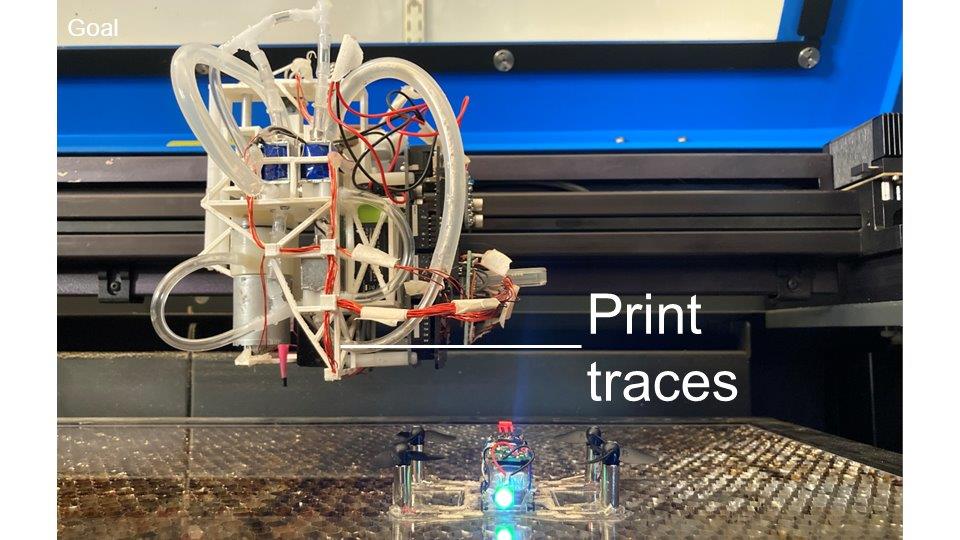

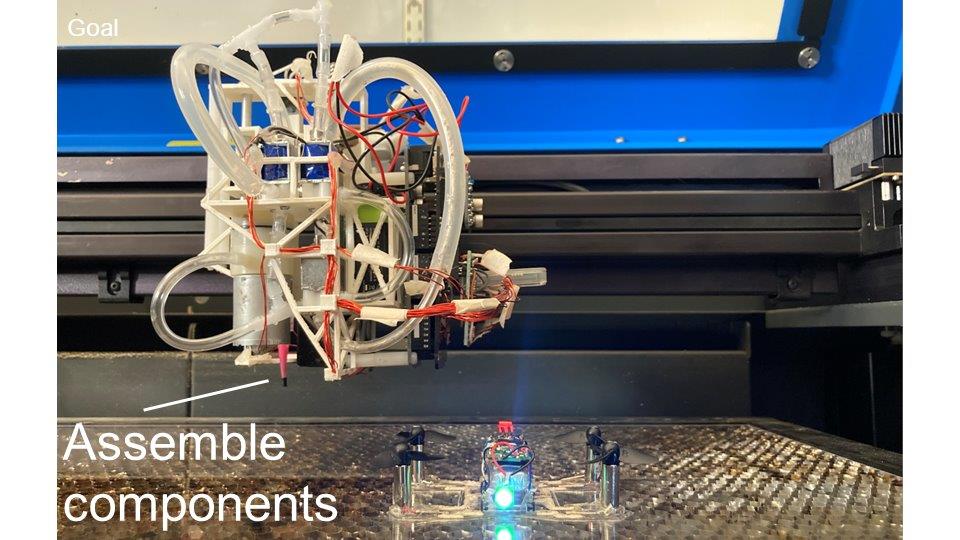

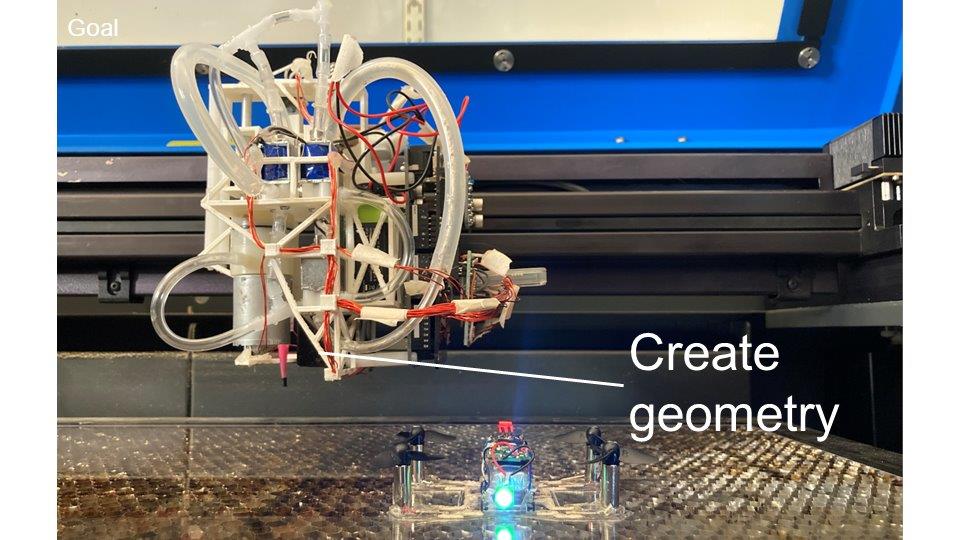

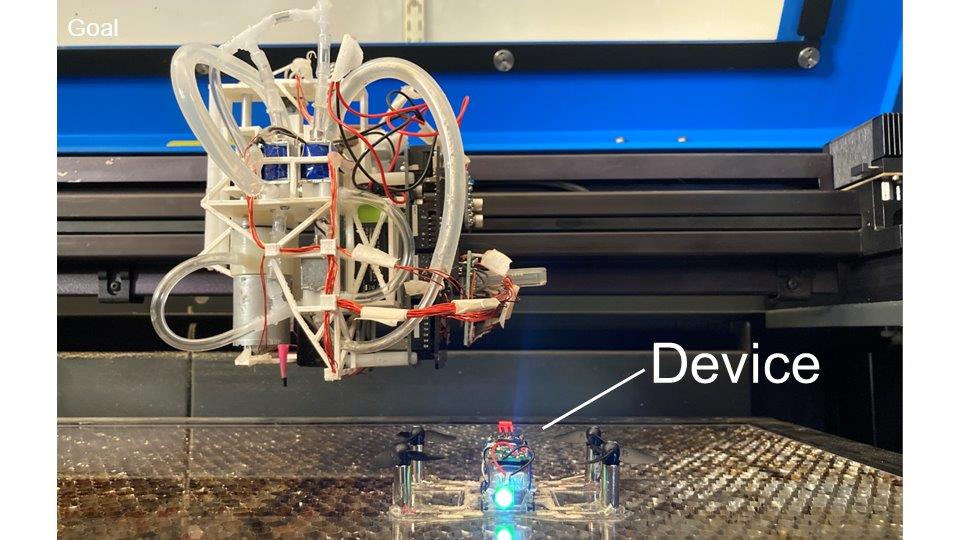

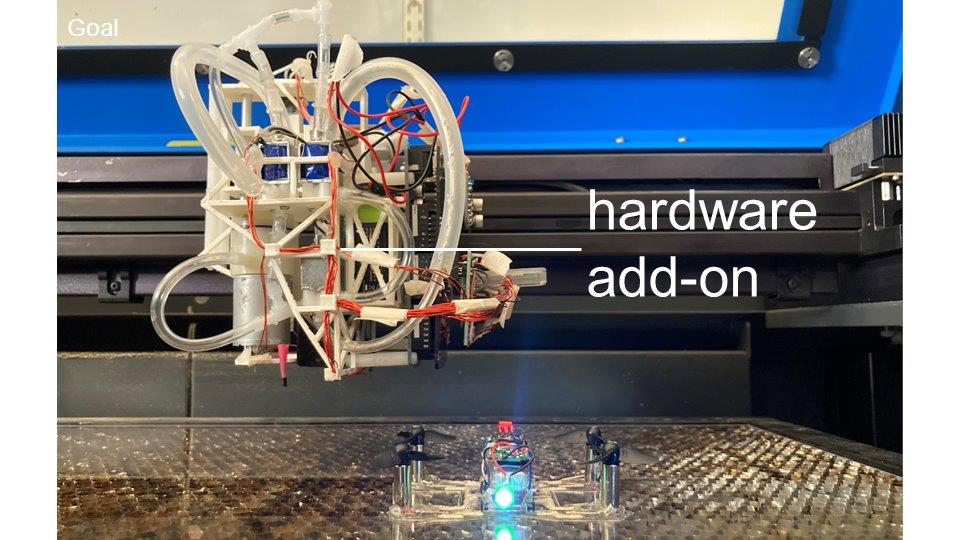

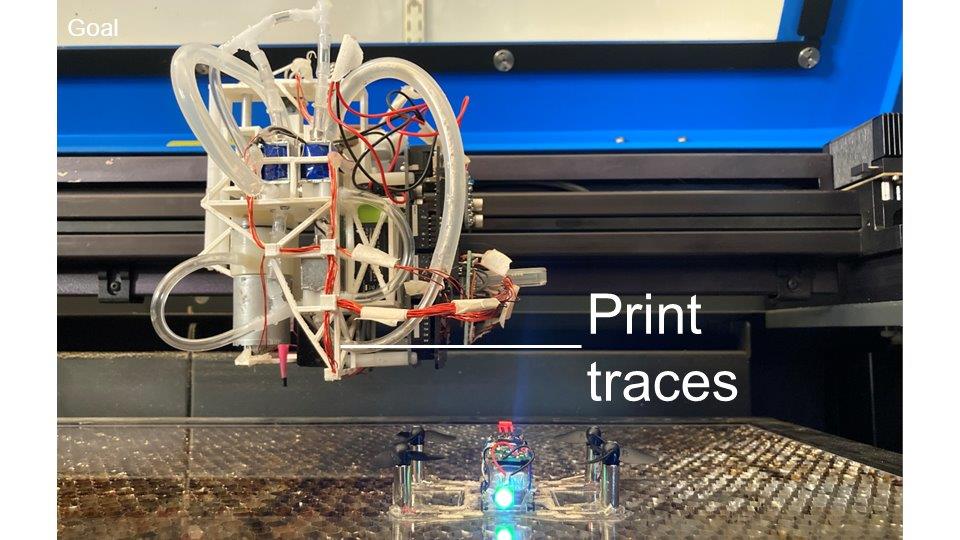

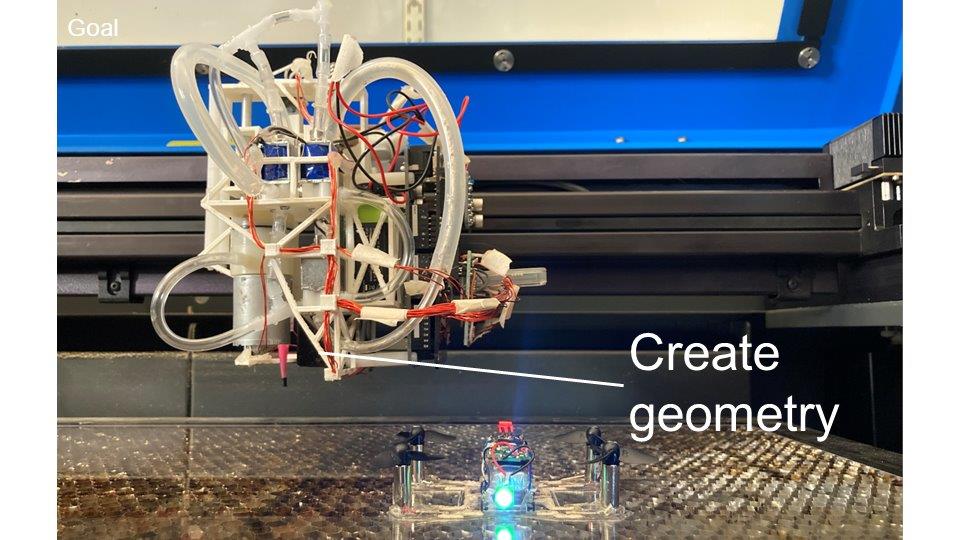

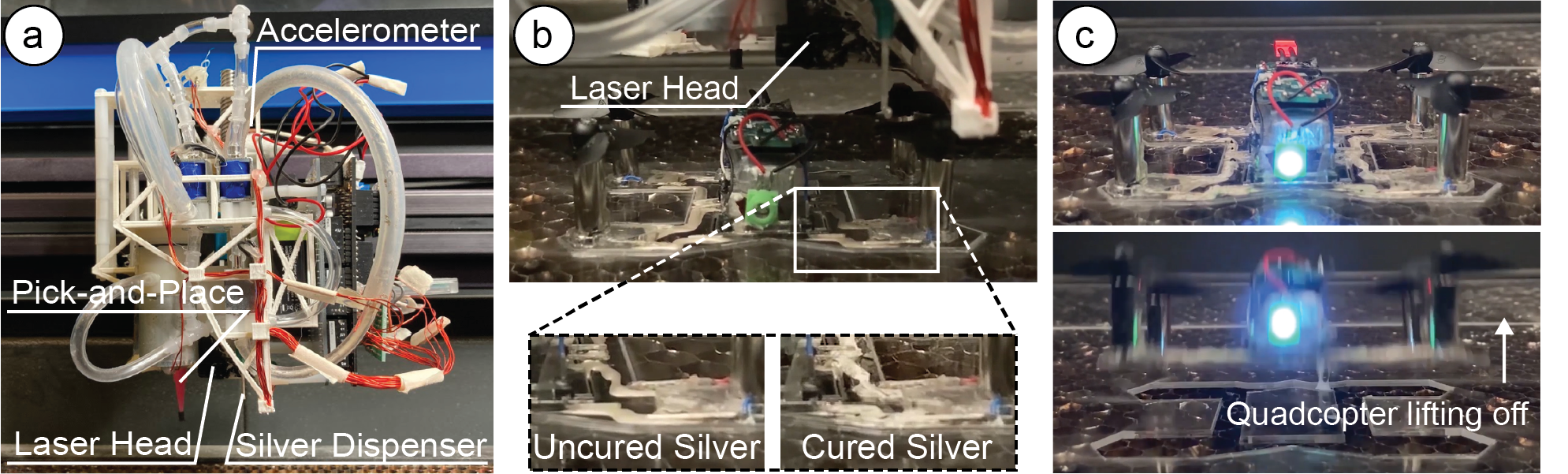

Figure 1. LaserFactory is an integrated fabrication process that creates fully functional devices. (a) Our hardware add-on to an existing laser cutter consists of a silver dispenser and pick-and-place mechanism and allows the machine to not only cut geometry, but also create circuit traces and assemble electronic components. Our accelerometer-based motion classifier enables the add-on to interface with the laser cutter without the need to change the underlying firmware. (b) To cure the deposited silver traces, we developed a laser soldering method that uses the heat of the defocused laser to make the traces conductive. (c) After laser soldering, the fabricated device is fully functional.

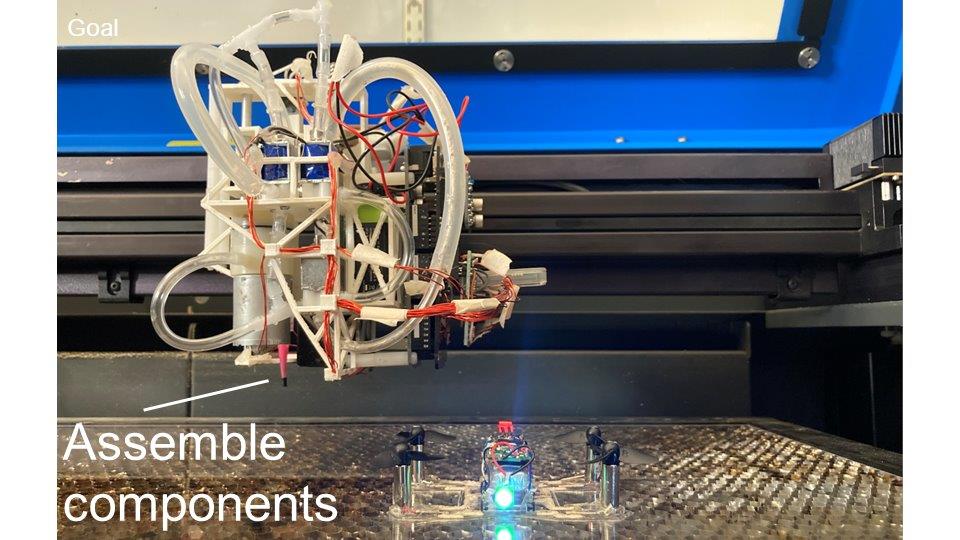

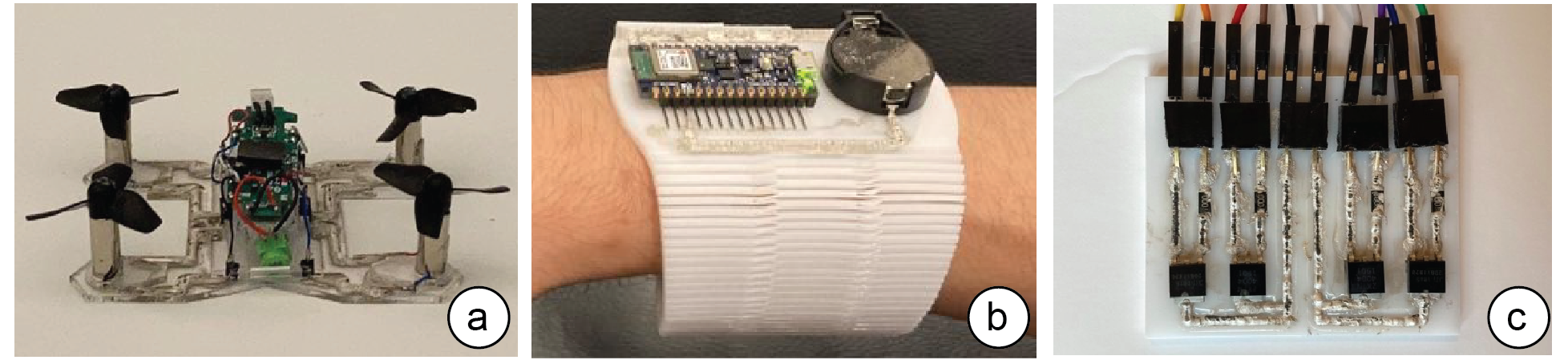

LaserFactory is an integrated fabrication process that augments a commercially available fabrication machine to support the manufacture of fully functioning devices without human intervention. In addition to creating 2D and 3D mechanical structures, LaserFactory creates conductive circuit traces with arbitrary geometries, picks-and-places electronic and electromechanical components, and solders them in place. To enable this functionality, we make four contributions. First, we build a hardware add-on to the laser cutter head that can deposit silver circuit traces and assemble components. Second, we develop a new method to cure dispensed silver using a CO2 laser. Third, we build a motion-based signaling method that allows our system to be readily integrated with commercial laser cutters. Finally, we provide a design and visualization tool for making functional devices with LaserFactory. Having described the LaserFactory system, we demonstrate how it is used to fabricate devices such as a fully functioning quadcopter and a sensor-equipped wristband. Our evaluation shows that LaserFactory can assemble a variety of differently sized components (up to 65g), that these can be connected by narrow traces (down to 0.75mm) that become highly conductive after laser soldering (3.2 Ohm/m), and that our acceleration-based sensing scheme works reliably (to 99.5% accuracy).

Introduction

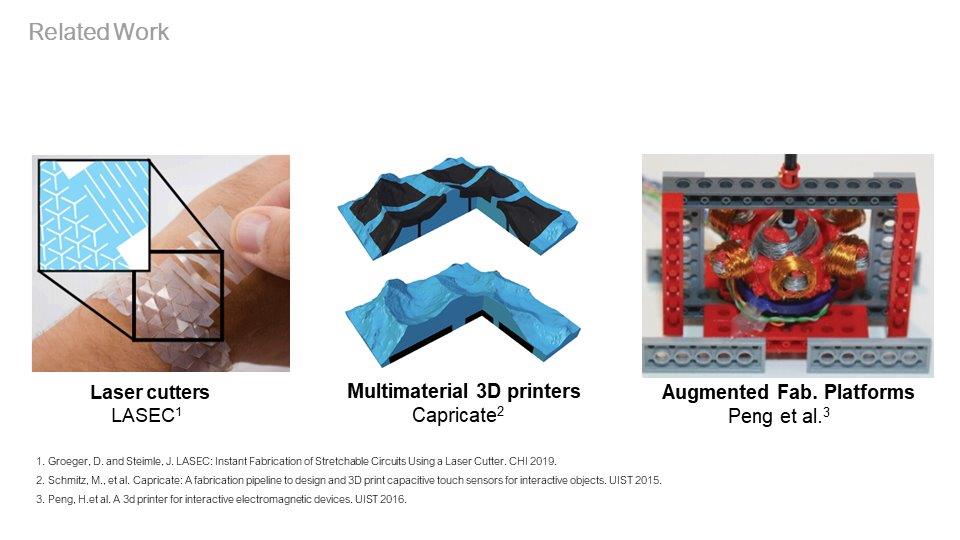

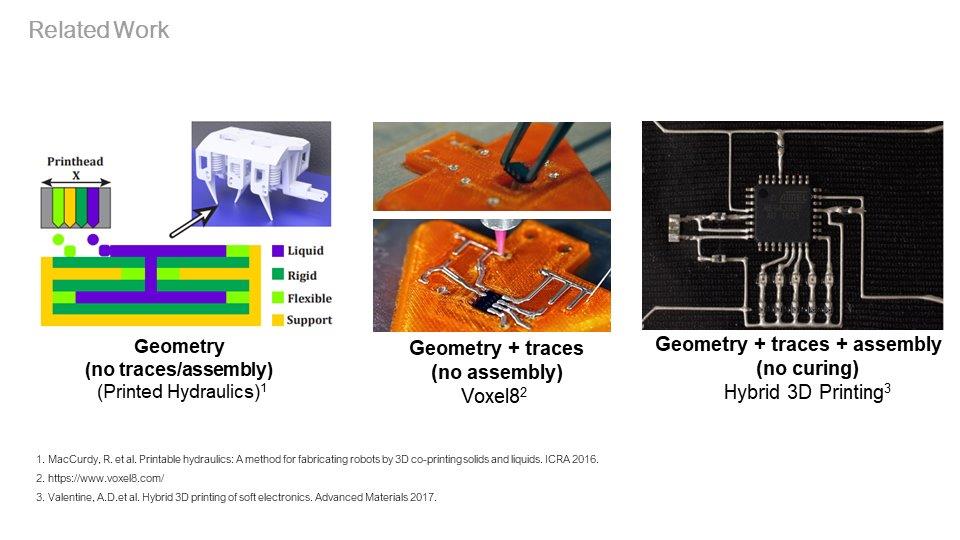

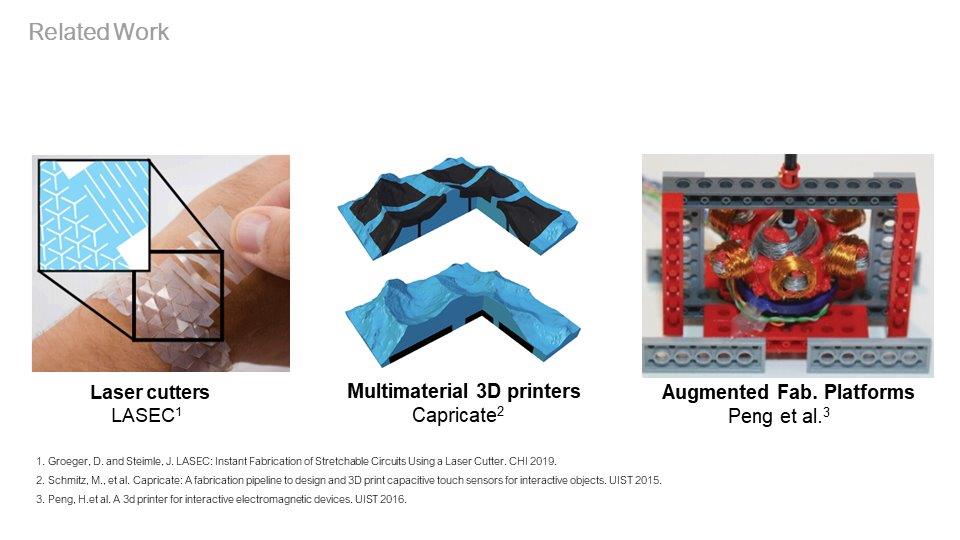

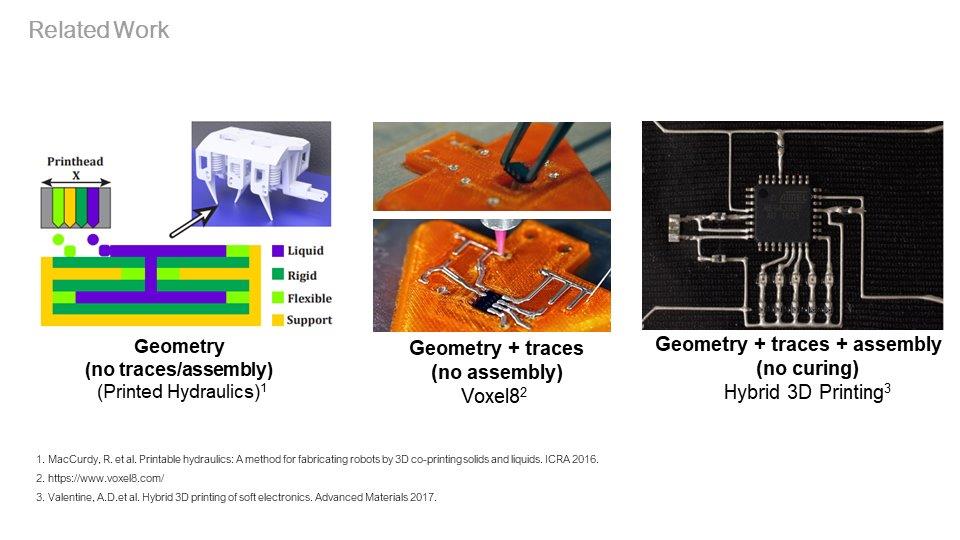

To fabricate a fully functional device—a 3D structure with integrated electronics and actuators—requires three steps; (1) fabricating the device geometry, (2) creating conductive circuit traces, and (3) populating the structure with electronic components. Researchers have in recent decades developed numerous personal fabrication methods that democratize the creation of such functional devices. These methods focus on extending the abilities of existing fabrication machines designed to create geometry to also permit creating conductive traces, for example by generating hollow internal pipes for 3D prints that can be filled with conductive material [20], or using laser cutters to selectively ablate conductive films that can be populated with components [5]. However as yet, personal fabrication machines do not have the ability to integrate all three steps,and instead rely on human intervention to complete the fabrication procedure. As such, the fabrication of functional devices continues to demand engineering expertise, for example, to etch PCBs or solder components. In addition, repeatability and precision in the construction is compromised, as techniques based on manual intervention impede the ability for engineered devices to be made to specification.

In this paper, we build upon the above systems by proposing a fabrication machine that creates device geometry, adds circuit traces,and then incorporates electronic components in an automated way. With such a machine, users only need to load components into a storage area at the beginning of the fabrication process and execute the fabrication file in order to create a fully functional device. Since many devices can be created from circuits assembled from a subset of basic electronic parts such as transistors, resistors and capacitors, loading a set of these allows users to download and print a variety of different circuits such as H-bridges and op-amps in order to build devices capable of more complex tasks such as motor driving, display rendering and signal conditioning.

There are two possible pathways to create a fabrication platform that can fabricate geometry, circuit traces, and assemble electronic components: either augmenting an existing fabrication device with a custom hardware add-on or building a new fabrication device from the ground up. The benefit of augmenting an existing fabrication device is that existing infrastructure can be leveraged and thus the engineering effort required to create the functionality can be potentially reduced. In addition, the new fabrication capabilities can be made available to a wide range of users who already own such devices and are familiar with them. However, augmenting existing devices comes with its own challenges since the proprietary software running commercial fabrication devices typically does not allow for modifications, which are necessary to instruct a custom hardware add-on to perform its function. To solve this issue, we developed a technique that allows a hardware add-onto communicate with the commercial fabrication device without the need to change the underlying code. The key idea is to embed signals into the fabrication file that result in specific movements of the fabrication head, which can be sensed with a motion-sensor (accelerometer) attached to the head (Figure 1a). Such signals can inform the hardware add-on about which parts of the fabrication file the fabrication head is currently executing and thus instruct the hardware add-on to perform its function at the right time.

While the motion-based signaling technique for augmenting existing fabrication devices works for different types of fabrication machines granted they use a fabrication head on a motion platform and allow custom motion lines to be written to the fabrication file, our platform centers on a commercial laser cutter. We chose a laser cutter as the fabrication platform due to its speed of operation and thus quick turn-around time for prototyping. To augment the laser cutter with the ability to create circuit traces and assemble electronic components, we developed a custom hardware add-on consisting of a silver dispenser and a pick-and-place mechanism that is mounted onto the existing laser cutter head (Figure 1a). When the embedded motion lines in the fabrication file indicate that a circuit trace needs to be fabricated, the silver dispenser starts laying down silver while the laser’s motion carriage continues its movement along the path encoded in the design. Similarly, when the embedded motion lines in the fabrication file indicate that a component needs to picked and placed, a pump connected to the pick-and-place mechanism creates negative pressure for picking up the component.

Since the silver is not yet conductive after it has been dispensed, we developed a technique that uses the heat of the laser for thermal curing of the dispensed silver (Figure 1b). This process is also used to rigidly connect the electronic components to the circuit traces, resulting in the final assembly of the functional device. In contrast to methods that rely on carbon-based conductors and 3D printed filament (Capricate [22]), dispensing and curing the silver creates highly conductive circuit traces. In addition, the laser soldering step also removes the need for a manual curing procedure as was needed in prior work (Valentine et al. [29]). Lastly, in contrast to conductive pastes used in 3D printing-based systems such as Voxel8[31] that cure uniformly in a specified time and therefore precludes local control, laser soldering selectively cures silver paste when required once components are placed. Thus laser soldering does not rely on paste properties that must be synthesized to trade off slow curing (to allow placing components while paste remains uncured) against fast curing (to expedite fabrication).

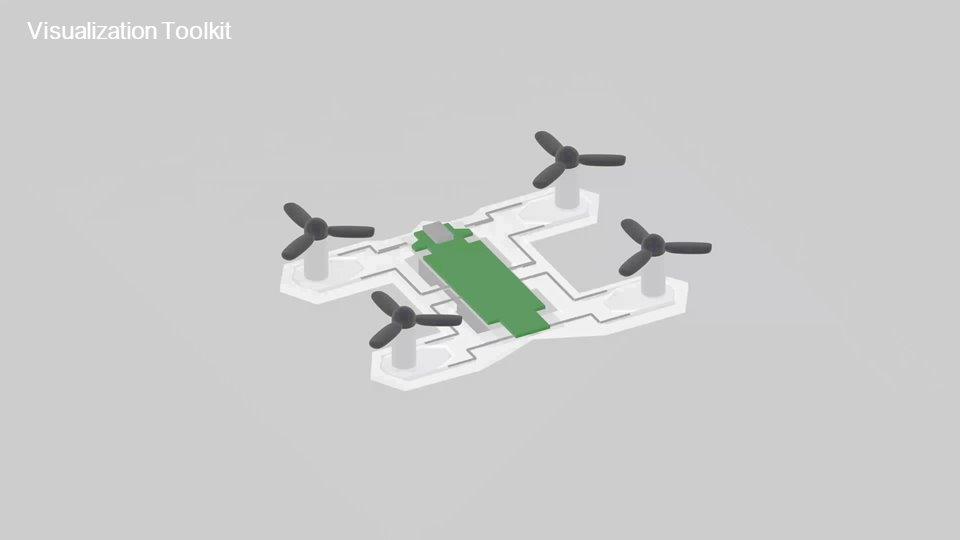

To support the design of fully functional devices that can be fabricated on our augmented fabrication machine, we also provide a software toolkit that allows users to design devices in a 2D editor by concurrently creating both their geometry and electronic layout. A custom visualization tool then provides a 3D rendering of the resulting geometry and displays the order of fabrication steps, which users can use to validate the design before making it. On export, the software then translates the user’s custom design into machine instructions embedded in a single fabrication file (.pdf) that can be fabricated using the standard laser cutter software to make the functional device in one go (Figure 1c).

In summary, this paper makes the following contributions:

Figure 1. LaserFactory is an integrated fabrication process that creates fully functional devices. (a) Our hardware add-on to an existing laser cutter consists of a silver dispenser and pick-and-place mechanism and allows the machine to not only cut geometry, but also create circuit traces and assemble electronic components. Our accelerometer-based motion classifier enables the add-on to interface with the laser cutter without the need to change the underlying firmware. (b) To cure the deposited silver traces, we developed a laser soldering method that uses the heat of the defocused laser to make the traces conductive. (c) After laser soldering, the fabricated device is fully functional.

LaserFactory is an integrated fabrication process that augments a commercially available fabrication machine to support the manufacture of fully functioning devices without human intervention. In addition to creating 2D and 3D mechanical structures, LaserFactory creates conductive circuit traces with arbitrary geometries, picks-and-places electronic and electromechanical components, and solders them in place. To enable this functionality, we make four contributions. First, we build a hardware add-on to the laser cutter head that can deposit silver circuit traces and assemble components. Second, we develop a new method to cure dispensed silver using a CO2 laser. Third, we build a motion-based signaling method that allows our system to be readily integrated with commercial laser cutters. Finally, we provide a design and visualization tool for making functional devices with LaserFactory. Having described the LaserFactory system, we demonstrate how it is used to fabricate devices such as a fully functioning quadcopter and a sensor-equipped wristband. Our evaluation shows that LaserFactory can assemble a variety of differently sized components (up to 65g), that these can be connected by narrow traces (down to 0.75mm) that become highly conductive after laser soldering (3.2 Ohm/m), and that our acceleration-based sensing scheme works reliably (to 99.5% accuracy).

Introduction

To fabricate a fully functional device—a 3D structure with integrated electronics and actuators—requires three steps; (1) fabricating the device geometry, (2) creating conductive circuit traces, and (3) populating the structure with electronic components. Researchers have in recent decades developed numerous personal fabrication methods that democratize the creation of such functional devices. These methods focus on extending the abilities of existing fabrication machines designed to create geometry to also permit creating conductive traces, for example by generating hollow internal pipes for 3D prints that can be filled with conductive material [20], or using laser cutters to selectively ablate conductive films that can be populated with components [5]. However as yet, personal fabrication machines do not have the ability to integrate all three steps,and instead rely on human intervention to complete the fabrication procedure. As such, the fabrication of functional devices continues to demand engineering expertise, for example, to etch PCBs or solder components. In addition, repeatability and precision in the construction is compromised, as techniques based on manual intervention impede the ability for engineered devices to be made to specification.

In this paper, we build upon the above systems by proposing a fabrication machine that creates device geometry, adds circuit traces,and then incorporates electronic components in an automated way. With such a machine, users only need to load components into a storage area at the beginning of the fabrication process and execute the fabrication file in order to create a fully functional device. Since many devices can be created from circuits assembled from a subset of basic electronic parts such as transistors, resistors and capacitors, loading a set of these allows users to download and print a variety of different circuits such as H-bridges and op-amps in order to build devices capable of more complex tasks such as motor driving, display rendering and signal conditioning.

There are two possible pathways to create a fabrication platform that can fabricate geometry, circuit traces, and assemble electronic components: either augmenting an existing fabrication device with a custom hardware add-on or building a new fabrication device from the ground up. The benefit of augmenting an existing fabrication device is that existing infrastructure can be leveraged and thus the engineering effort required to create the functionality can be potentially reduced. In addition, the new fabrication capabilities can be made available to a wide range of users who already own such devices and are familiar with them. However, augmenting existing devices comes with its own challenges since the proprietary software running commercial fabrication devices typically does not allow for modifications, which are necessary to instruct a custom hardware add-on to perform its function. To solve this issue, we developed a technique that allows a hardware add-onto communicate with the commercial fabrication device without the need to change the underlying code. The key idea is to embed signals into the fabrication file that result in specific movements of the fabrication head, which can be sensed with a motion-sensor (accelerometer) attached to the head (Figure 1a). Such signals can inform the hardware add-on about which parts of the fabrication file the fabrication head is currently executing and thus instruct the hardware add-on to perform its function at the right time.

While the motion-based signaling technique for augmenting existing fabrication devices works for different types of fabrication machines granted they use a fabrication head on a motion platform and allow custom motion lines to be written to the fabrication file, our platform centers on a commercial laser cutter. We chose a laser cutter as the fabrication platform due to its speed of operation and thus quick turn-around time for prototyping. To augment the laser cutter with the ability to create circuit traces and assemble electronic components, we developed a custom hardware add-on consisting of a silver dispenser and a pick-and-place mechanism that is mounted onto the existing laser cutter head (Figure 1a). When the embedded motion lines in the fabrication file indicate that a circuit trace needs to be fabricated, the silver dispenser starts laying down silver while the laser’s motion carriage continues its movement along the path encoded in the design. Similarly, when the embedded motion lines in the fabrication file indicate that a component needs to picked and placed, a pump connected to the pick-and-place mechanism creates negative pressure for picking up the component.

Since the silver is not yet conductive after it has been dispensed, we developed a technique that uses the heat of the laser for thermal curing of the dispensed silver (Figure 1b). This process is also used to rigidly connect the electronic components to the circuit traces, resulting in the final assembly of the functional device. In contrast to methods that rely on carbon-based conductors and 3D printed filament (Capricate [22]), dispensing and curing the silver creates highly conductive circuit traces. In addition, the laser soldering step also removes the need for a manual curing procedure as was needed in prior work (Valentine et al. [29]). Lastly, in contrast to conductive pastes used in 3D printing-based systems such as Voxel8[31] that cure uniformly in a specified time and therefore precludes local control, laser soldering selectively cures silver paste when required once components are placed. Thus laser soldering does not rely on paste properties that must be synthesized to trade off slow curing (to allow placing components while paste remains uncured) against fast curing (to expedite fabrication).

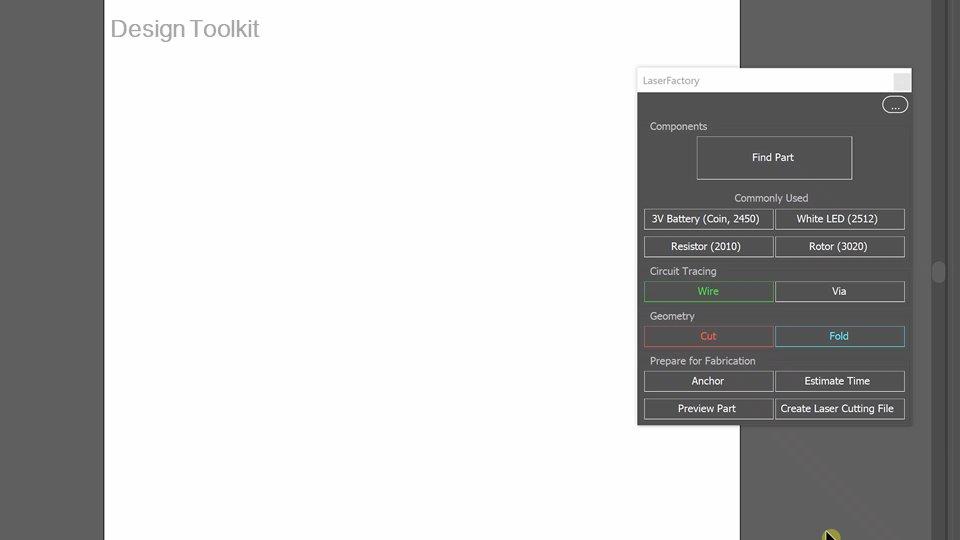

To support the design of fully functional devices that can be fabricated on our augmented fabrication machine, we also provide a software toolkit that allows users to design devices in a 2D editor by concurrently creating both their geometry and electronic layout. A custom visualization tool then provides a 3D rendering of the resulting geometry and displays the order of fabrication steps, which users can use to validate the design before making it. On export, the software then translates the user’s custom design into machine instructions embedded in a single fabrication file (.pdf) that can be fabricated using the standard laser cutter software to make the functional device in one go (Figure 1c).

In summary, this paper makes the following contributions:

- A hardware add-on consisting of a silver dispenser and a pick-and-place mechanism to augment an existing laser cutter’s functionality with the ability to create circuit traces and place components.

- Laser soldering, a technique for curing dispensed silver traces using the heat of the existing CO2 laser to create highly conductive circuit traces.

- A motion-based signaling technique for augmenting an existing fabrication platform without the need to interface with its underlying software.

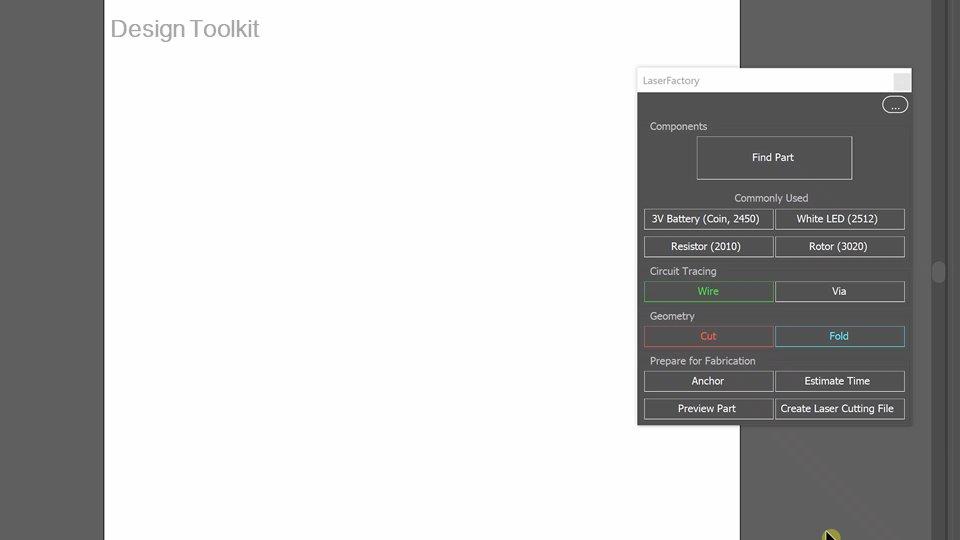

- A software toolkit consisting of three elements: a tool that supports the concurrent design of device geometry, circuit traces and electronic component layouts; a tool that visualizes the resulting 3D geometry and steps of the fabrication process; and a translation pipeline that converts the design into machine instructions for the fabrication device and hardware add-on.

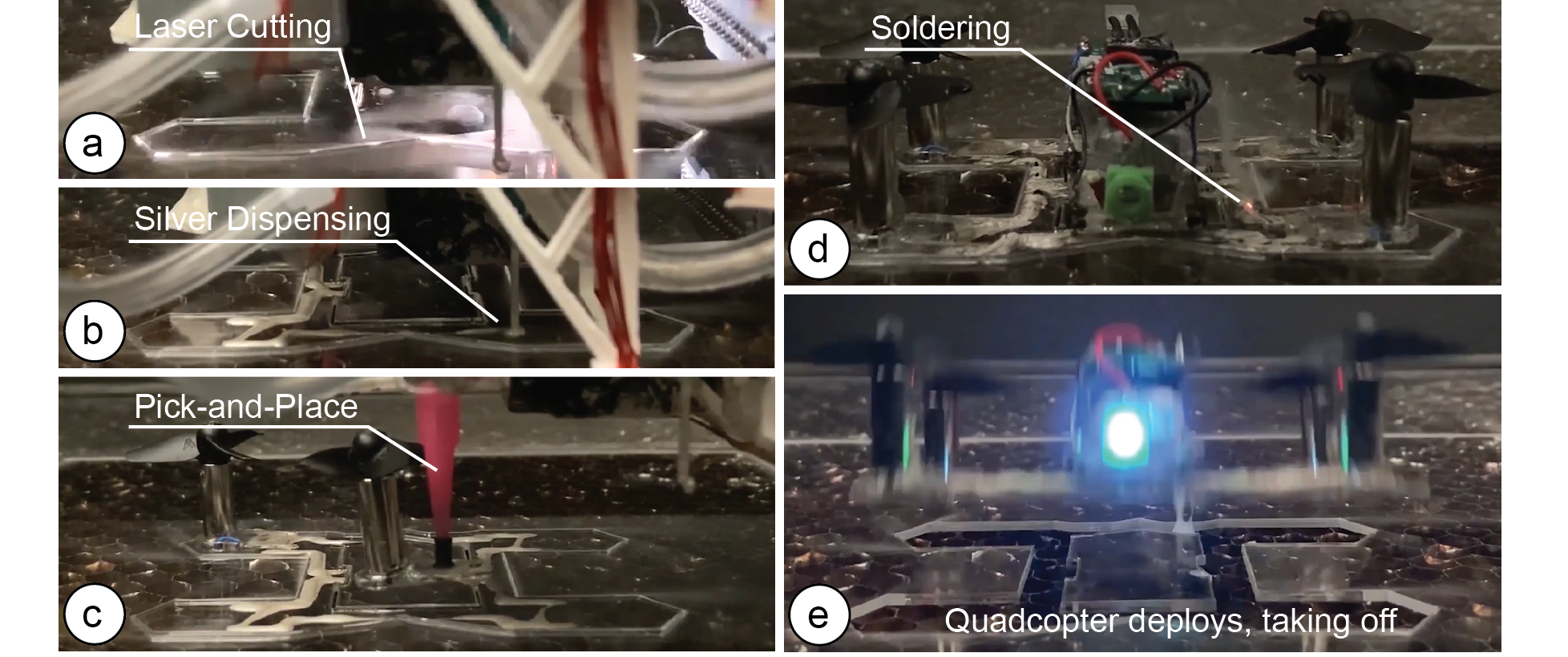

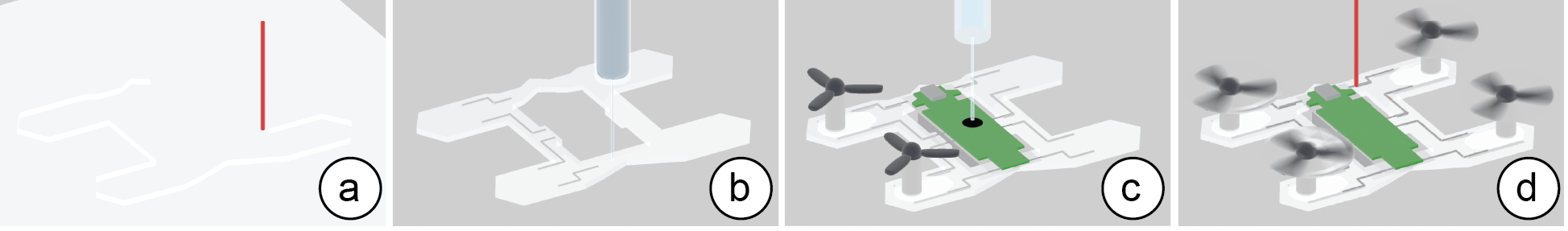

Figure 2. Making a Device with LaserFactory: (a) Cutting the device geometry, (b) dispensing silver to form the circuit traces, (c) picking-and-placing the components, here a quadcopter’s rotor, and (d) curing the uncured silver traces. (e) When the last trace is cured, the device is fully functional; here, the quadcopter lifts directly off from the platform.

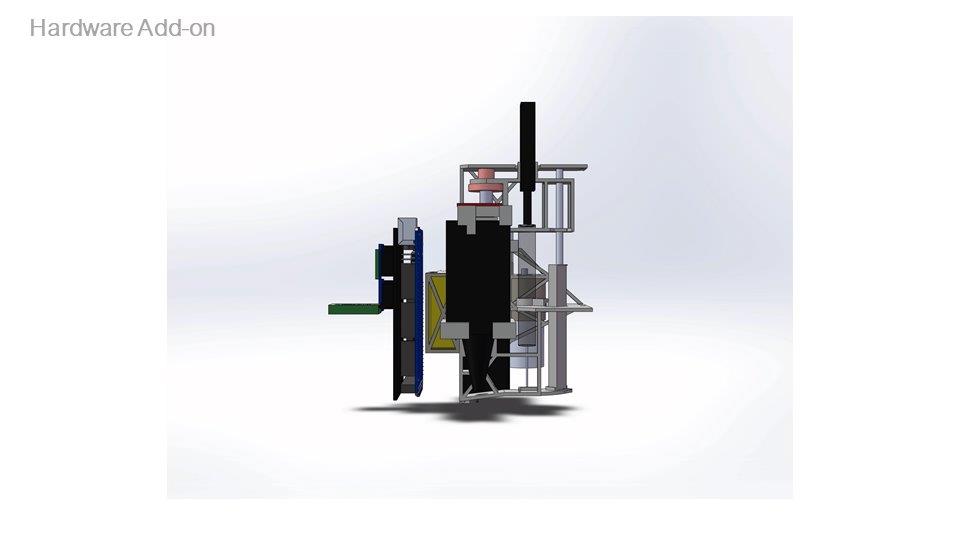

Hardware Add-on: Silver Dispenser and Pick-and-place Mechanism

We developed an add-on for a laser cutter that allows it to fabricate functional electromechanical devices. Our hardware add-on complements the laser cutter's native abilities to create the geometry of a device with circuit creation and assembly capabilities. We accomplish this by adding a silver dispenser and a pick-and-place mechanism to the laser cutter head (Figure 3).

Add-on Functionality: Circuit Trace Creation and Component Assembly

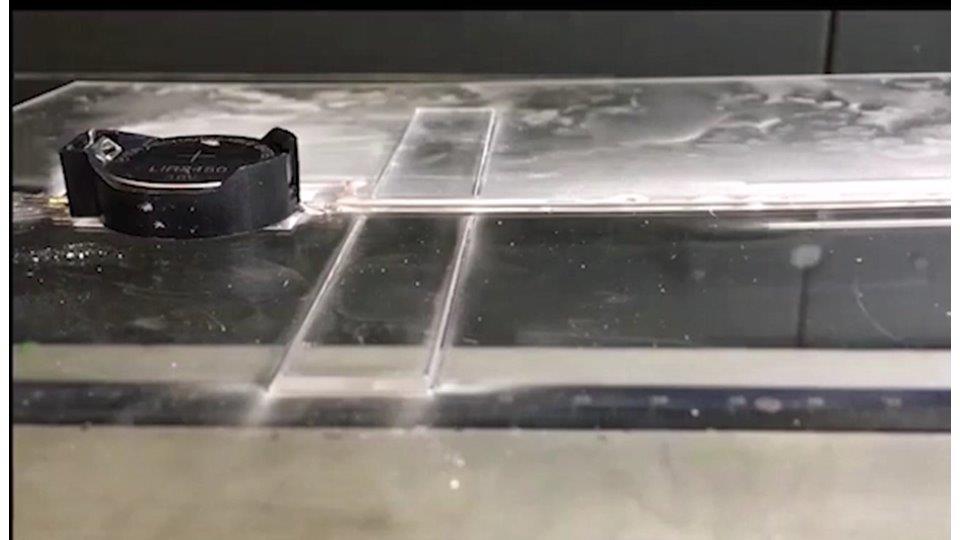

Our hardware add-on together with the laser cutter's native functionality creates functional devices in the following way: (1) To create the geometry, our system uses the regular laser cutter head to cut 2D geometries and optionally bend them into 3D using techniques, such as LaserOrigami [15]. (2) To add circuit traces, our silver dispenser in the form of a syringe extrudes silver paste. It can create highly conductive circuit traces (down to 3.2 Ohm/m) sufficient for most electronic components. (3) To assemble components, a pick-and-place mechanism consisting of a second syringe on the add-on enables moving components inside the laser cutter. Components are picked from a storage area within the laser cutter platform. Our add-on accommodates lifting components up to a mass of 65g and small SMD components down to size 2010. (4) Finally, we use laser soldering (explained in section 6) to cure the traces and make them conductive using the existing laser. The housing of the add-on was 3D-printed using an Ultimaker 3. With all onboard parts, the add-on weights 550g and costs $150 in parts.

Figure 2. Making a Device with LaserFactory: (a) Cutting the device geometry, (b) dispensing silver to form the circuit traces, (c) picking-and-placing the components, here a quadcopter’s rotor, and (d) curing the uncured silver traces. (e) When the last trace is cured, the device is fully functional; here, the quadcopter lifts directly off from the platform.

Hardware Add-on: Silver Dispenser and Pick-and-place Mechanism

We developed an add-on for a laser cutter that allows it to fabricate functional electromechanical devices. Our hardware add-on complements the laser cutter's native abilities to create the geometry of a device with circuit creation and assembly capabilities. We accomplish this by adding a silver dispenser and a pick-and-place mechanism to the laser cutter head (Figure 3).

Add-on Functionality: Circuit Trace Creation and Component Assembly

Our hardware add-on together with the laser cutter's native functionality creates functional devices in the following way: (1) To create the geometry, our system uses the regular laser cutter head to cut 2D geometries and optionally bend them into 3D using techniques, such as LaserOrigami [15]. (2) To add circuit traces, our silver dispenser in the form of a syringe extrudes silver paste. It can create highly conductive circuit traces (down to 3.2 Ohm/m) sufficient for most electronic components. (3) To assemble components, a pick-and-place mechanism consisting of a second syringe on the add-on enables moving components inside the laser cutter. Components are picked from a storage area within the laser cutter platform. Our add-on accommodates lifting components up to a mass of 65g and small SMD components down to size 2010. (4) Finally, we use laser soldering (explained in section 6) to cure the traces and make them conductive using the existing laser. The housing of the add-on was 3D-printed using an Ultimaker 3. With all onboard parts, the add-on weights 550g and costs $150 in parts.

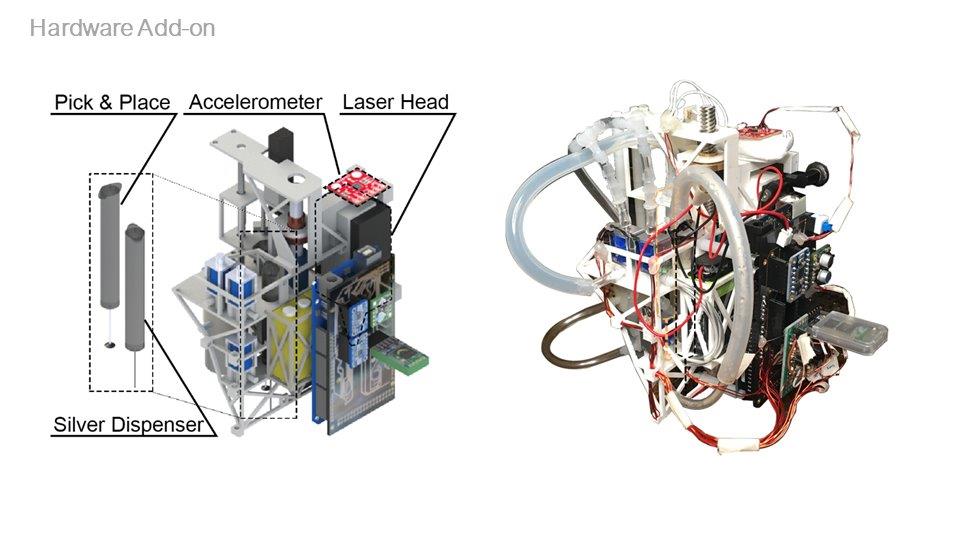

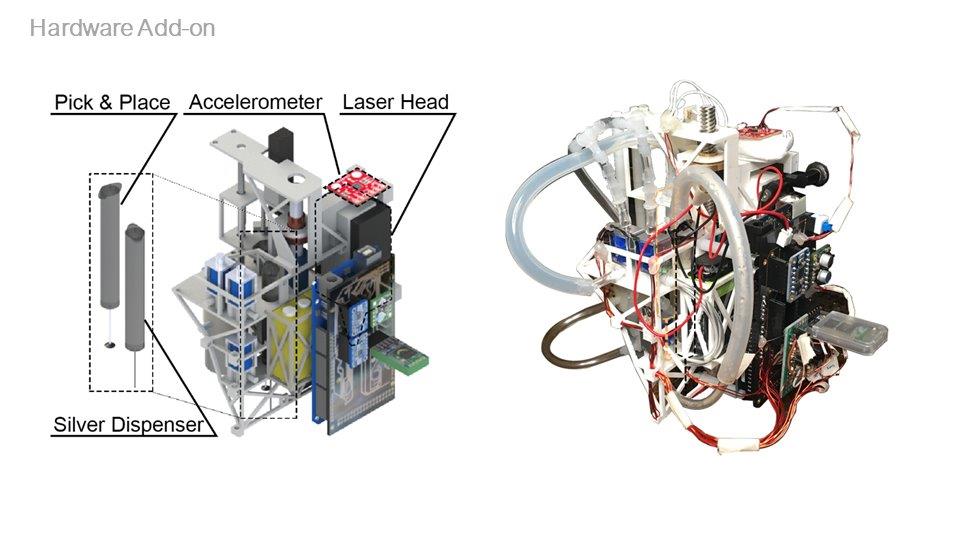

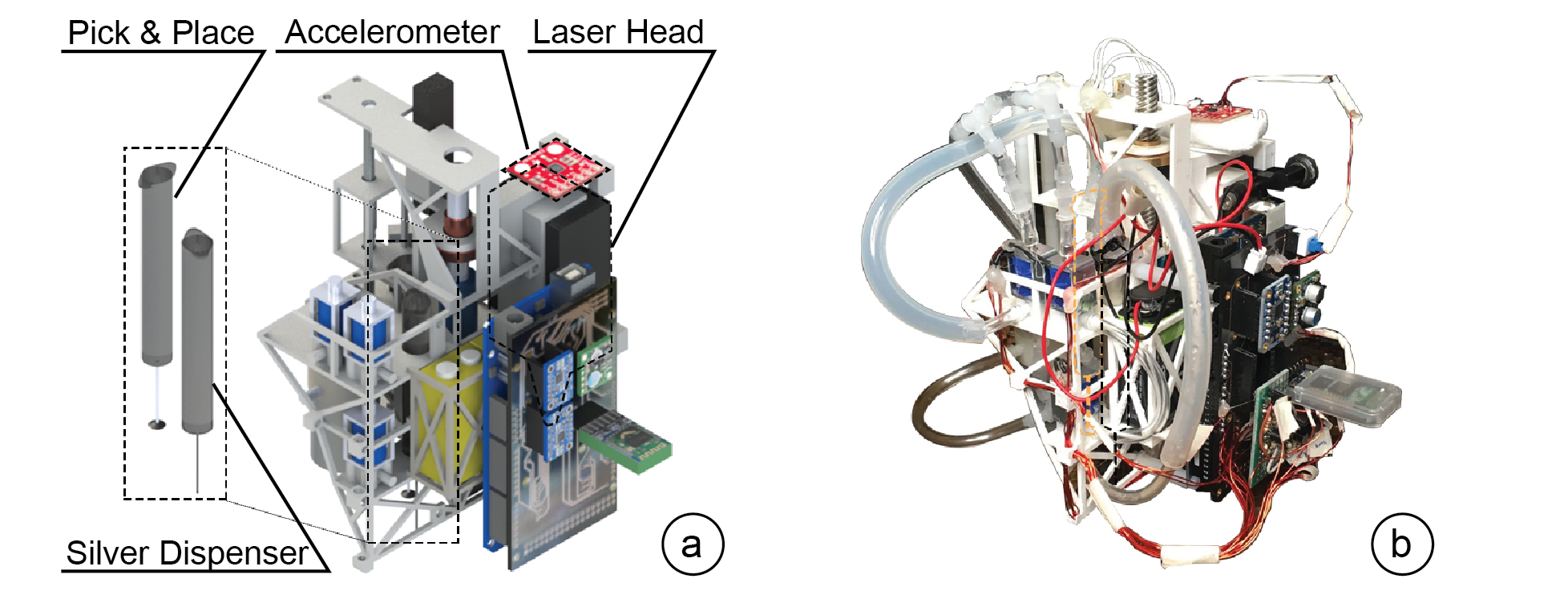

Figure 3. Our hardware add-on shown as (a) a CAD rendering and (b) a photo of the physical device. The add-on consists of a silver dispenser to create circuit traces and a pick-and-place mechanism to assemble electronic components. It attaches to the laser head, which is used to create the device's geometry and to cure the circuit traces. The image also shows the accelerometer used for detecting the motion signaling when the add-on should start/stop its operation.

Hardware Implementation

Pneumatic Actuation for Dispensing Silver and Picking/Placing Components: The add-on's silver extrusion and pick-and-place mechanisms are both actuated pneumatically. The silver extruder consists of a 3ml syringe tipped with a 18-gauge needle filled with silver paste. The pick-and-place includes a second 3ml syringe connected to a rubber-tipped 14-gauge needle. For both dispensing and pick-and-place, we use a single pneumatic pump (TCS Electrical, 6V-rated) that supports both mechanisms by regulating air supply via a network of three identical 3-port, 2-position solenoid valves (Phoncoo, 6V-rated).

Vertical Actuation for Picking-and-Placing Components from the Fabrication Bed: The pick-and-place syringe must travel vertically during its operation, descending to the fabrication bed to pick/place components, and ascending during traveling to avoid collisions with other components. The pick-and-place syringe is actuated vertically by a NEMA 14 stepper motor (StepperOnline) via a lead screw and rigid coupling, to which it is connected in serial via a spring-loaded linear potentiometer (Sensata 9600). This affords the pick-and-place mechanism the compliance required to avoid damage while allowing the controller software to evaluate the contact forces during component handling. It is also rigidly attached to a second linear potentiometer (BOURNS) which allows sensing of its height and thus distance to the material sheet in real-time.

Control Logic of Add-on: To enable the control logic for the add-on, we mounted a micro-controller (Arduino Mega 2560) onto the add-on and shielded it with a custom PCB that houses the supporting electronics required for the add-on. The supporting electronics include one motor driver (Adafruit DRV8833), one 6V buck regulator (Pololu D24V25F6), and the accelerometer (part of a Sparkfun LSM9DS1 IMU). To switch the pump between the silver dispensing syringe and the pick-and-place syringe, three parallel NPN transistors (2N2222) are used for overcurrent protection, each fitted with 1.5Ω series ballast resistors to avoid thermal runaway.

Technical Evaluation of Hardware Add-on

We evaluated both the silver deposition and pick-and-place capabilities to provide insight into which type of circuits can be created with LaserFactory.

Silver deposition trace characteristics: Since the needle gauge has a significant impact on the minimum trace width, we ran an experiment to determine the smallest needle gauge through which our 6V-rated pump could dispense silver. Smaller needle gauges require higher pressures to dispense the highly viscous silver. We found that by testing needle gauges from 14 to 21, that 18 was the highest gauge through which our 6V-rated pump was able to dispense silver. We then tested depositing this silver two ways. First, by depositing directly onto a material substrate, which facilitates rapid device fabrication but allows silver to spread across the substrate over time, increasing trace widths up to 3mm. As a second slower alternative, we engraved 0.75mm channels using a defocused laser and dispensed silver into these, yielding a minimum trace width of 0.75mm with our current setup. For the future, this trace width could be further reduced by using a stronger pump and narrower nozzle; Valentine et al. [29] for instance, use a 0.2mm nozzle with their platform.

After determining the minimum trace width, we also determined the minimum distance between two adjacent traces, which is important since it determines the pin spacing and thus the size of the components that can be used. To find the minimum trace distance between adjacent traces, we deposited and soldered parallel traces spaced between 0.4mm and 1.8mm apart in 0.2 mm increments. We found that the minimum distance was 0.8mm between traces for silver that had been appropriately refrigerated before use, as the silver's high viscosity and surface tension prevents it from spreading after it has been dispensed. However, for silver left at room temperature, 1.5mm was the minimum distance achievable with our chosen needle gauge. Smaller distances may cause short-circuits between adjacent traces due to the silver spreading across the substrate or ballooning slightly during laser curing. In addition, while our silver dispenser negatively pressurizes to de-ooze before moving between traces, it is not actuated in the z-axis and can therefore not retract from the substrate, leading to silver occasionally being spread between traces. This, however, does not cause short circuits or impact the device functionally since silver only becomes conductive where addressed by the laser which only targets the actual traces, thus the remaining silver can be wiped off. For future work, we plan to make the dispenser retractable to avoid additional spread. Based on these results, we conclude that we can currently create traces fine enough to work with SMD components down to a 1.55 mm pin spacing in ideal conditions where the silver was refrigerated before use, and 2.3mm when silver is at room temperature, which can be used for components with standard pin spacings of 2.54mm.

Pick and place component criteria: We evaluated the criteria under which LaserFactory can pick and place components. First, components require a minimum flat surface area of 3x3mm above the component’s center of mass for the suction tip's 2.5mm diameter nozzle to form a good contact. We found this could be increased or decreased by increasing or decreasing the diameter of the pick-and-place nozzle, respectively. Second, components must have a mass smaller than 65g for the pump suction to lift them. This threshold allows lifting large components, such as an Arduino Mega micro-controller (37g). A stronger pump could further raise this threshold. Third, their height cannot exceed 27 mm, currently limited by the maximum extension of the linear potentiometer used to assess picking height. Given these constraints, LaserFactory can pick large, heavy components, such as typical 3V batteries; tall components such as rotors; and a variety of small components, such as SMD resistors down to size 2010. For future work, these constraints can be further lifted by using a smaller nozzle, larger pump, and longer lead screw.

Use over time: During the course of fabrication, the peak power draw measured from the two on-board parallel 9V lithium ion batteries was 13.5W. Between no-load cases of cutting/folding and variable-load cases of PCB-making, this is sufficient for approximately 4 hours of continuous device creation. We detected no irregularities in laser carriage motion that would indicate undue stress on the laser cutter during use.

Laser soldering: Curing Circuit Traces using a CO2 laser

When both the silver paste has been deposited and the components have been placed onto a substrate in the laser cutter, the silver is not yet conductive, nor does it rigidly bond components to the substrate. For this, the silver requires curing via heating, traditionally achieved via baking the created device in an oven before it becomes functional. However, this has several drawbacks, such as that the heat in the oven can damage the material substrate and the electronic components due to the thermal stresses. To solve this issue, we developed a technique that uses the laser to cure the circuit traces and connect components electrically. A benefit of using the laser is that it allows for a fully integrated fabrication process with no manual work required. In addition, heat is only applied locally to traces and thus affects the material sheet only in the locations of the trace. Finally, using the laser is fast, approximately 5 minutes in contrast to the 2 hours achieved via uniform heating in an oven ~\cite{valentine2017hybrid}. Once the last circuit trace is cured, the device is functional right off the fabrication bed.

Fabrication Settings for Laser Soldering

We ran a set of experiments to determine the best power, speed, and z-axis settings for curing silver traces. For the experiments, we used a Universal Laser Systems ULS.PLS.150D laser cutter equipped with a 2.0 inch lens. For the silver, we used the silver paste from SunChemical (C2180423D2), which has a composition of 56.69% 24K silver and 43.31% a blend of resin and solvents.

Power/Speed/Height Settings: To find admissible laser cutter settings that successfully cured the silver, we dispensed a series of 100mm silver traces, then soldered them with different parameters. We first calibrated the vertical offset that produced a defocused laser spot diameter equal to trace width of silver. We then irradiated the silver using permutations of power and speed settings on the interval 0.2% to 90%, recording the resistance of the traces using a Greenlee DM-820A Multimeter and recording whether it was viscous (uncured), solid (cured), or burnt (overcured) to touch. We found numerous admissible power-speed combinations producing rigid, conductive traces. These are bounded by the combination of 0.2% speed with 7% power on the lower bound, and the combination of 7% speed with 90% power on the upper bound. Linear interpolation between these lower and upper bounds yield further admissible settings, showing that lower powers require commensurately lower speeds to effectively cure the silver. Power/speed ratios greater than this produce charred, brittle traces, while power/speed ratios lower than this leave the silver poorly conductive and uncured. In addition, high speeds above 7% produce traces that remain subcutaneously uncured regardless of power, while powers below 1% do not elevate temperatures sufficiently to cure traces at all.

Technical Evaluation of Laser Soldering

To determine the conductivity of traces cured via laser soldering and the soldering connection quality between traces and components, we ran the following technical evaluation.

Conductivity: To evaluate the conductivity that laser soldering achieves in a single pass of the laser, we fabricated 8 traces of length 0.5m and with a minimum trace width of 0.8mm. we then measured the resistance between the traces’ ends using a Multimeter (Greenlee DM-820A). The resistance was normally distributed about \SI{3.2}{\ohm}/m with a standard deviation of 0.0005. LaserFactory thus supports a range of electronic components, actuators, I2C communication, PWM, and medium to high-power applications.

Power and frequency: We used a current-limited power supply to pass DC current through five 100mm traces at 1A, 2A and 3A power without observing arcing or warming. In addition, we used a frequency generator to deliver an AC signal from 0Hz to 100kHz in logarithmic increments. Investigating the signal with an oscilloscope showed there was no significant signal attenuation.

Soldering connection quality of traces and components: To test how strong the cured connections between the traces and the components are, we evaluated their mechanical rigidity. We used a two-pad component and hung weights to the face of the component to apply normal forces between 25g and 300g in increments of 25g. We found that a normal force of 225g was required to disconnect the component from the trace. The strength of the curing connection is considerably less than that of a traditional solder connection. While this can be a drawback for devices that undergo high mechanical strain, it also has the benefit that components can be re-used, as users can pull them off with reasonable force.

Warping: Warping is a form of material distortion that can occur during laser cutting, and can arise from laser soldering too. This occurs due to rapid local temperature changes from selective heating of areas being targeted. The amount of warping is affected by both the choice of material and the part size, as heat cannot dissipate out of smaller parts via conduction.

To explore this, we tested its effect on three materials: extruded acrylic, and two cast acrylics (unbranded plexiglass). All were of equal transparency and thickness (1.5mm). While we observed no warping for the cast acrylic, we found that extruded acrylic did exhibit warping, and we calibrated our laser cutting settings to minimize its effects. Since some of our devices are made from extruded acrylic, this warping can be observed as a result of the laser soldering process in the accompanying video. While this distortion can impact both the visual appeal of devices as well as their operation if their function relies on precise planar surfaces, the effects can be largely avoided by using one of the alternative materials. In addition, we found that warping can be further reduced by cutting the device out in the final stage in the fabrication process instead of at the beginning, allowing the surrounding material to hold it in place during soldering. Alternatively, connector tabs can be left on the cut outline to achieve the same effect, i.e. keeping the device attached to the sheet during soldering, and cutting these tabs to release the device at the end.

Materials: We tested LaserFactory's compatibility with a range of materials, including extruded acrylic, cast acrylic, leather, cardboard, hardwood (oak) and plywood. Extruded and cast acrylics were compatible with the full LaserFactory suite, including the engraving of trace channels (section 4.3) and bending of the substrate (section 5.3) to create 2.5D geometries; however, extruded acrylic was prone to warping. The woods and and cardboard were also tested successfully, although these char visibly during soldering if the laser contacts the material directly. Furthermore, while not susceptible to warping, they cannot support bending or the engraving of trace channels. Lastly, leather and other soft textiles were not able to support the silver traces due to the traces cracking upon being bent after curing. This, however, can be addressed by attaching a firm backing to the soft material.

In summary, we conclude that laser soldering using a CO2 laser is suitable for creating highly conductive traces, that the soldering connection holds components in place while allowing components to be removed using manual force, and that warping due to laser-induced local heating only affects certain materials significantly.

Creating Non-planar Geometries

In this section, we report on two proof-of-concepts that showcase different methods of creating non-planar geometries using LaserFactory.

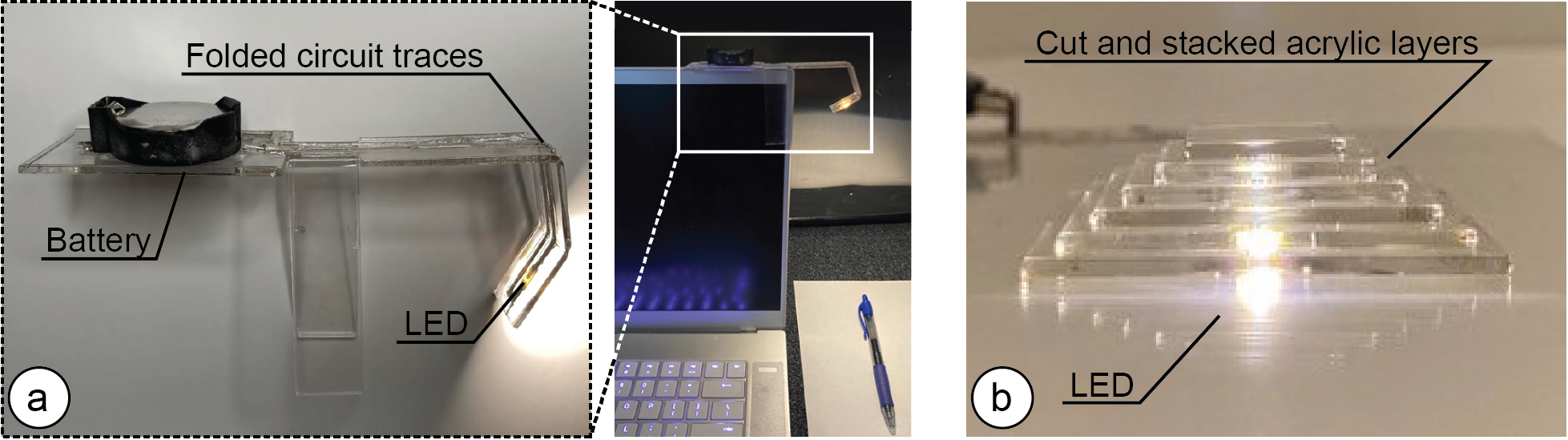

Laser Soldering Folded 2.5D Circuit Traces: Since our technique is built based on a laser cutter, which has been shown to not only be able to create 2D geometries but also 3D geometries via folding (LaserOrigami [15]), we also investigated if we can dispense and cure circuit traces that are positioned across a fold, which would allow LaserFactory to fabricate 2.5D geometries with embedded traces and electronics (Figure 4a). Our early experiments showed that by using the laser to slowly heat traces across a hinge, the silver remains viscous and uncured, which allows the substrate to become compliant and fold under its own gravity. By continuing the heating process after folding, the silver gradually cures and hardens, producing 2.5D geometries with embedded traces. While we did not evaluate the different power/speed settings in a controlled experiment, we did not observe a difference in resistance between folded and planar traces. We include the associated laser settings in Table 1.

Figure 3. Our hardware add-on shown as (a) a CAD rendering and (b) a photo of the physical device. The add-on consists of a silver dispenser to create circuit traces and a pick-and-place mechanism to assemble electronic components. It attaches to the laser head, which is used to create the device's geometry and to cure the circuit traces. The image also shows the accelerometer used for detecting the motion signaling when the add-on should start/stop its operation.

Hardware Implementation

Pneumatic Actuation for Dispensing Silver and Picking/Placing Components: The add-on's silver extrusion and pick-and-place mechanisms are both actuated pneumatically. The silver extruder consists of a 3ml syringe tipped with a 18-gauge needle filled with silver paste. The pick-and-place includes a second 3ml syringe connected to a rubber-tipped 14-gauge needle. For both dispensing and pick-and-place, we use a single pneumatic pump (TCS Electrical, 6V-rated) that supports both mechanisms by regulating air supply via a network of three identical 3-port, 2-position solenoid valves (Phoncoo, 6V-rated).

Vertical Actuation for Picking-and-Placing Components from the Fabrication Bed: The pick-and-place syringe must travel vertically during its operation, descending to the fabrication bed to pick/place components, and ascending during traveling to avoid collisions with other components. The pick-and-place syringe is actuated vertically by a NEMA 14 stepper motor (StepperOnline) via a lead screw and rigid coupling, to which it is connected in serial via a spring-loaded linear potentiometer (Sensata 9600). This affords the pick-and-place mechanism the compliance required to avoid damage while allowing the controller software to evaluate the contact forces during component handling. It is also rigidly attached to a second linear potentiometer (BOURNS) which allows sensing of its height and thus distance to the material sheet in real-time.

Control Logic of Add-on: To enable the control logic for the add-on, we mounted a micro-controller (Arduino Mega 2560) onto the add-on and shielded it with a custom PCB that houses the supporting electronics required for the add-on. The supporting electronics include one motor driver (Adafruit DRV8833), one 6V buck regulator (Pololu D24V25F6), and the accelerometer (part of a Sparkfun LSM9DS1 IMU). To switch the pump between the silver dispensing syringe and the pick-and-place syringe, three parallel NPN transistors (2N2222) are used for overcurrent protection, each fitted with 1.5Ω series ballast resistors to avoid thermal runaway.

Technical Evaluation of Hardware Add-on

We evaluated both the silver deposition and pick-and-place capabilities to provide insight into which type of circuits can be created with LaserFactory.

Silver deposition trace characteristics: Since the needle gauge has a significant impact on the minimum trace width, we ran an experiment to determine the smallest needle gauge through which our 6V-rated pump could dispense silver. Smaller needle gauges require higher pressures to dispense the highly viscous silver. We found that by testing needle gauges from 14 to 21, that 18 was the highest gauge through which our 6V-rated pump was able to dispense silver. We then tested depositing this silver two ways. First, by depositing directly onto a material substrate, which facilitates rapid device fabrication but allows silver to spread across the substrate over time, increasing trace widths up to 3mm. As a second slower alternative, we engraved 0.75mm channels using a defocused laser and dispensed silver into these, yielding a minimum trace width of 0.75mm with our current setup. For the future, this trace width could be further reduced by using a stronger pump and narrower nozzle; Valentine et al. [29] for instance, use a 0.2mm nozzle with their platform.

After determining the minimum trace width, we also determined the minimum distance between two adjacent traces, which is important since it determines the pin spacing and thus the size of the components that can be used. To find the minimum trace distance between adjacent traces, we deposited and soldered parallel traces spaced between 0.4mm and 1.8mm apart in 0.2 mm increments. We found that the minimum distance was 0.8mm between traces for silver that had been appropriately refrigerated before use, as the silver's high viscosity and surface tension prevents it from spreading after it has been dispensed. However, for silver left at room temperature, 1.5mm was the minimum distance achievable with our chosen needle gauge. Smaller distances may cause short-circuits between adjacent traces due to the silver spreading across the substrate or ballooning slightly during laser curing. In addition, while our silver dispenser negatively pressurizes to de-ooze before moving between traces, it is not actuated in the z-axis and can therefore not retract from the substrate, leading to silver occasionally being spread between traces. This, however, does not cause short circuits or impact the device functionally since silver only becomes conductive where addressed by the laser which only targets the actual traces, thus the remaining silver can be wiped off. For future work, we plan to make the dispenser retractable to avoid additional spread. Based on these results, we conclude that we can currently create traces fine enough to work with SMD components down to a 1.55 mm pin spacing in ideal conditions where the silver was refrigerated before use, and 2.3mm when silver is at room temperature, which can be used for components with standard pin spacings of 2.54mm.

Pick and place component criteria: We evaluated the criteria under which LaserFactory can pick and place components. First, components require a minimum flat surface area of 3x3mm above the component’s center of mass for the suction tip's 2.5mm diameter nozzle to form a good contact. We found this could be increased or decreased by increasing or decreasing the diameter of the pick-and-place nozzle, respectively. Second, components must have a mass smaller than 65g for the pump suction to lift them. This threshold allows lifting large components, such as an Arduino Mega micro-controller (37g). A stronger pump could further raise this threshold. Third, their height cannot exceed 27 mm, currently limited by the maximum extension of the linear potentiometer used to assess picking height. Given these constraints, LaserFactory can pick large, heavy components, such as typical 3V batteries; tall components such as rotors; and a variety of small components, such as SMD resistors down to size 2010. For future work, these constraints can be further lifted by using a smaller nozzle, larger pump, and longer lead screw.

Use over time: During the course of fabrication, the peak power draw measured from the two on-board parallel 9V lithium ion batteries was 13.5W. Between no-load cases of cutting/folding and variable-load cases of PCB-making, this is sufficient for approximately 4 hours of continuous device creation. We detected no irregularities in laser carriage motion that would indicate undue stress on the laser cutter during use.

Laser soldering: Curing Circuit Traces using a CO2 laser

When both the silver paste has been deposited and the components have been placed onto a substrate in the laser cutter, the silver is not yet conductive, nor does it rigidly bond components to the substrate. For this, the silver requires curing via heating, traditionally achieved via baking the created device in an oven before it becomes functional. However, this has several drawbacks, such as that the heat in the oven can damage the material substrate and the electronic components due to the thermal stresses. To solve this issue, we developed a technique that uses the laser to cure the circuit traces and connect components electrically. A benefit of using the laser is that it allows for a fully integrated fabrication process with no manual work required. In addition, heat is only applied locally to traces and thus affects the material sheet only in the locations of the trace. Finally, using the laser is fast, approximately 5 minutes in contrast to the 2 hours achieved via uniform heating in an oven ~\cite{valentine2017hybrid}. Once the last circuit trace is cured, the device is functional right off the fabrication bed.

Fabrication Settings for Laser Soldering

We ran a set of experiments to determine the best power, speed, and z-axis settings for curing silver traces. For the experiments, we used a Universal Laser Systems ULS.PLS.150D laser cutter equipped with a 2.0 inch lens. For the silver, we used the silver paste from SunChemical (C2180423D2), which has a composition of 56.69% 24K silver and 43.31% a blend of resin and solvents.

Power/Speed/Height Settings: To find admissible laser cutter settings that successfully cured the silver, we dispensed a series of 100mm silver traces, then soldered them with different parameters. We first calibrated the vertical offset that produced a defocused laser spot diameter equal to trace width of silver. We then irradiated the silver using permutations of power and speed settings on the interval 0.2% to 90%, recording the resistance of the traces using a Greenlee DM-820A Multimeter and recording whether it was viscous (uncured), solid (cured), or burnt (overcured) to touch. We found numerous admissible power-speed combinations producing rigid, conductive traces. These are bounded by the combination of 0.2% speed with 7% power on the lower bound, and the combination of 7% speed with 90% power on the upper bound. Linear interpolation between these lower and upper bounds yield further admissible settings, showing that lower powers require commensurately lower speeds to effectively cure the silver. Power/speed ratios greater than this produce charred, brittle traces, while power/speed ratios lower than this leave the silver poorly conductive and uncured. In addition, high speeds above 7% produce traces that remain subcutaneously uncured regardless of power, while powers below 1% do not elevate temperatures sufficiently to cure traces at all.

Technical Evaluation of Laser Soldering

To determine the conductivity of traces cured via laser soldering and the soldering connection quality between traces and components, we ran the following technical evaluation.

Conductivity: To evaluate the conductivity that laser soldering achieves in a single pass of the laser, we fabricated 8 traces of length 0.5m and with a minimum trace width of 0.8mm. we then measured the resistance between the traces’ ends using a Multimeter (Greenlee DM-820A). The resistance was normally distributed about \SI{3.2}{\ohm}/m with a standard deviation of 0.0005. LaserFactory thus supports a range of electronic components, actuators, I2C communication, PWM, and medium to high-power applications.

Power and frequency: We used a current-limited power supply to pass DC current through five 100mm traces at 1A, 2A and 3A power without observing arcing or warming. In addition, we used a frequency generator to deliver an AC signal from 0Hz to 100kHz in logarithmic increments. Investigating the signal with an oscilloscope showed there was no significant signal attenuation.

Soldering connection quality of traces and components: To test how strong the cured connections between the traces and the components are, we evaluated their mechanical rigidity. We used a two-pad component and hung weights to the face of the component to apply normal forces between 25g and 300g in increments of 25g. We found that a normal force of 225g was required to disconnect the component from the trace. The strength of the curing connection is considerably less than that of a traditional solder connection. While this can be a drawback for devices that undergo high mechanical strain, it also has the benefit that components can be re-used, as users can pull them off with reasonable force.

Warping: Warping is a form of material distortion that can occur during laser cutting, and can arise from laser soldering too. This occurs due to rapid local temperature changes from selective heating of areas being targeted. The amount of warping is affected by both the choice of material and the part size, as heat cannot dissipate out of smaller parts via conduction.

To explore this, we tested its effect on three materials: extruded acrylic, and two cast acrylics (unbranded plexiglass). All were of equal transparency and thickness (1.5mm). While we observed no warping for the cast acrylic, we found that extruded acrylic did exhibit warping, and we calibrated our laser cutting settings to minimize its effects. Since some of our devices are made from extruded acrylic, this warping can be observed as a result of the laser soldering process in the accompanying video. While this distortion can impact both the visual appeal of devices as well as their operation if their function relies on precise planar surfaces, the effects can be largely avoided by using one of the alternative materials. In addition, we found that warping can be further reduced by cutting the device out in the final stage in the fabrication process instead of at the beginning, allowing the surrounding material to hold it in place during soldering. Alternatively, connector tabs can be left on the cut outline to achieve the same effect, i.e. keeping the device attached to the sheet during soldering, and cutting these tabs to release the device at the end.

Materials: We tested LaserFactory's compatibility with a range of materials, including extruded acrylic, cast acrylic, leather, cardboard, hardwood (oak) and plywood. Extruded and cast acrylics were compatible with the full LaserFactory suite, including the engraving of trace channels (section 4.3) and bending of the substrate (section 5.3) to create 2.5D geometries; however, extruded acrylic was prone to warping. The woods and and cardboard were also tested successfully, although these char visibly during soldering if the laser contacts the material directly. Furthermore, while not susceptible to warping, they cannot support bending or the engraving of trace channels. Lastly, leather and other soft textiles were not able to support the silver traces due to the traces cracking upon being bent after curing. This, however, can be addressed by attaching a firm backing to the soft material.

In summary, we conclude that laser soldering using a CO2 laser is suitable for creating highly conductive traces, that the soldering connection holds components in place while allowing components to be removed using manual force, and that warping due to laser-induced local heating only affects certain materials significantly.

Creating Non-planar Geometries

In this section, we report on two proof-of-concepts that showcase different methods of creating non-planar geometries using LaserFactory.

Laser Soldering Folded 2.5D Circuit Traces: Since our technique is built based on a laser cutter, which has been shown to not only be able to create 2D geometries but also 3D geometries via folding (LaserOrigami [15]), we also investigated if we can dispense and cure circuit traces that are positioned across a fold, which would allow LaserFactory to fabricate 2.5D geometries with embedded traces and electronics (Figure 4a). Our early experiments showed that by using the laser to slowly heat traces across a hinge, the silver remains viscous and uncured, which allows the substrate to become compliant and fold under its own gravity. By continuing the heating process after folding, the silver gradually cures and hardens, producing 2.5D geometries with embedded traces. While we did not evaluate the different power/speed settings in a controlled experiment, we did not observe a difference in resistance between folded and planar traces. We include the associated laser settings in Table 1.

Figure 4. LaserFactory can be used to create (a) 2.5D geometries via folding, (b) as well as discretized 3D geometries via cutting and pick-and-placing the material substrate itself.

Cutting and stacking layerwise 3D structures: In addition to folding 2.5D traces, we report on a second method of creating 3D geometries that leverages the unique combination of our pick-and-place mechanism with a laser cutter. In addition to placing electrical components on a device, we can also pick-and-place pieces of the material substrate. To harvest these pieces, shapes are first cut from the substrate and then the pick-and-place is used to stack them to create 3D structures (Figure 4b). By discretizing a structure into layers, these layers can be cut using a focused laser, stacked via pick-and-place, and welded using a defocused laser [27] to produce rigid 3D structures without manual intervention.

Table 1. Fabrication settings. Columns, from left to right, show (a) process order (b) line manipulations, (c) laser cutter settings, (d) add-on settings for the silver dispenser and pick-and-place mechanism. A tilde indicates varying a value.

Figure 4. LaserFactory can be used to create (a) 2.5D geometries via folding, (b) as well as discretized 3D geometries via cutting and pick-and-placing the material substrate itself.

Cutting and stacking layerwise 3D structures: In addition to folding 2.5D traces, we report on a second method of creating 3D geometries that leverages the unique combination of our pick-and-place mechanism with a laser cutter. In addition to placing electrical components on a device, we can also pick-and-place pieces of the material substrate. To harvest these pieces, shapes are first cut from the substrate and then the pick-and-place is used to stack them to create 3D structures (Figure 4b). By discretizing a structure into layers, these layers can be cut using a focused laser, stacked via pick-and-place, and welded using a defocused laser [27] to produce rigid 3D structures without manual intervention.

Table 1. Fabrication settings. Columns, from left to right, show (a) process order (b) line manipulations, (c) laser cutter settings, (d) add-on settings for the silver dispenser and pick-and-place mechanism. A tilde indicates varying a value.

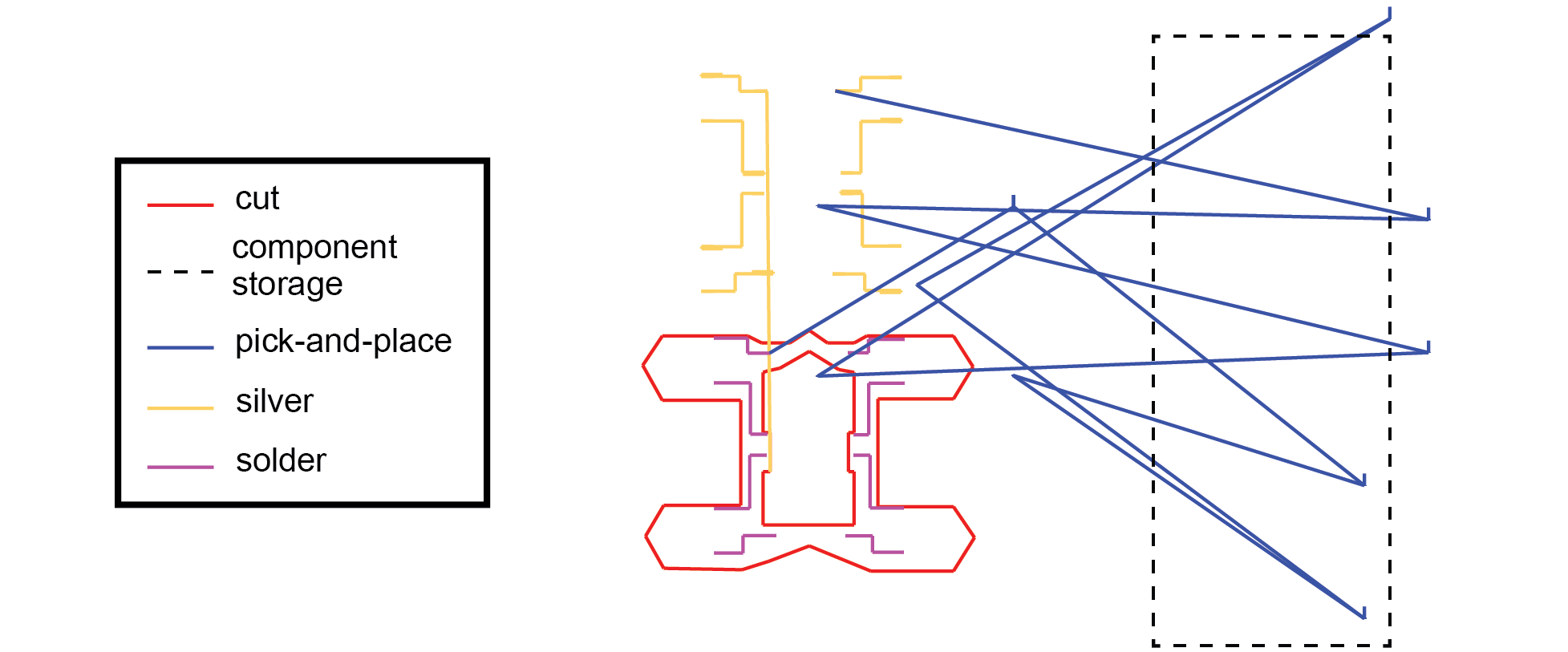

Figure 5. Adding lines to the design file to create additional carriage motion for pick-and-place operations, silver dispensing, and soldering. Lines are offset to compensate for each add-on part's position with respect to the laser head.

On the other hand, an accelerometer affixed to the laser head measures only its inertial motion in terms of acceleration, which makes it possible to recreate on other platforms. By appending a unique line pattern to the beginning and end of paths in the fabrication file, we elicit a specific motion from the laser head, which the onboard accelerometer interprets in order to start or stop a fabrication procedure (silver deposition or pick-and-place).

Motion Pattern Shape: To select a motion pattern for our signal, we investigated the motion of different shapes. In particular, we considered the motion of straight lines, squares and circles in order to test independent, sequential, and simultaneous motions in the X-Y plane, respectively. While all candidates yielded a uniquely classifiable signal, we found that squares and circles were unsuitable as performing their motions may cause extrusion of silver outside of a trace or collision with other components. A one-dimensional line that programmatically tracks backward along a previously deposited trace, in contrast, provides a trajectory that keeps the tip and any dispensed silver above traces.

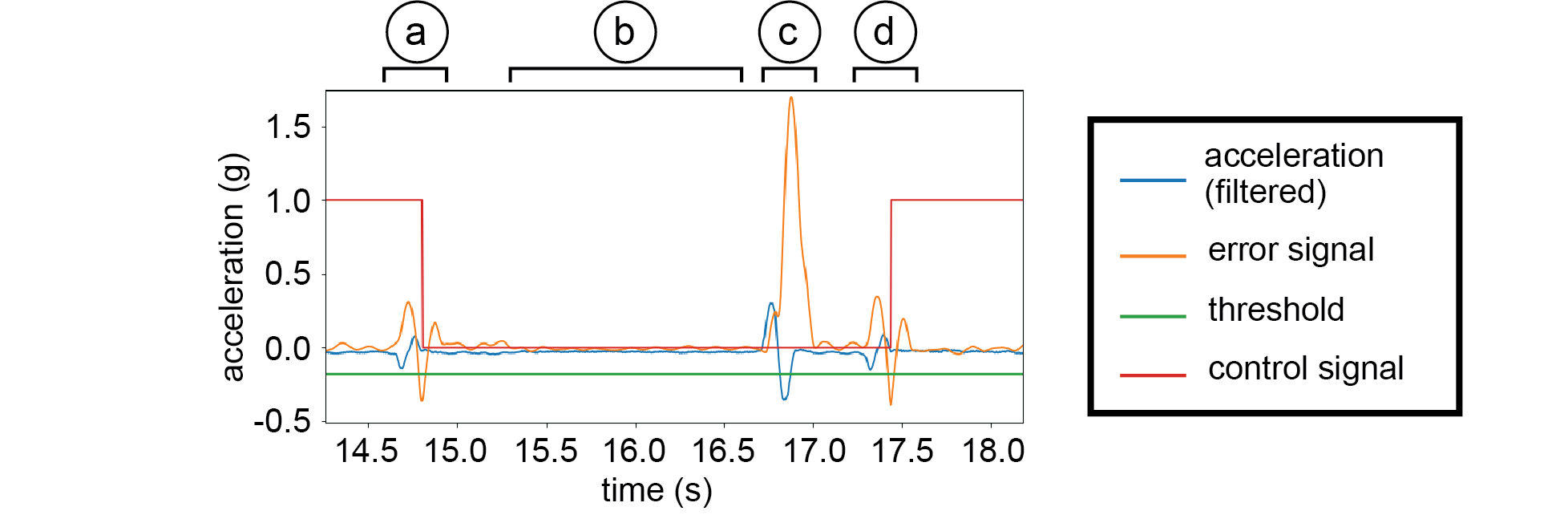

Duration of Line Pattern: The motion pattern's duration, and therefore physical length, must be small enough to be quickly evaluated by the classifier to allow rapid transmission of fabrication instructions yet long enough for the digital sampling to produce sufficiently many data points for the classifier. We tested the execution of straight lines of lengths between 0.5mm - 6mm in 0.5mm increments, measuring the duration of each. For our processor's maximum sampling speed of 300 Hz, 3mm lines constituted the fastest signal (150ms) that had a sufficient number of data points (45 samples) to encode a uniquely identifiable signal. By accelerating along the trace for 3mm, then decelerating to stop, the signal elicits two consecutive equal but opposite spikes on the accelerometer. This creates a unique signal, as no other maneuver requires re-tracing the exact same path, that can be reliably classified using the accelerometer (Figure 6).

% (Figure 6).

One-time signal calibration and Real-Time Classification

To build the classifier, we perform a one-time calibration of the 3mm line signal described above. We perform this calibration by executing the pattern and measuring the corresponding linear accelerations from the accelerometer in the X-Y plane. We sample the pattern at 300 Hz and low-pass filter it using a 24-point averaging filter to remove noise to construct the signal template.

Figure 5. Adding lines to the design file to create additional carriage motion for pick-and-place operations, silver dispensing, and soldering. Lines are offset to compensate for each add-on part's position with respect to the laser head.

On the other hand, an accelerometer affixed to the laser head measures only its inertial motion in terms of acceleration, which makes it possible to recreate on other platforms. By appending a unique line pattern to the beginning and end of paths in the fabrication file, we elicit a specific motion from the laser head, which the onboard accelerometer interprets in order to start or stop a fabrication procedure (silver deposition or pick-and-place).

Motion Pattern Shape: To select a motion pattern for our signal, we investigated the motion of different shapes. In particular, we considered the motion of straight lines, squares and circles in order to test independent, sequential, and simultaneous motions in the X-Y plane, respectively. While all candidates yielded a uniquely classifiable signal, we found that squares and circles were unsuitable as performing their motions may cause extrusion of silver outside of a trace or collision with other components. A one-dimensional line that programmatically tracks backward along a previously deposited trace, in contrast, provides a trajectory that keeps the tip and any dispensed silver above traces.

Duration of Line Pattern: The motion pattern's duration, and therefore physical length, must be small enough to be quickly evaluated by the classifier to allow rapid transmission of fabrication instructions yet long enough for the digital sampling to produce sufficiently many data points for the classifier. We tested the execution of straight lines of lengths between 0.5mm - 6mm in 0.5mm increments, measuring the duration of each. For our processor's maximum sampling speed of 300 Hz, 3mm lines constituted the fastest signal (150ms) that had a sufficient number of data points (45 samples) to encode a uniquely identifiable signal. By accelerating along the trace for 3mm, then decelerating to stop, the signal elicits two consecutive equal but opposite spikes on the accelerometer. This creates a unique signal, as no other maneuver requires re-tracing the exact same path, that can be reliably classified using the accelerometer (Figure 6).

% (Figure 6).

One-time signal calibration and Real-Time Classification

To build the classifier, we perform a one-time calibration of the 3mm line signal described above. We perform this calibration by executing the pattern and measuring the corresponding linear accelerations from the accelerometer in the X-Y plane. We sample the pattern at 300 Hz and low-pass filter it using a 24-point averaging filter to remove noise to construct the signal template.

Figure 6. Filtered accelerometer data during execution of the embedded pattern. When the pattern is executed, the (blue) acceleration produces oppositely signed spikes in rapid succession. (a,d) This characterized template causes the (orange) error signal to drop below the (green) threshold which flips the control signal to start/stop a command; here, starting/stopping the silver extrusion. (b) Periods of constant velocity are marked by accelerations around 0; (c) volatile maneuvers such as moving between contiguous traces causes large errors and thus can be differentiated from actual motion-signal instructions embedded in the fabrication file.

To choose the error signal threshold to identify a signal, we built a dataset of true positives by sampling the signal pattern 100 times, recording the maximum negative error produced by the matched filter for each. Equivalently, we built a dataset of true negatives, compiling a further 100 measurements taken during manoeuvres not associated with a signal. Modeling each as a normal distribution N (μ,σ2), we found the mean and standard deviation for the true positives (X) and true negatives (Z) were X~N(-0.311,0.002) and Z~N(0.057,0.008) respectively and choose our threshold at the intersection of these curves (-0.18) in order to minimize misfirings (false positives and negatives).

After the one-time calibration, our add-on is ready for real-time detection of the motion signals embedded in the design file. For the real-time detection, we low-pass filter the raw acceleration data using a 24-point averaging filter and save it into a 45-point circular buffer. We then build a matched filter by evaluating this buffer against the signal template using the L2 norm at 300 Hz. This produces an error signal of the low-pass filtered data that our detection algorithm normalizes around 0. We then continuously evaluate the output of the matched filter and signal an instruction to the silver extruder or pick-and-place mechanism when the error signal surpasses a characterized threshold.

Technical Evaluation of the Motion-Based Classifier

We evaluate both how reliable our motion-based classifier can detect the motion-signals and if the motion-based classification approach transfers across different fabrication machines.

Performance: First, we evaluated the accuracy with which our motion-based classifier detects signals embedded in the fabrication file. To determine this, we mounted the add-on to the laser head, then started fabrication of a design consisting of 5 horizontal lines and 5 vertical lines, each 50mm in length, totalling a combined 10 start signals and 10 stop signals (20 signals in total). For each signal, we noted whether detection was successful, and after all lines were executed, we dismounted the add-on. We repeated this procedure 10 times, for a total of 200 signals. One signal was undetected, yielding a classification accuracy of 99.5\% for this test, with 0 false positives, and 1 false negative. We then executed fabrication of our three application examples; the quadcopter, wristband, and PCB, five times each. These consist of a total of 465 signals, including 305 silver deposition sequences between 7mm and 90mm in length, and 115 pick-and-place sequences between 140 and 190mm in length. No signal misfirings were registered during these trials. By integrating the cumulative distribution functions of our normal distributions from Section 6 to evaluate the Receiver Operating Characteristic (ROC) curve for our characterized classification threshold, we find that our model predicts a false positive rate of approximately 0.2\% and false negative rate of 0.1\%, which agrees with these results. This result shows that our procedure produces a reliable classification due to our ability to freely design a unique signal for detection. However, in case the detection misfires, LaserFactory currently has no way to detect it. We plan to explore such detection as part of future work by embedding additional lines that function as interrupts.

Transferability: We designed the hardware add-on to be fully self-contained and the fabrication signaling to be motion-based in order to demonstrate an add-on design that can be used to augment different fabrication machines. To test if our add-on can indeed work on different fabrication machines, we tested our approach on the 3D printer Ultimaker 3. To conduct this test, we wrote a custom G-code script that mimicks silver deposition by executing first a vertical then a horizontal 30mm line, with our 3mm signal pattern appended at every line end. We use the G0 command to execute the pattern, representing a co-ordinated movement at rapid rate without material extrusion with feed rate set to F15000. We deployed this file 10 times on the Ultimaker 3 and achieved a 100\% signal classification accuracy. While additional tests on other fabrication devices are needed before full transferability can be claimed, the results show that motion-based signaling has the potential to work across different fabrication devices. Before motion-based signaling can be used on a new machine, the motion-signal must first be characterized via the one-time calibration and the add-on's physical clips need to be adjusted to the differently shaped tool head.

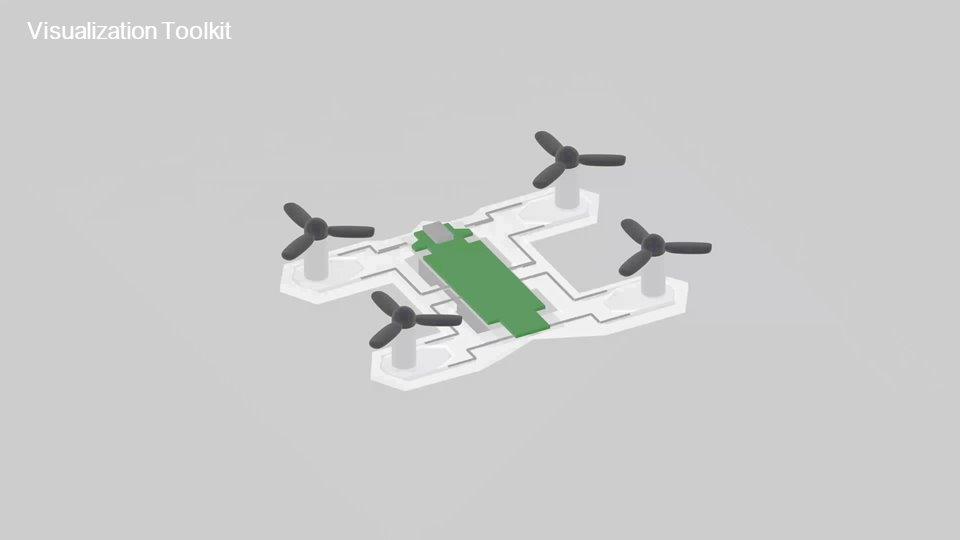

Designing a Device for Use with LaserFactory

To support the creation of devices with LaserFactory, we provide the end-to-end fabrication pipeline shown in Figure 7. It consists of a design and visualization tool as well as a post-processing script that converts the design file into a set of machine instructions for fabricating the device with LaserFactory on the augmented laser cutter. The design tool lets users create 2D designs using drawing tools for the geometry (‘cut’, ‘fold’), the circuit traces (‘wire’), and for placing electronic components (‘place part’). This allows users to concurrently design the geometry and the electronic circuit. The accompanying visualization tool renders both the final 2D or 3D design and allows users to animate each step of the fabrication process. This assists users who may find it difficult to visualize the abstract 2D drawing. In addition, it allows users to inspect the order of each step in the fabrication process. On export, our post-processing script automatically translates the design file into machine instructions. Users do not have to add any explicit instructions for the add-on.

Figure 6. Filtered accelerometer data during execution of the embedded pattern. When the pattern is executed, the (blue) acceleration produces oppositely signed spikes in rapid succession. (a,d) This characterized template causes the (orange) error signal to drop below the (green) threshold which flips the control signal to start/stop a command; here, starting/stopping the silver extrusion. (b) Periods of constant velocity are marked by accelerations around 0; (c) volatile maneuvers such as moving between contiguous traces causes large errors and thus can be differentiated from actual motion-signal instructions embedded in the fabrication file.

To choose the error signal threshold to identify a signal, we built a dataset of true positives by sampling the signal pattern 100 times, recording the maximum negative error produced by the matched filter for each. Equivalently, we built a dataset of true negatives, compiling a further 100 measurements taken during manoeuvres not associated with a signal. Modeling each as a normal distribution N (μ,σ2), we found the mean and standard deviation for the true positives (X) and true negatives (Z) were X~N(-0.311,0.002) and Z~N(0.057,0.008) respectively and choose our threshold at the intersection of these curves (-0.18) in order to minimize misfirings (false positives and negatives).

After the one-time calibration, our add-on is ready for real-time detection of the motion signals embedded in the design file. For the real-time detection, we low-pass filter the raw acceleration data using a 24-point averaging filter and save it into a 45-point circular buffer. We then build a matched filter by evaluating this buffer against the signal template using the L2 norm at 300 Hz. This produces an error signal of the low-pass filtered data that our detection algorithm normalizes around 0. We then continuously evaluate the output of the matched filter and signal an instruction to the silver extruder or pick-and-place mechanism when the error signal surpasses a characterized threshold.

Technical Evaluation of the Motion-Based Classifier

We evaluate both how reliable our motion-based classifier can detect the motion-signals and if the motion-based classification approach transfers across different fabrication machines.

Performance: First, we evaluated the accuracy with which our motion-based classifier detects signals embedded in the fabrication file. To determine this, we mounted the add-on to the laser head, then started fabrication of a design consisting of 5 horizontal lines and 5 vertical lines, each 50mm in length, totalling a combined 10 start signals and 10 stop signals (20 signals in total). For each signal, we noted whether detection was successful, and after all lines were executed, we dismounted the add-on. We repeated this procedure 10 times, for a total of 200 signals. One signal was undetected, yielding a classification accuracy of 99.5\% for this test, with 0 false positives, and 1 false negative. We then executed fabrication of our three application examples; the quadcopter, wristband, and PCB, five times each. These consist of a total of 465 signals, including 305 silver deposition sequences between 7mm and 90mm in length, and 115 pick-and-place sequences between 140 and 190mm in length. No signal misfirings were registered during these trials. By integrating the cumulative distribution functions of our normal distributions from Section 6 to evaluate the Receiver Operating Characteristic (ROC) curve for our characterized classification threshold, we find that our model predicts a false positive rate of approximately 0.2\% and false negative rate of 0.1\%, which agrees with these results. This result shows that our procedure produces a reliable classification due to our ability to freely design a unique signal for detection. However, in case the detection misfires, LaserFactory currently has no way to detect it. We plan to explore such detection as part of future work by embedding additional lines that function as interrupts.

Transferability: We designed the hardware add-on to be fully self-contained and the fabrication signaling to be motion-based in order to demonstrate an add-on design that can be used to augment different fabrication machines. To test if our add-on can indeed work on different fabrication machines, we tested our approach on the 3D printer Ultimaker 3. To conduct this test, we wrote a custom G-code script that mimicks silver deposition by executing first a vertical then a horizontal 30mm line, with our 3mm signal pattern appended at every line end. We use the G0 command to execute the pattern, representing a co-ordinated movement at rapid rate without material extrusion with feed rate set to F15000. We deployed this file 10 times on the Ultimaker 3 and achieved a 100\% signal classification accuracy. While additional tests on other fabrication devices are needed before full transferability can be claimed, the results show that motion-based signaling has the potential to work across different fabrication devices. Before motion-based signaling can be used on a new machine, the motion-signal must first be characterized via the one-time calibration and the add-on's physical clips need to be adjusted to the differently shaped tool head.

Designing a Device for Use with LaserFactory

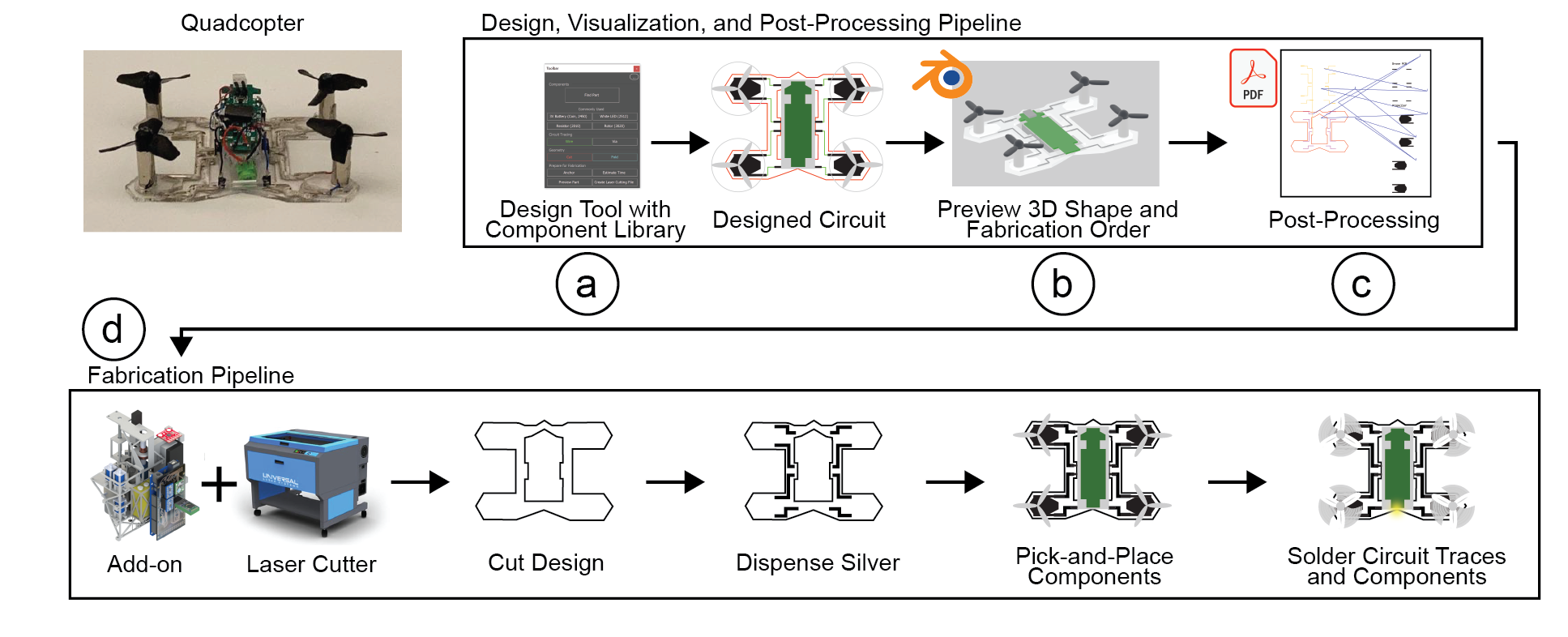

To support the creation of devices with LaserFactory, we provide the end-to-end fabrication pipeline shown in Figure 7. It consists of a design and visualization tool as well as a post-processing script that converts the design file into a set of machine instructions for fabricating the device with LaserFactory on the augmented laser cutter. The design tool lets users create 2D designs using drawing tools for the geometry (‘cut’, ‘fold’), the circuit traces (‘wire’), and for placing electronic components (‘place part’). This allows users to concurrently design the geometry and the electronic circuit. The accompanying visualization tool renders both the final 2D or 3D design and allows users to animate each step of the fabrication process. This assists users who may find it difficult to visualize the abstract 2D drawing. In addition, it allows users to inspect the order of each step in the fabrication process. On export, our post-processing script automatically translates the design file into machine instructions. Users do not have to add any explicit instructions for the add-on.

Figure 7. LaserFactory Pipeline: (a) Design Tool: Users place components, and draw geometry and circuit traces. (b) Visualization Tool: Users can preview the design in 3D and visualize the fabrication steps for debugging the design. (c) Post-Processing: On export, the design file is converted into machine instructions for the augmented laser cutter. (d) Fabrication: The augmented laser cutter then executes the post-processed file, i.e. cuts the geometry, dispenses silver for circuit traces, pick-and-places components, and then cures the silver to make the traces conductive and solders the components. Once fabricated, the device is fully functional.

Design Tool

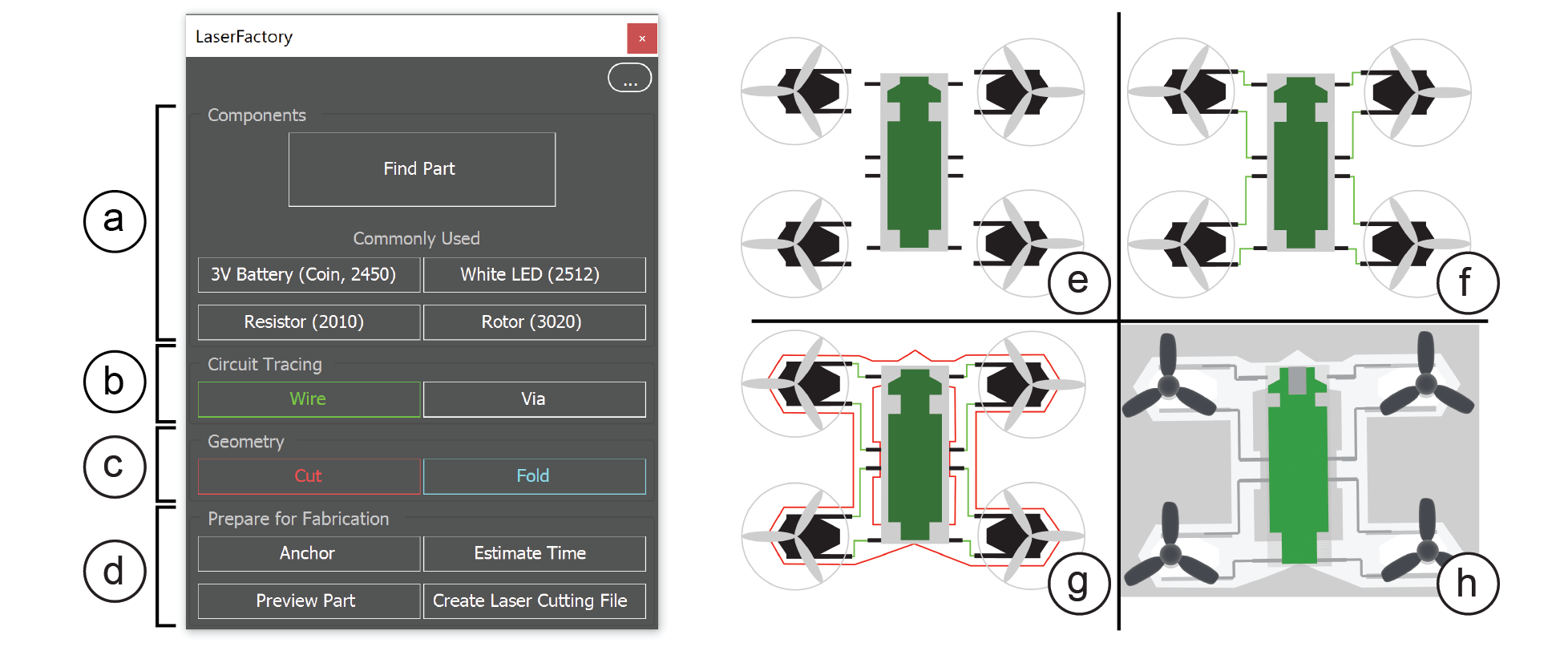

Our design tool (developed as a plugin to the 2D editor Adobe Illustrator) supports users in placing components, drawing circuit traces and designing the geometry of their devices. Figure 8a shows the toolbar of our design tool, which has the following functionality.

Electronic component library: To facilitate circuit design, users can select electronic components from a library of parts. Common components can be accessed directly from the toolbar and others can be found using the 'find part' button that opens the component library (Figure 8a). After selecting a component, it is loaded as a 2D representation onto the canvas (Figure 8b). Components appear as their physical footprint superimposed with their electronic symbol. Seeing the electronic components allows users to appraise the size of the main geometry in their design and adjust the design as needed.

Wire drawing tool: LaserFactory offers a wire drawing tool (Figure 8b), which is used to connect electronic components with traces. While free-form traces are possible, we enforce the wire tool to snap to 0/90° in order to align signaling motion with trace geometry for cleaner fabrication. Traces can also snap to the electrodes of components on approach to them, ensuring good electrical connections during fabrication. In the drawing, circuit traces are differentiated from other types of lines by color coding them in green (Figure 8g).

Geometry drawing tools: The LaserFactory user interface offers two drawing tools to define the geometry of the object (Figure 8c): the cut drawing tool and the bend drawing tool. In the drawing, cut lines are visualized in red and bend lines are visualized in cyan. For bending, users only have to indicate where to bend, but not in which order, which is taken care of by our post-processing script. For bending, users must use the 'anchor' tool to assign a section as the anchor plane which constrains this section as the one that remains planar in the event of folding.

Export tools: Finally, the interface includes a set of tools for use on completion of the design (Figure 8d). The "estimate time" tool parses the file to estimate the total fabrication time that is then displayed in the view. The 'Preview Part' tool opens the visualization tool, which we describe in more detail in the next section. Finally, the 'create laser cutting file' tool post-processes the design for fabrication and generates the final fabrication file.